Multi-factor coupling passive control technology inhibiting blade tip clearance flow loss of radial flow turbine

A technology of coupling control and blade tip clearance, which is applied to engine components, machines/engines, and leakage prevention, etc., can solve the problems of radial turbine blade tip clearance flow structure types, low operating efficiency, and large gap flow loss, etc., to achieve Effects of suppression of interstitial flow loss, improvement of operating efficiency, and enhancement of working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

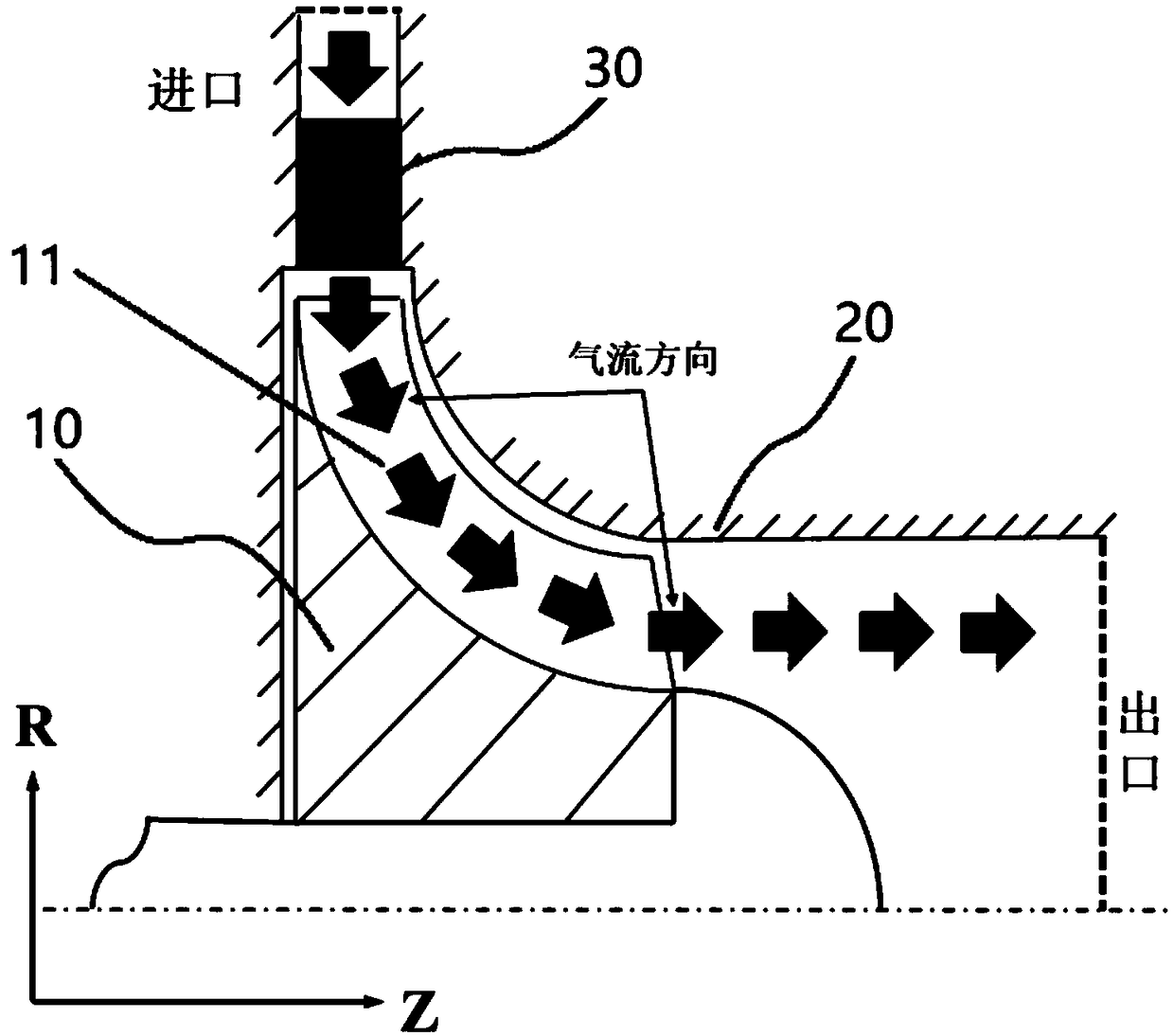

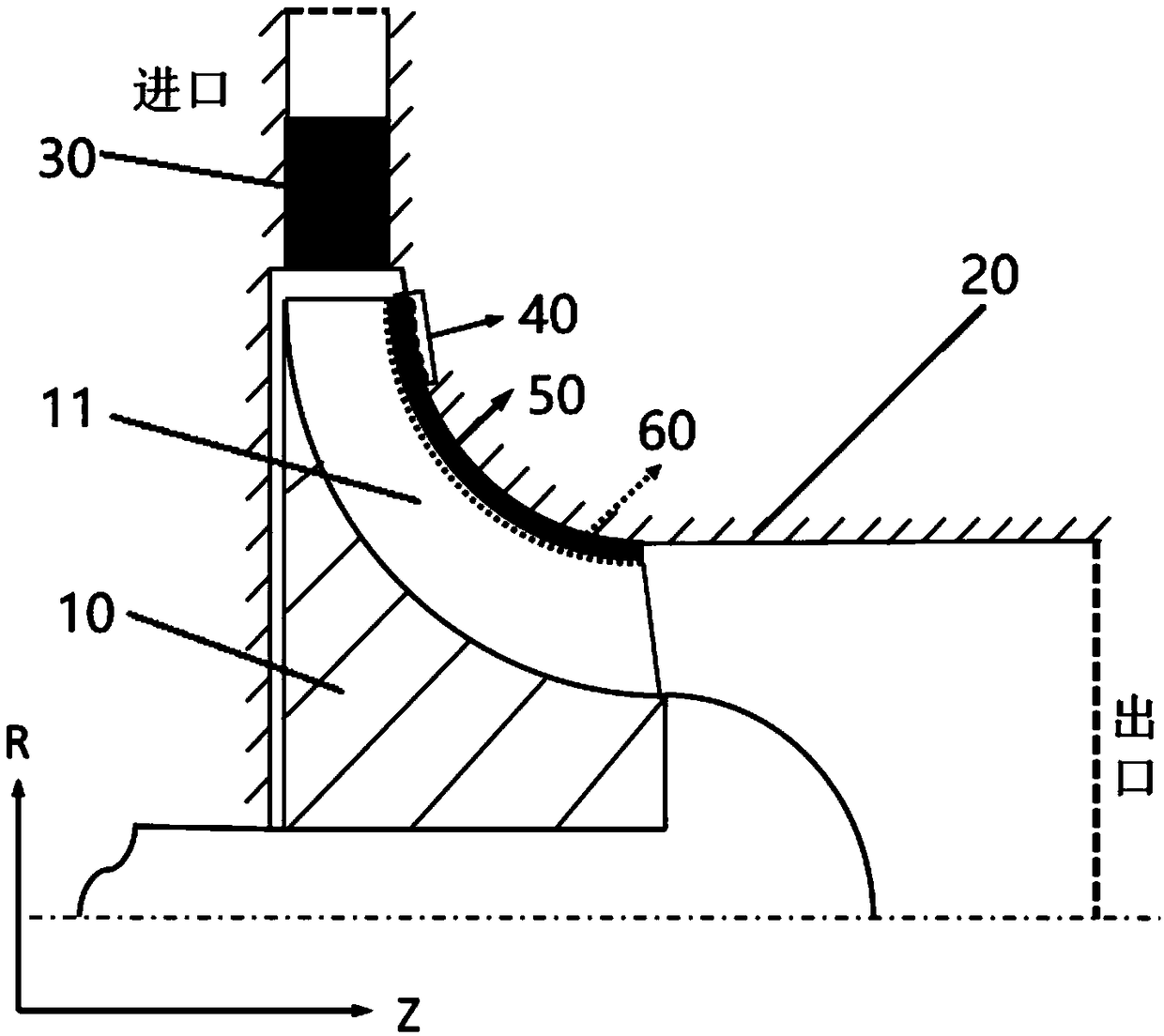

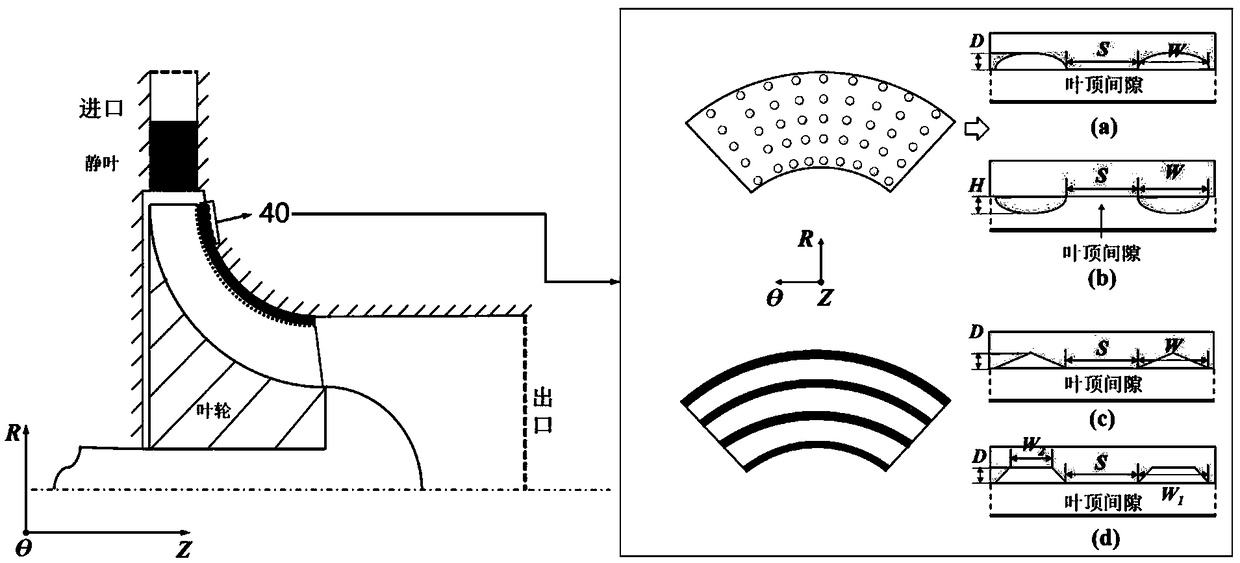

[0035] Such as figure 1 As shown, the radial flow turbine includes a radial flow impeller 10 and a casing 20. The radial flow impeller 10 is coaxially arranged in the casing 20. The radial flow impeller 10 is evenly distributed along its circumference with a plurality of radial flow blades 11. There is a tip clearance between the cassettes 20 . Turbine vanes 30 may further be provided upstream of the radial turbine. The radial flow turbine can be a centripetal type, a mixed flow type turbine, etc., and the radial flow turbine can be of a single-stage or multi-stage structure. The number, geometric shape, structural size and rotational speed of the radial flow turbines are determined with the design parameters. When the working fluid flows in the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com