Screw expansion (compression) machine with variable volume ratio

A screw expander, volume ratio technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of the expander deviating from the best matching state, the high cost of heat recovery and development system equipment, and the high manufacturing cost of the expander , to reduce the irreversible loss of thermodynamics, improve the overall operating efficiency, and increase the net output power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

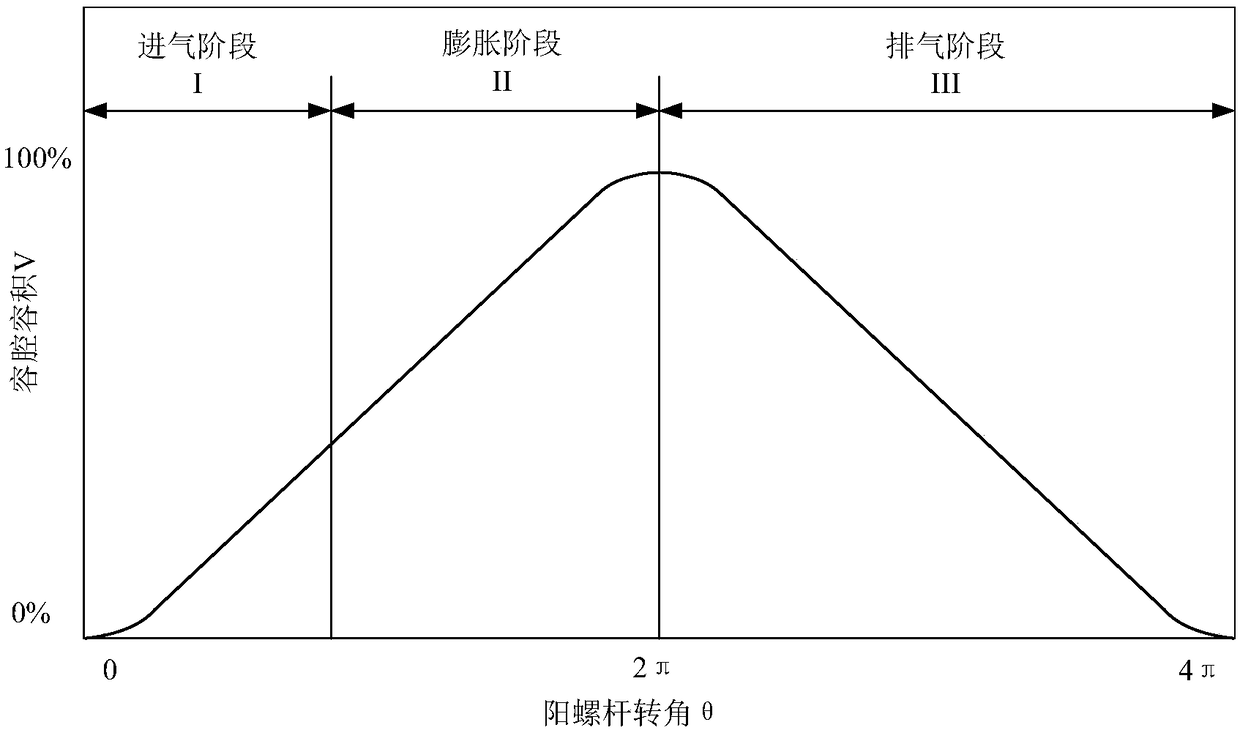

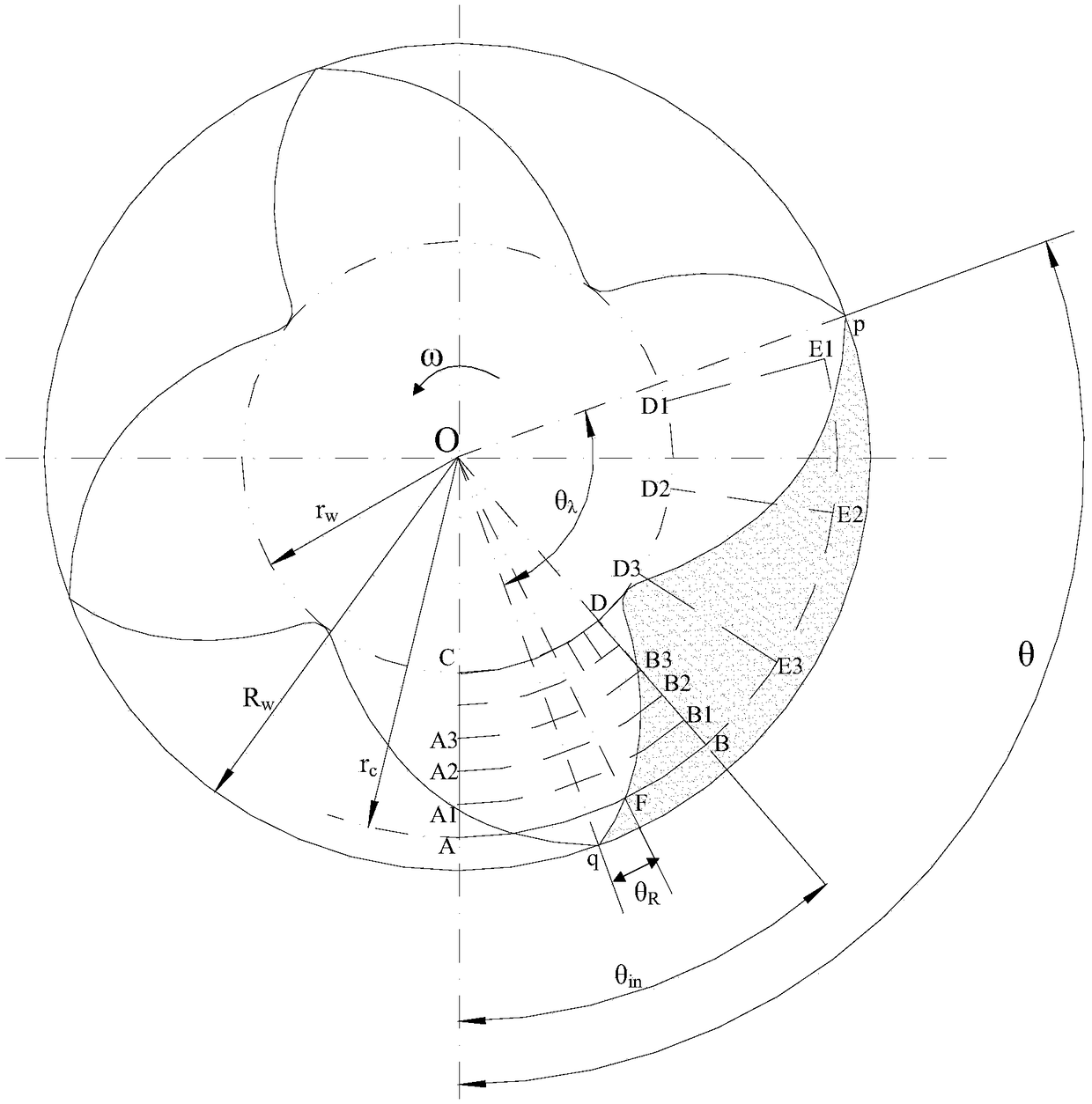

[0049] From the working principle of the screw expander, it can be known that the volume V of the cavity between the screw teeth of the screw expander is a function V(θ) of the male screw rotation angle θ, such as figure 1 As shown, during the rotation of the male screw, the screw cavity goes through the intake stage, expansion stage, and exhaust stage in sequence. Wherein, when the air intake ends, the expansion starts, and at this time, the air inlet is cut off and closed by the helical tooth section of the male screw. According to the characteristics of the screw expander, such as figure 1 As shown, there is a nonli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com