Hot water conveying hose

A technology for conveying hoses and hot water, applied in the directions of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of inconvenient use and easy damage of hoses, and achieve the advantages of improving service life, reducing friction and reducing noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

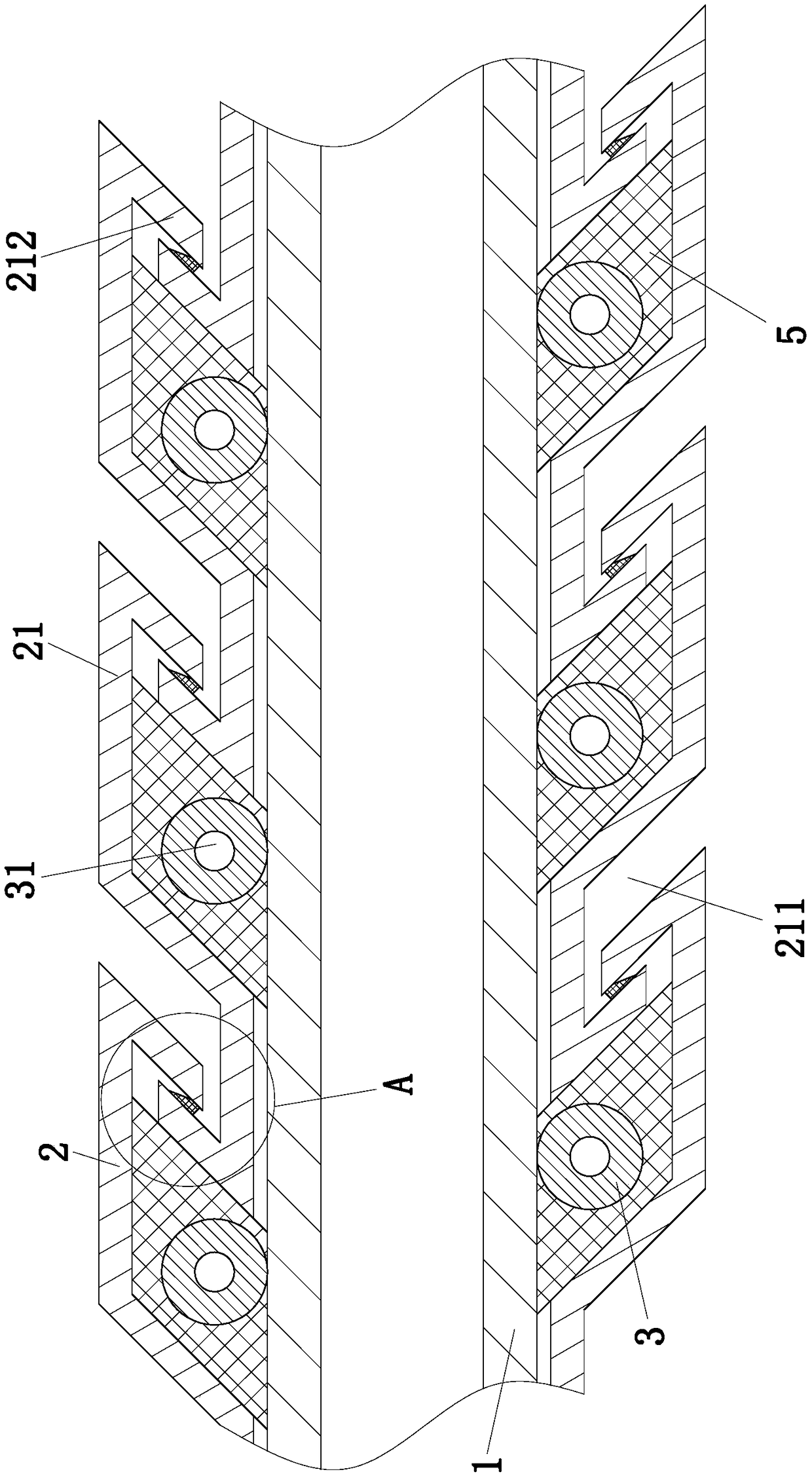

[0018] use Figure 1-Figure 3 A hot water transport hose according to one embodiment of the present invention will be described below.

