Turbocharging system with internally-fitted assisting electric motor and cooling system thereof

A technology of turbocharging system and exhaust turbine, which is applied to internal combustion piston engines, mechanical equipment, combustion engines, etc., can solve the problems of slow response, slow response of engines and vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Description of the preferred embodiment

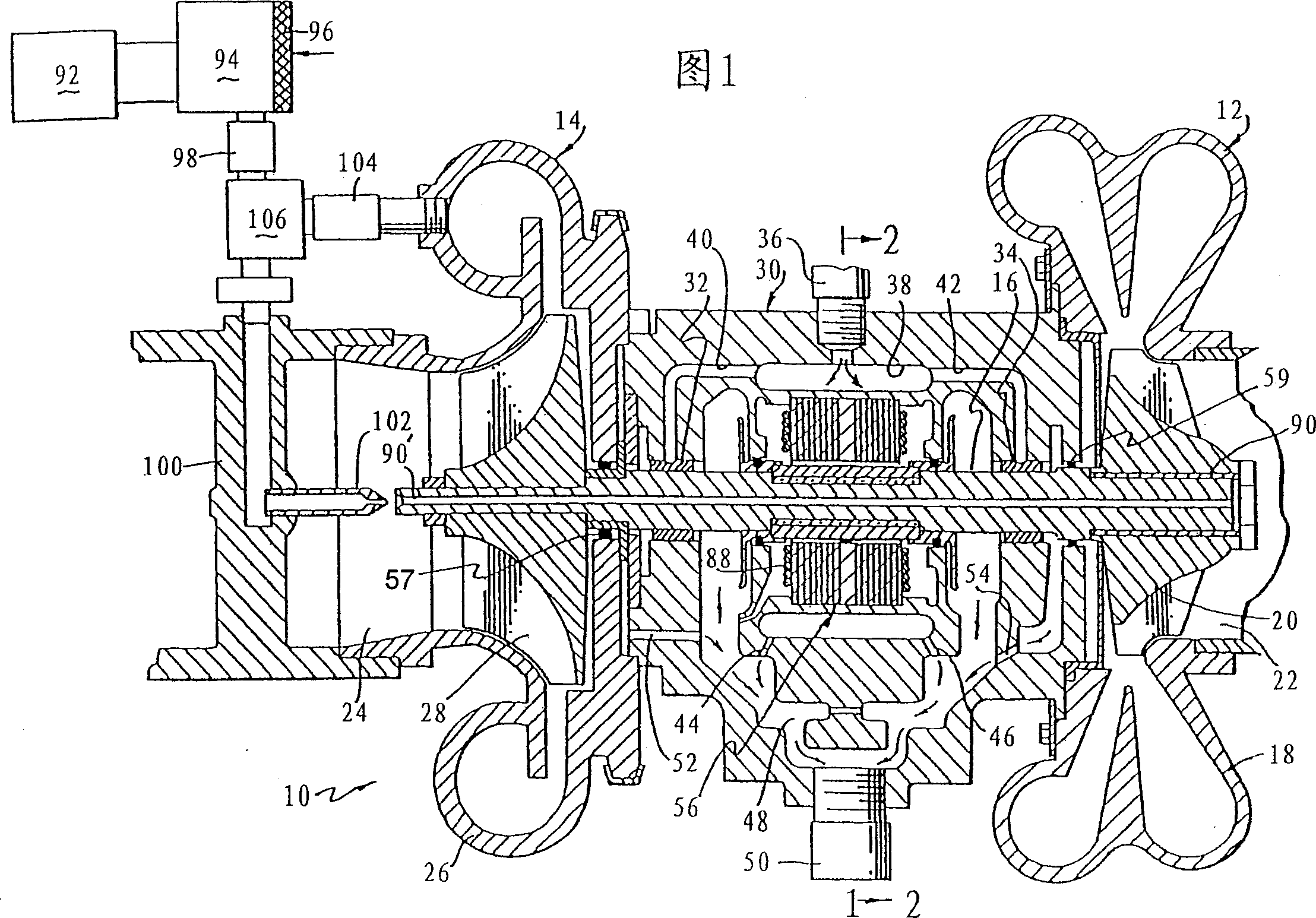

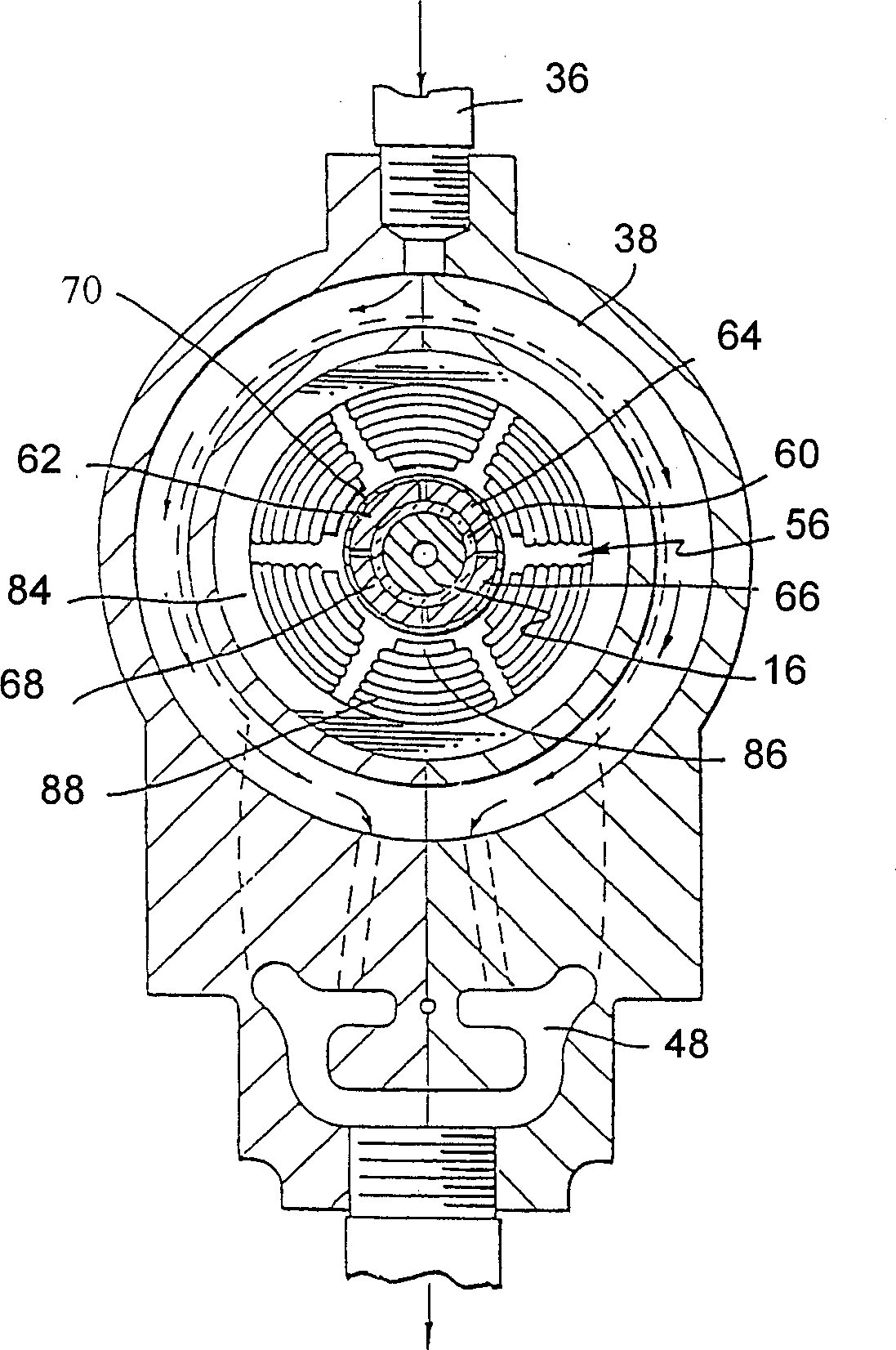

