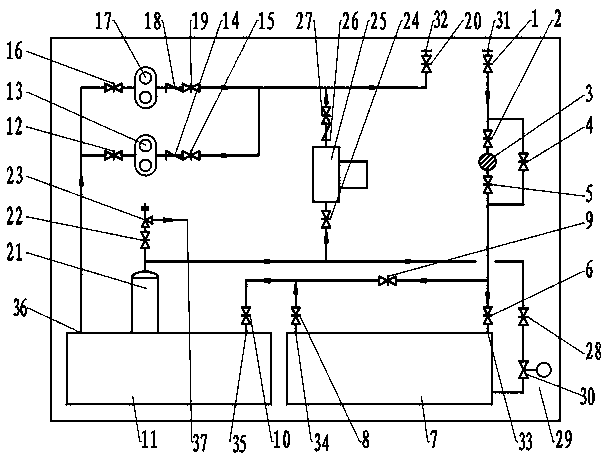

A kind of oil-gas separation mixed transportation pressurized skid and its technology

A technology of pressurized skid and mixed transportation, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as environmental pollution, uneconomical gas pipelines, and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] There are two main processes for the oil-gas separation, mixed-transportation and pressurization skid, one is crude oil heating, buffering, separation, pressurization and mixed-transportation, and the other is crude oil buffering, separation, pressurization and mixed-transportation. Supercharged mixed transmission means that the working status of two oil delivery pumps is one for use and the other for standby. One oil delivery pump is started during normal work, and the other oil delivery pump is standby, or the other pump is started at a certain interval, and the two pumps are switched to work in turn. When one of the pumps fails to start the other oil delivery pump, the faulty pump needs to be replaced in time, and the valves at the inlet and outlet of the pump should be closed when replacing or overhauling the pump. The filter 3 needs to be cleaned regularly, and the incoming oil goes through the bypass pipe during cleaning, and the filter pipe is restored in time aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com