Fabric three-dimensional fixing device and method thereof

A fabric and equipment technology, applied in the field of fabric three-dimensional setting equipment, can solve the problems of rough edges, loose fabric edges, time-consuming and labor-intensive, etc., to save time, improve production efficiency, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

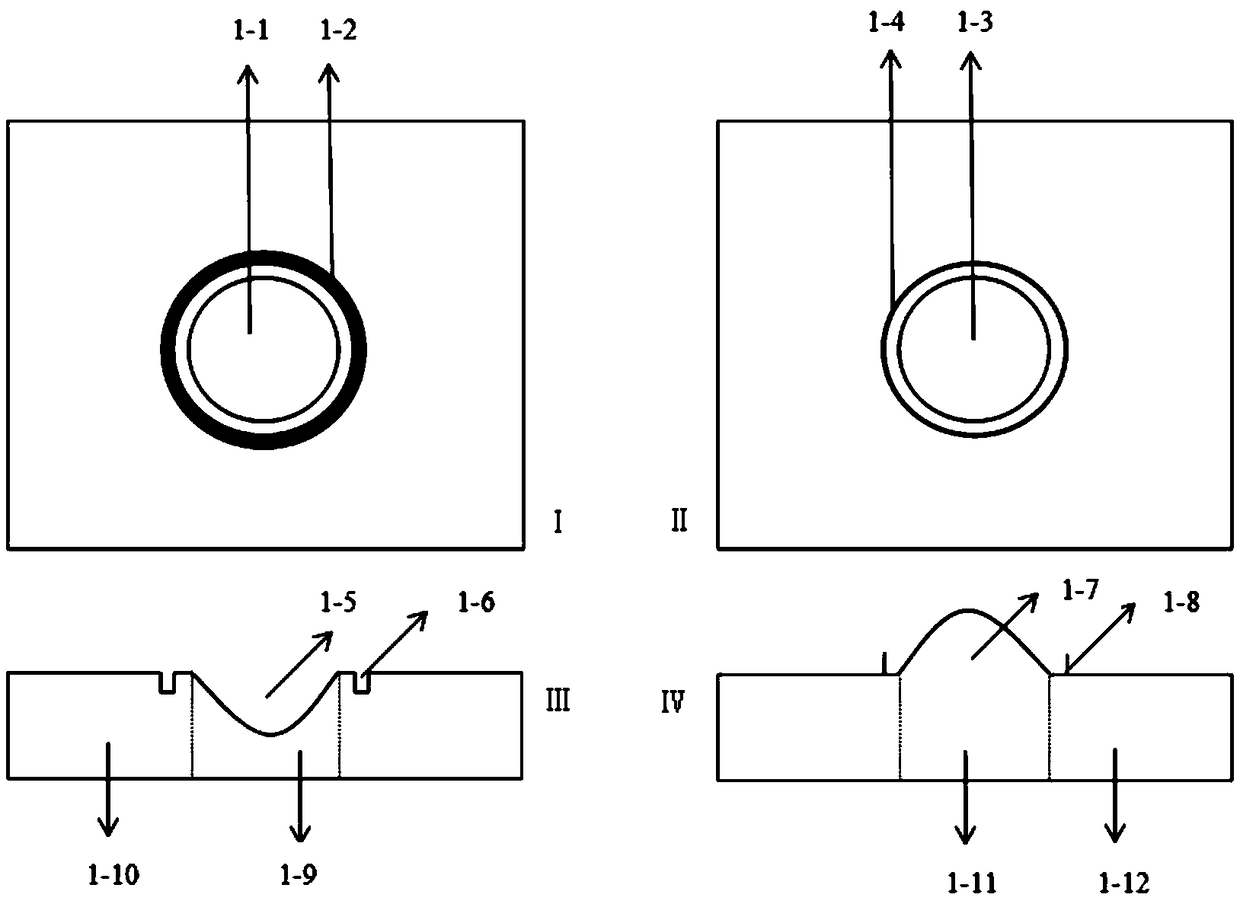

[0032] This embodiment provides a fabric three-dimensional shaping equipment, including an upper mold and a lower mold, see figure 1 , the upper and lower molds respectively include a heat setting zone and a cutting zone; and the working temperature of the cutting zone of the upper and lower molds is higher than the working temperature of the heat setting zone.

[0033] The resistance value of the metal material used in the cutting zone of the upper and lower molds is higher than the resistance value of the metal material used in the heat setting zone of the upper and lower molds.

[0034] The heat-setting zone and the cutting zone of the upper mold are respectively made of metal materials with different resistance values, and the heat-setting zone and the cutting zone of the lower mold are respectively made of metal materials with different resistance values; and the upper The heat setting area of the mold and the heat setting area of the lower mold are made of metal mate...

Embodiment 2

[0046] This embodiment provides a method for three-dimensional shaping of fabrics, the method comprising:

[0047] The fabric to be style-cut is cut into a predetermined size and shape corresponding to the size and shape of the upper and lower moulds.

[0048] Place the cut fabric flat on the surface of the concave part of the lower mould;

[0049] Make the fabric three-dimensional shaping equipment in the working state, the upper mold is lowered until the convex part of the upper mold and the concave part of the lower mold are seamlessly matched;

[0050] Heat setting operation of the fabric through the upper and lower molds;

[0051] After the heat setting operation is completed, the fabric is cut through the upper and lower molds;

[0052] The upper and lower molds are separated to complete the demoulding operation.

[0053] This method can be applied to hernia repair materials.

[0054] Specifically, this embodiment is described by taking the application in hernia repa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com