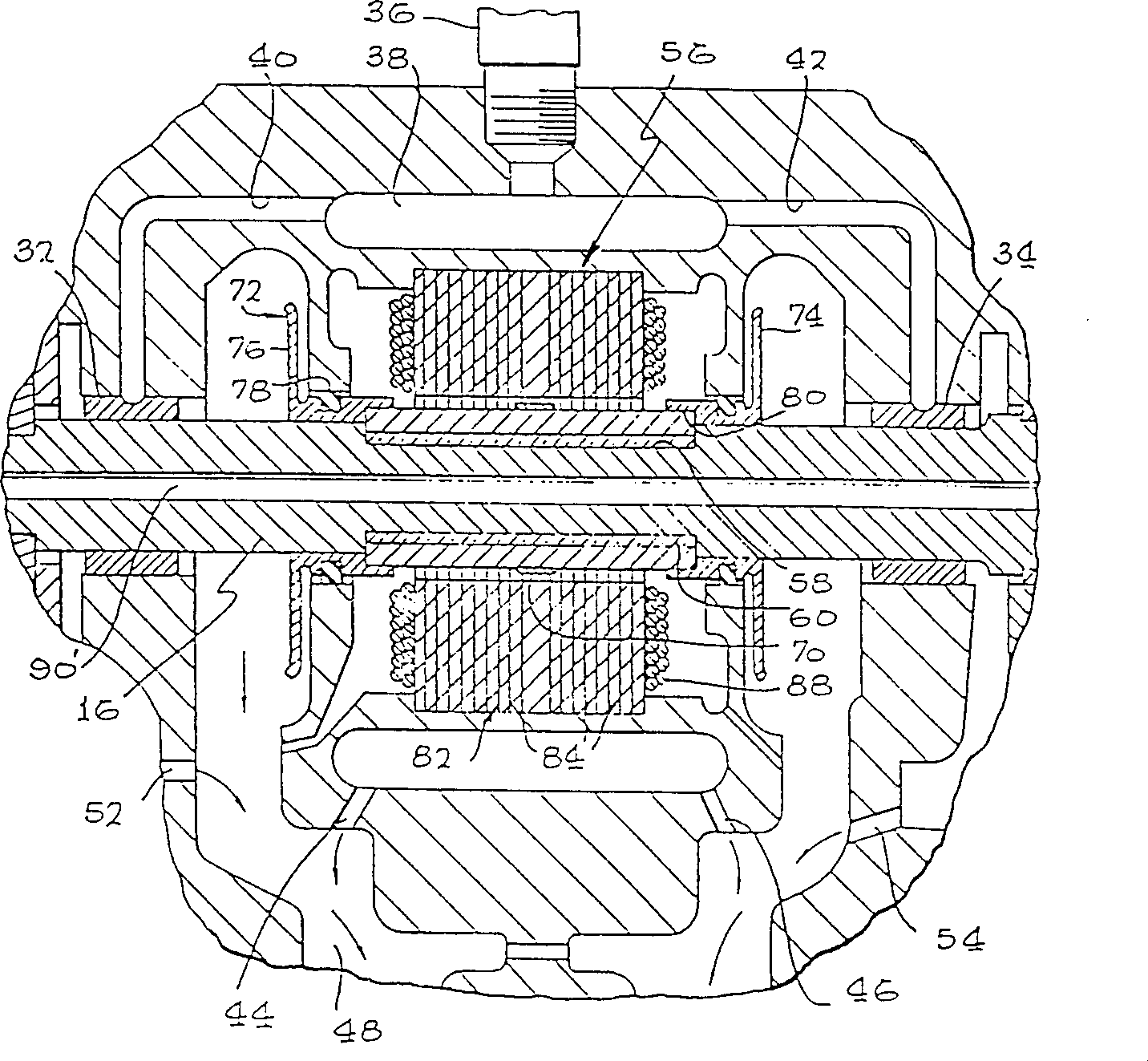

[0054]The turbocharging system of the present invention is indicated generally at 10 in FIG. 1 . The exhaust turbine 12 and charge compressor 14 are most clearly shown in longitudinal section along the centerline of the connecting shaft 16 of the exhaust turbine 12 and charge compressor 14 . The exhaust turbine has an inlet scroll 18 which is connected to receive exhaust gases from an internal combustion engine, such as a diesel engine. The impeller 20 is mounted on the shaft 16 and expands the exhaust gases. Exhaust gas is discharged out of the exhaust pipe 22 . The impeller 20 applies a torque to the shaft 16 and causes the shaft 16 to rotate.

[0055] At the other end of the shaft, an air inlet 24 receives air from the outside after passing through an air filter or similar device which removes a substantial portion of physical contaminants. The intake port 24 is part of a turbocharger that includes a scroll 26 . A compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com