Hemispherical support node and manufacturing process thereof

A manufacturing process and technology of hemispheres, which are applied in the direction of architecture and building construction, can solve the problems of support node quality influence, instability, uneven reaction force, etc., and achieve improved stability and safety, uniform reaction force, and work efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

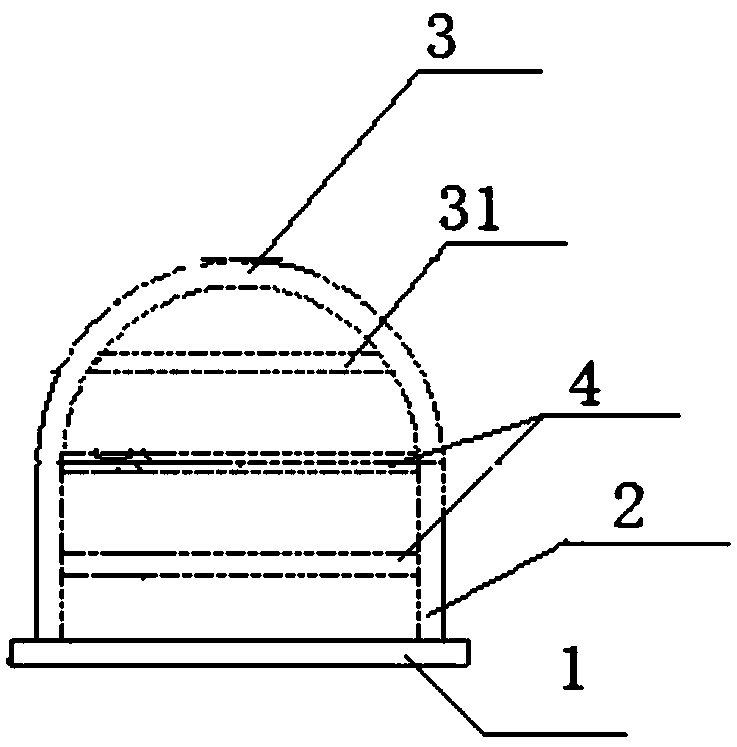

[0038] A hemispherical support node as shown in the figure includes: a support base plate 1, a circular tube 2 and a hemisphere 3, the circular tube 2 is arranged above the support base plate 1, and the hemispherical body 3 is arranged on a circle Above the tube 2 , a stiffening auxiliary plate 31 is provided inside the hemisphere 3 , and a set of stiffening plates 4 are provided inside the round tube 2 .

[0039] The hemisphere 3 in this embodiment is a hollow hemisphere.

[0040] In this embodiment, the hemisphere 3 is provided with a beveled surface.