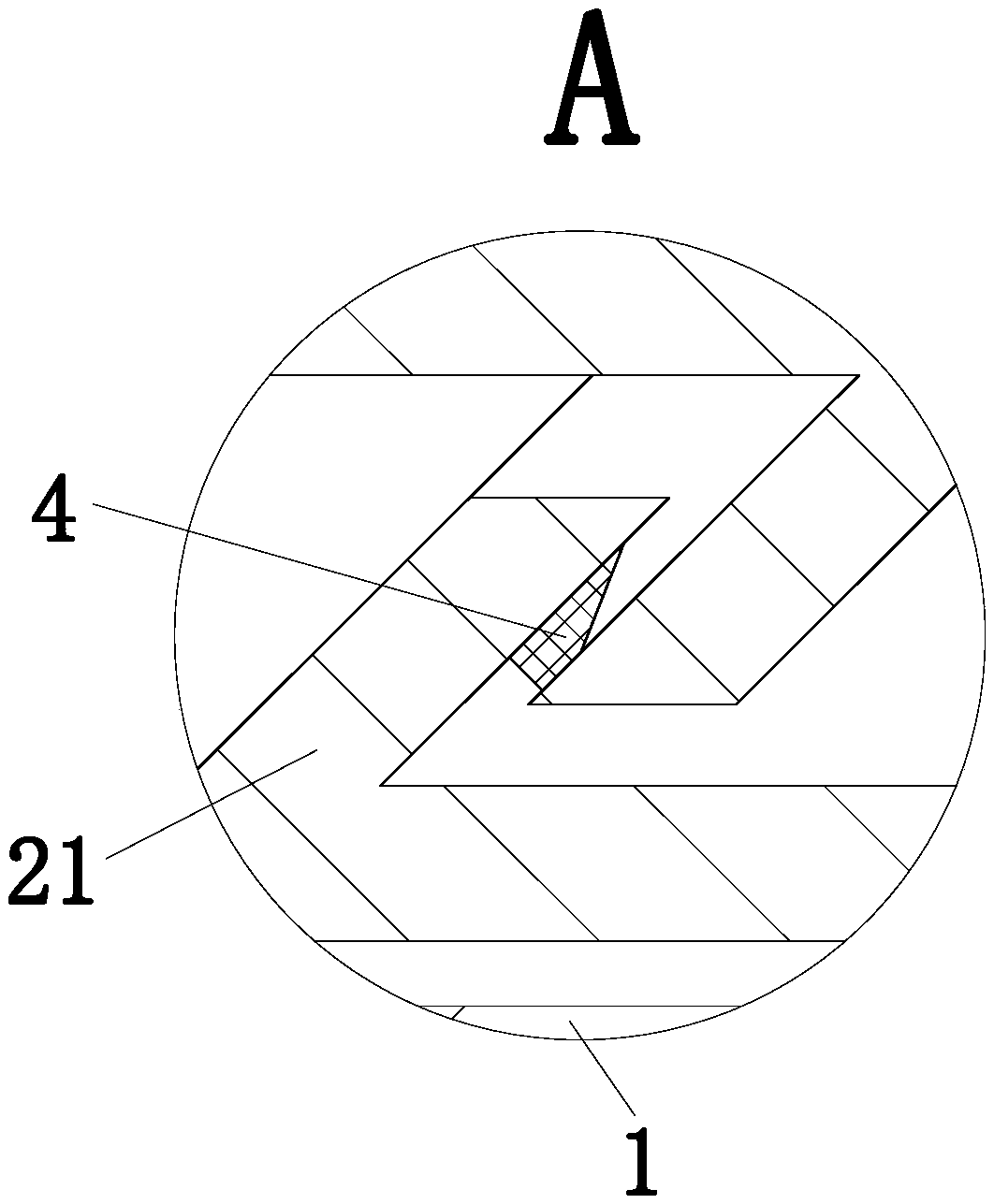

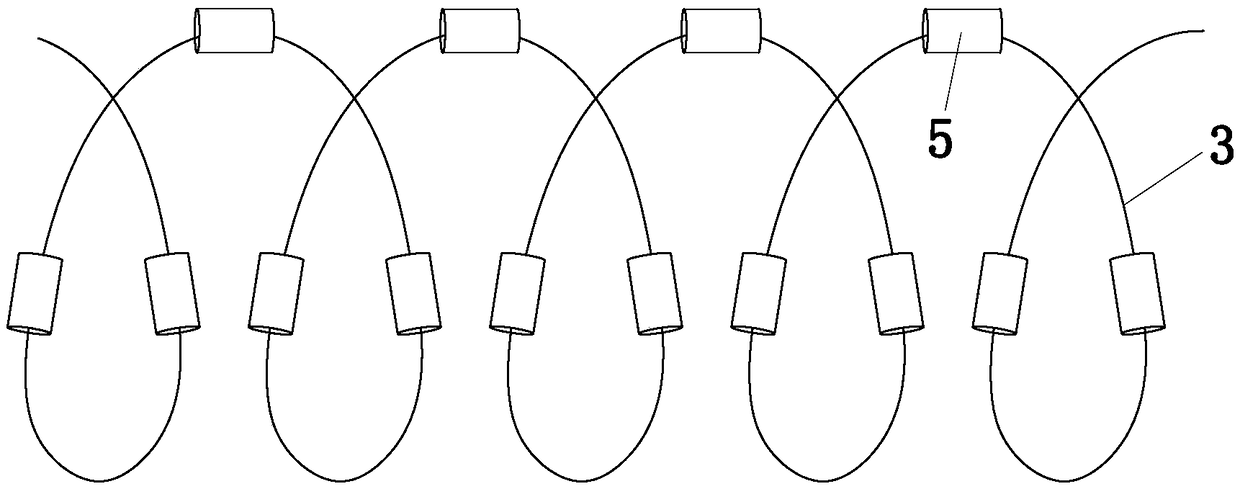

[0019] like figure 1 As shown, a hot water delivery hose according to the present invention includes an inner tube 1 and an outer tube 2, the outer tube 2 is an elastic metal strip 21; the surface of the metal strip 21 is provided near one end with a groove 211, the surface of the metal strip 21 near the other end is provided with a boss 212 in the same direction as the groove 211, the metal strip 21 is spirally wound on the outer peripheral surface of the inner tube 1 to wrap the inner tube 1, the metal strip 21 There is a part of overlap between two adjacent turns, and the boss 212 of the metal strip 21 is attached to the side wall of the groove 211 at the overlapping position; the outer peripheral surface of the inner tube 1 is also wound with a spring 3, and each spring 3 The circles are evenly distributed between the groove 211 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com