Joint bearing testing device

A joint bearing and test device technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of low service life of rolling bearings, low mandrel life, and force bending, etc., so as to improve life, improve mandrel life, and reduce the number of replacements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

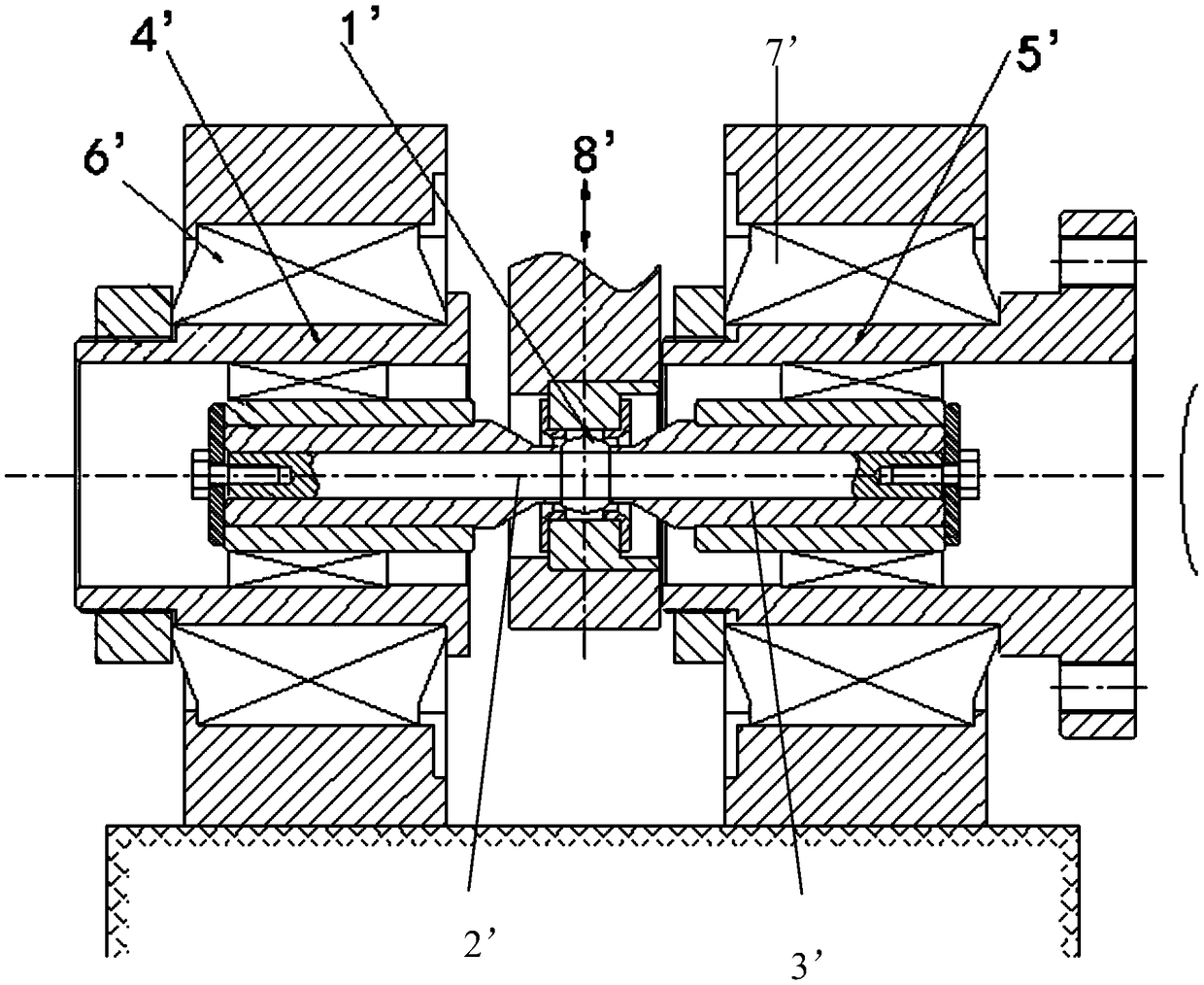

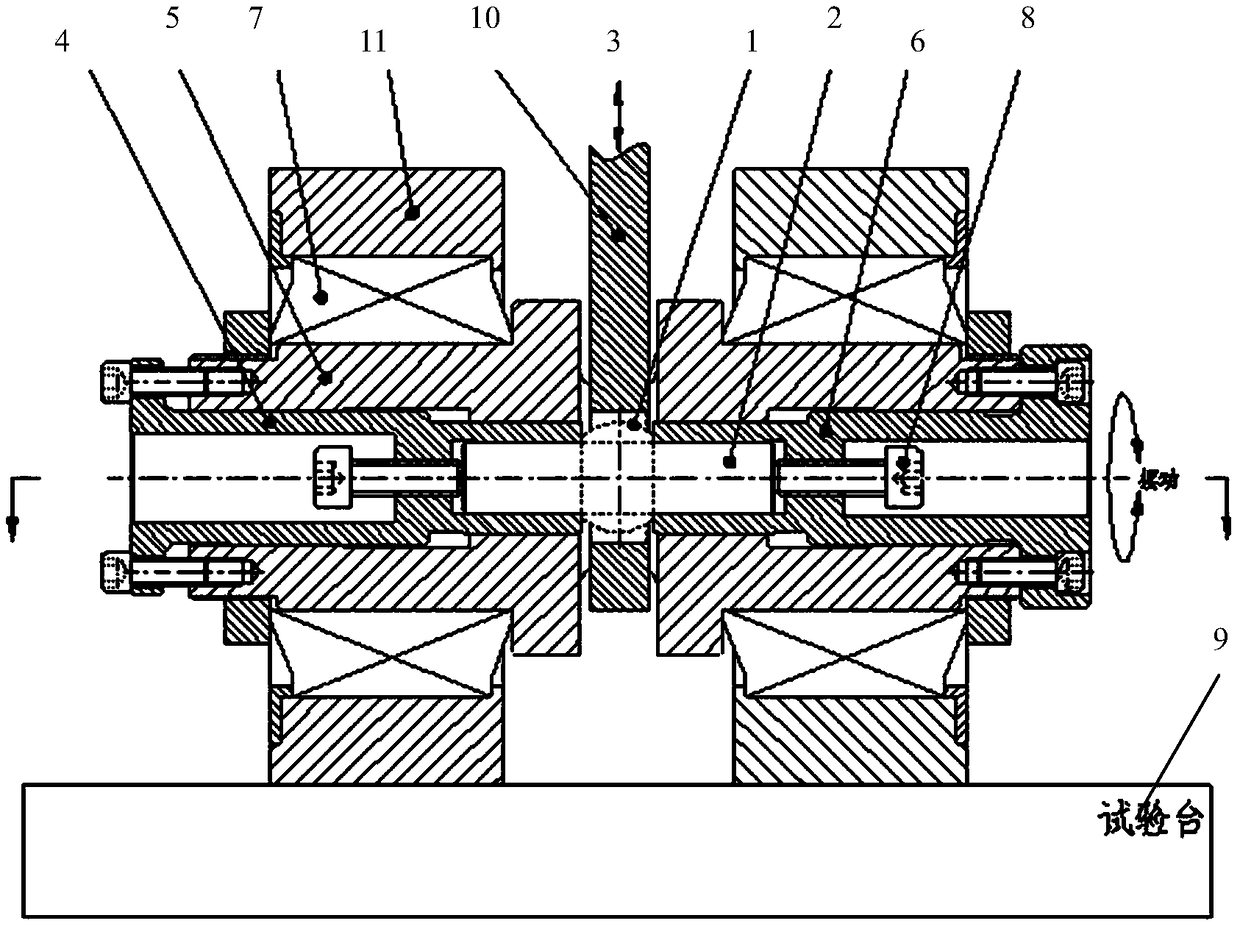

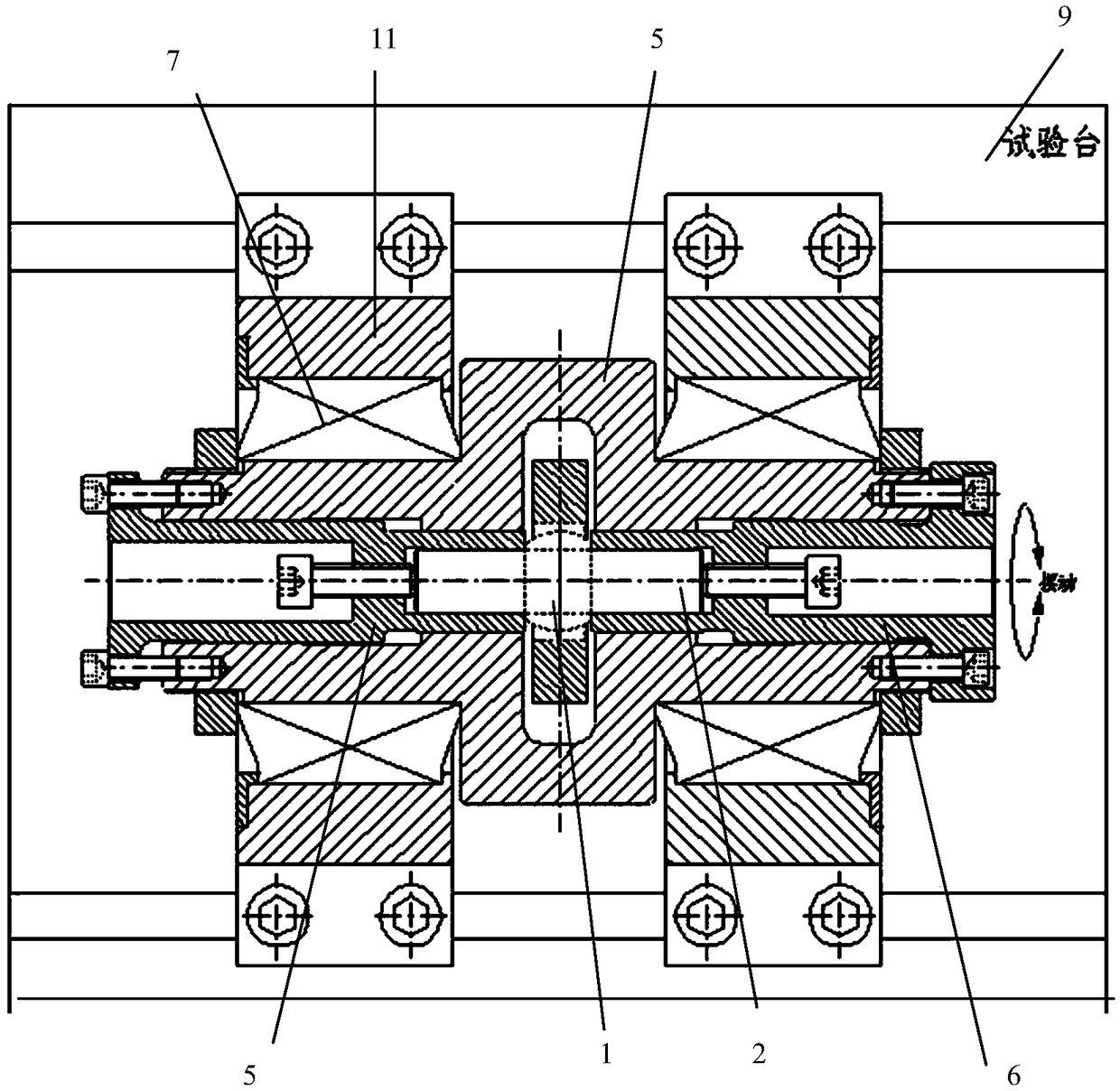

[0022] Examples, see Figure 1 to Figure 3 As shown, a joint bearing test device of the present invention includes a joint bearing 1, a mandrel 2, a load 3, a main rotating sleeve 4, a left sleeve 5, a right sleeve 6 and a rolling bearing 7; the mandrel 2 passes through In the inner ring hole of the joint bearing 1, the two ends of the mandrel 2 are respectively socketed inside the left bushing 5 and the right bushing 6, and the left bushing 5 and the right bushing 6 are respectively socketed In the main rotary sleeve 4, in this embodiment, the main rotary sleeve 4, the left and right shaft sleeves 5 and 6, and the mandrel 2 adopt interference fit or small clearance fit. The outside of the left bushing 5 and the right bushing 6 are provided with axial screw holes, and the tension screw 8 pushes the mandrel 2 inside the left bushing 5 or the right bushing 6 through the screw holes, Tighten the screw 8 to fine-tune the position and pre-tightening force; the two ends of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com