Embodiment 2

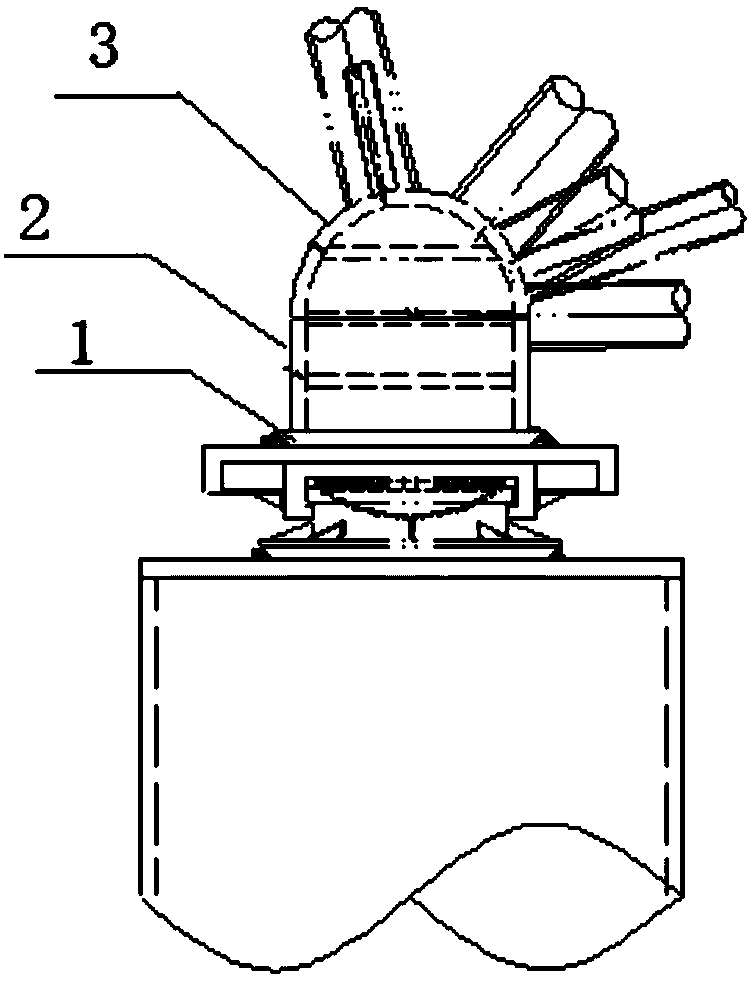

[0042] A hemispherical support node as shown in the figure includes: a support base plate 1, a circular tube 2 and a hemisphere 3, the circular tube 2 is arranged above the support base plate 1, and the hemispherical body 3 is arranged on a circle Above the tube 2 , a stiffening auxiliary plate 31 is provided inside the hemisphere 3 , and a set of stiffening plates 4 are provided inside the round tube 2 .

[0043] The hemisphere 3 in this embodiment is a hollow hemisphere.

[0044] In this embodiment, the hemisphere 3 is provided with a beveled surface.

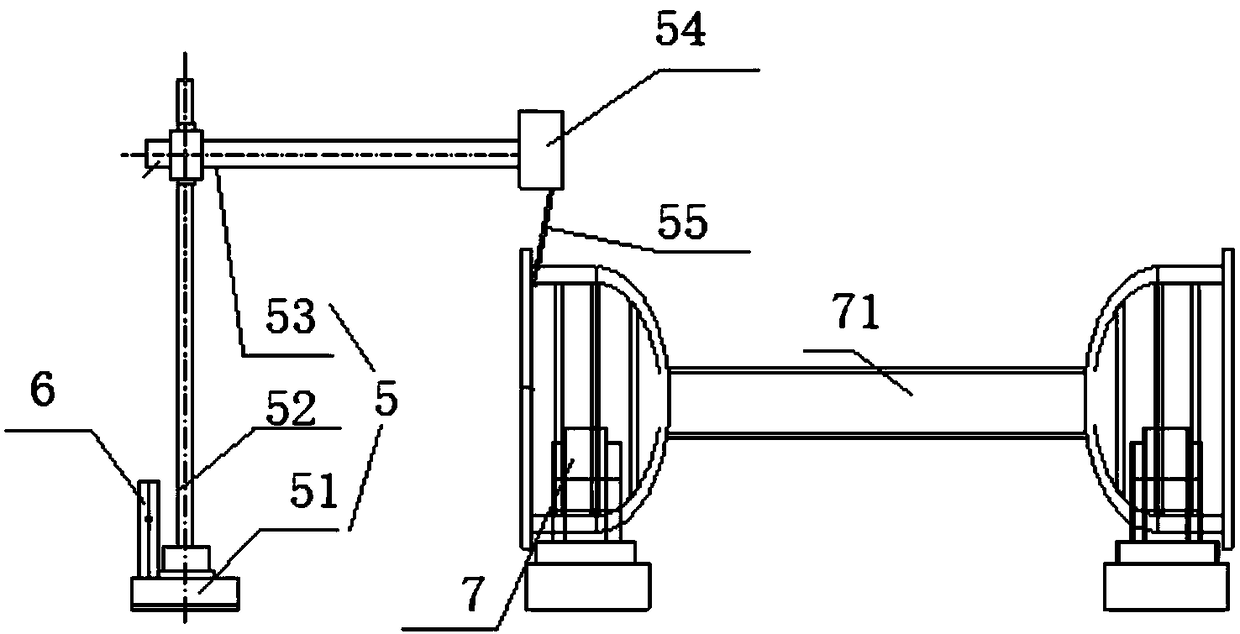

[0045] This embodiment also includes a welding automatic manipulator for welding hemispherical support nodes, which is characterized in that it includes: a welding manipulator 5, an electrical control box 6 and a group of roller frames 7 for supporting the hemispherical support nodes , the welding manipulator 1 is provided with a base 51, a column 52 and a cross bar 53, the column 52 is located on the base 51, the cross bar ...

Embodiment 3

[0047]A hemispherical support node as shown in the figure includes: a support base plate 1, a circular tube 2 and a hemisphere 3, the circular tube 2 is arranged above the support base plate 1, and the hemispherical body 3 is arranged on a circle Above the tube 2 , a stiffening auxiliary plate 31 is provided inside the hemisphere 3 , and a set of stiffening plates 4 are provided inside the round tube 2 .

[0048] The hemisphere 3 in this embodiment is a hollow hemisphere.

[0049] In this embodiment, the hemisphere 3 is provided with a beveled surface.

[0050] This embodiment also includes a welding automatic manipulator for welding hemispherical support nodes, which is characterized in that it includes: a welding manipulator 5, an electrical control box 6 and a group of roller frames 7 for supporting the hemispherical support nodes , the welding manipulator 1 is provided with a base 51, a column 52 and a cross bar 53, the column 52 is located on the base 51, the cross bar 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com