Automatic detection machine for perpendicularity and height of mute key

A verticality and detection machine technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of not being suitable for large-scale continuous production, large fluctuations in placement accuracy, and affecting measurement accuracy, so as to reduce the cost of the structure High precision in size and placement, no fluctuation in placement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

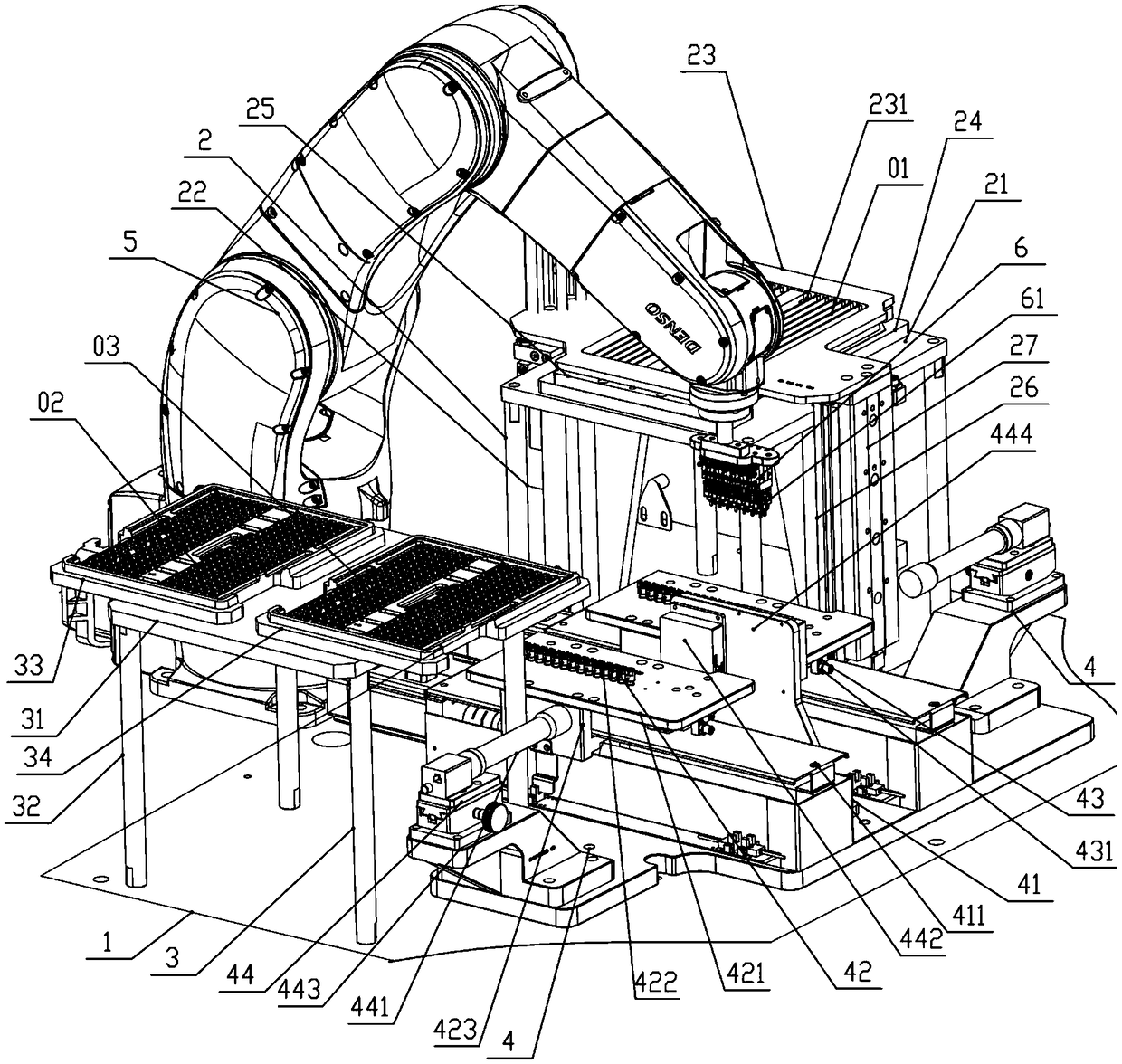

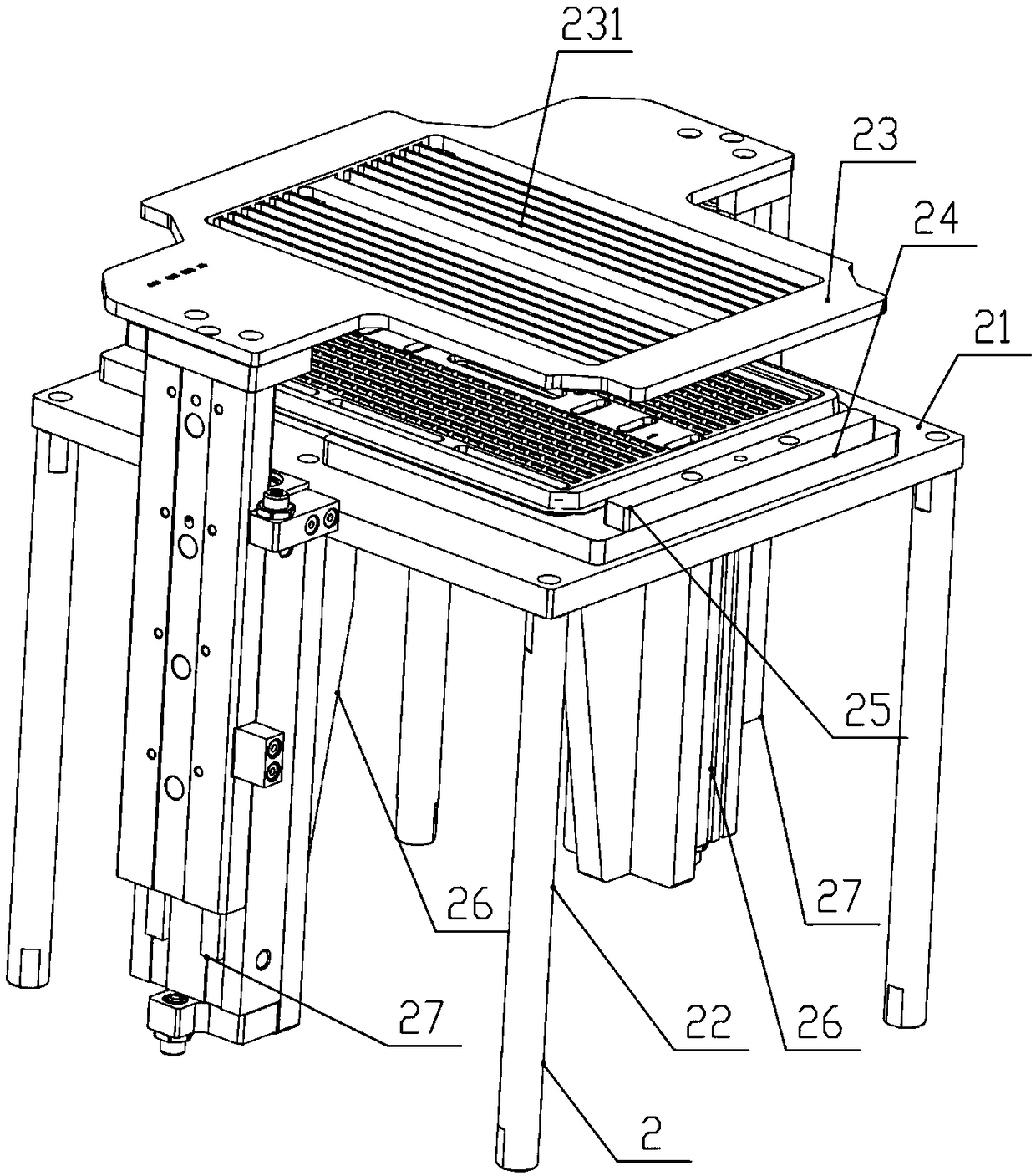

[0043] Figure 1 to Figure 9It schematically shows an automatic detection machine for the verticality height of the mute key according to an embodiment of the present invention. As shown in the figure, the device includes a workbench 1, and a loading part 2 is fixed on the front end of the workbench 1. The feeding part 2 can place the first blister tray 01, and the first blister tray 01 is loaded with processed The product 04, the other side of the front end of the workbench 1 is fixed with the blanking part 3, and the blanking part 3 can place the good product blist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com