A pre-welding cleaning device for automobile metal plates

A technology for cleaning devices and metal plates, which is applied in the field of auto parts processing devices to achieve the effects of eliminating stress, improving measurement accuracy, and improving continuity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

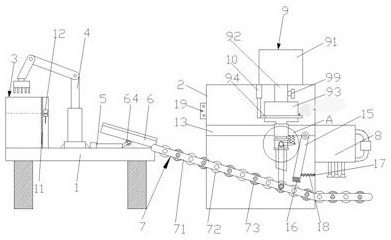

[0032] refer to figure 1 , a cleaning device for automobile metal plates before welding, including a base 1 and a box body 2, the top of the base 1 is connected with a measuring cylinder 3, a mechanical arm 4, a first electric telescopic rod 5 and a weighing assembly 6 in sequence along the horizontal direction, and the box The body 2 is provided with a control panel 19, the measuring cylinder 3 is connected with an isolation plate 11, and an opening is provided on the isolation plate 11, and the inner cavity of the measuring cylinder 3 is divided into a large liquid storage chamber and a small liquid storage chamber by the isolation plate 11. A float type liquid level gauge 12 is provided in the small liquid storage chamber, and the end of the weighing component 6 away from the first electric telescopic rod 5 is movably connected to the base 1, and the side of the base 1 close to the box body 2 is connected to a conveying component 7, And the conveying assembly 7 extends outw...

Embodiment 2

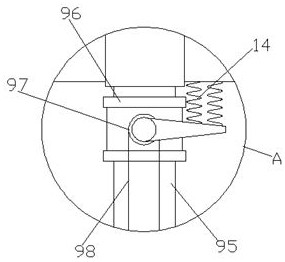

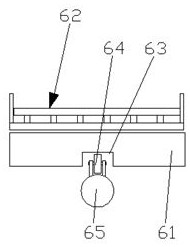

[0034] refer to Figure 1-4, a kind of automobile metal plate cleaning device before welding, is basically the same as embodiment 1, the difference is that the weighing assembly 6 includes a weighing gauge 61, the casing 2 is provided with a control panel 19, and the top of the weighing gauge 61 is connected to There is a sliding assembly 62, a chute 63 is provided at the bottom of the weighing scale 61, a pulley 64 is slidably connected in the chute 63, and the pulley 64 is connected to the telescopic end of the first electric telescopic rod 5 through a bracket, and the sliding assembly 62 includes a bottom plate 621 And the top plate 622, the bottom plate 621 is connected on the weighing scale 61, the top of the top plate 622 is provided with a limit groove 623, the first roller shaft 624 evenly distributed is movably connected in the limit groove 623, and the bottom plate 621 and the top plate 622 are connected with a The water pipe 625, and the water pipe 625 runs through ...

Embodiment 3

[0036] refer to Figure 1-5 , a pre-welding cleaning device for an automobile metal plate, which is basically the same as that of Embodiment 2, the difference is that an electric heating tube 627 is sleeved inside the first roller shaft 624, which realizes the function of sliding and feeding the metal plate before welding. Annealed for stress relief.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com