A kind of preparation method of nano-titanium particle reinforced magnesium-based composite material

A technology of composite materials and nano-titanium, which is applied in the field of preparation of magnesium-based composite materials, can solve the problems of uneven distribution of nano-titanium particles, poor comprehensive mechanical properties, and unsatisfactory reinforcing effect of reinforcements, so as to facilitate dispersion and improve The effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

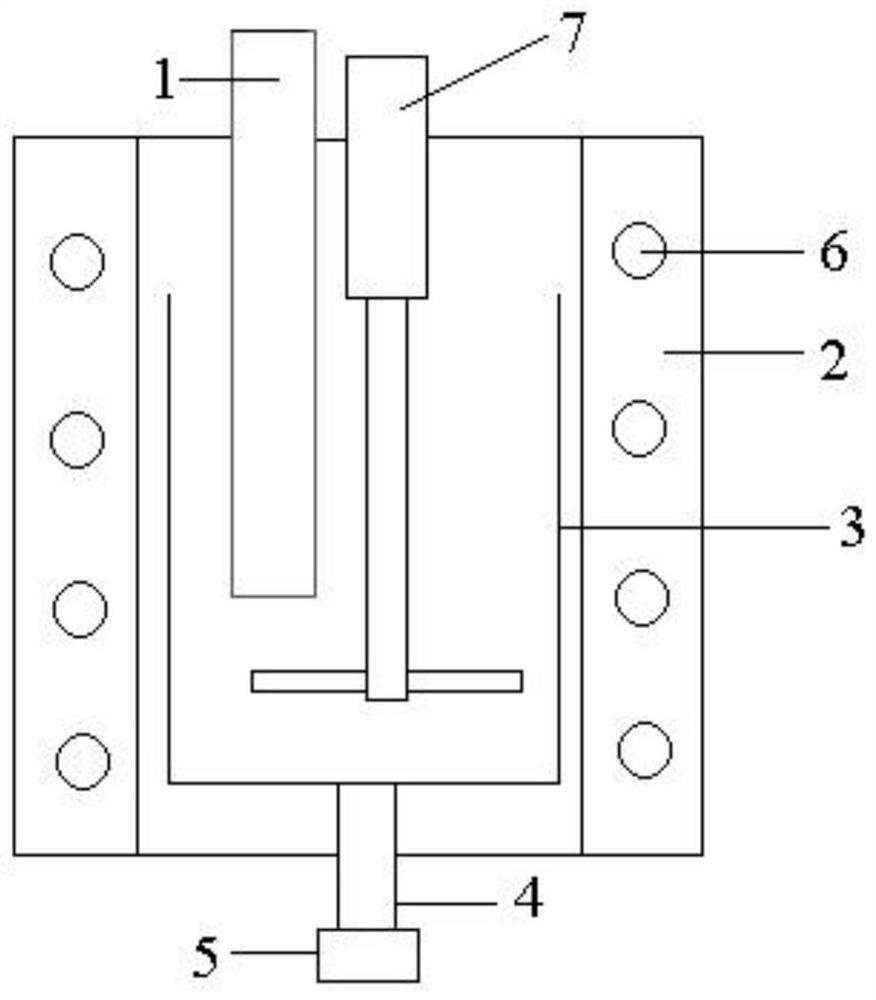

[0019] Specific implementation mode 1: This implementation mode is a preparation method of nano-titanium particle-reinforced magnesium-based composite material, which is specifically carried out according to the following steps:

[0020] 1. Melting of the matrix alloy and preheating of the nano-titanium particles of the reinforcement: put the magnesium alloy into the crucible, and then smelt it into a liquid magnesium alloy at a temperature of 720°C to 800°C; at the same time, put the nano-titanium particles at a temperature of Preheat for 20 minutes to 40 minutes at 150°C to 250°C;

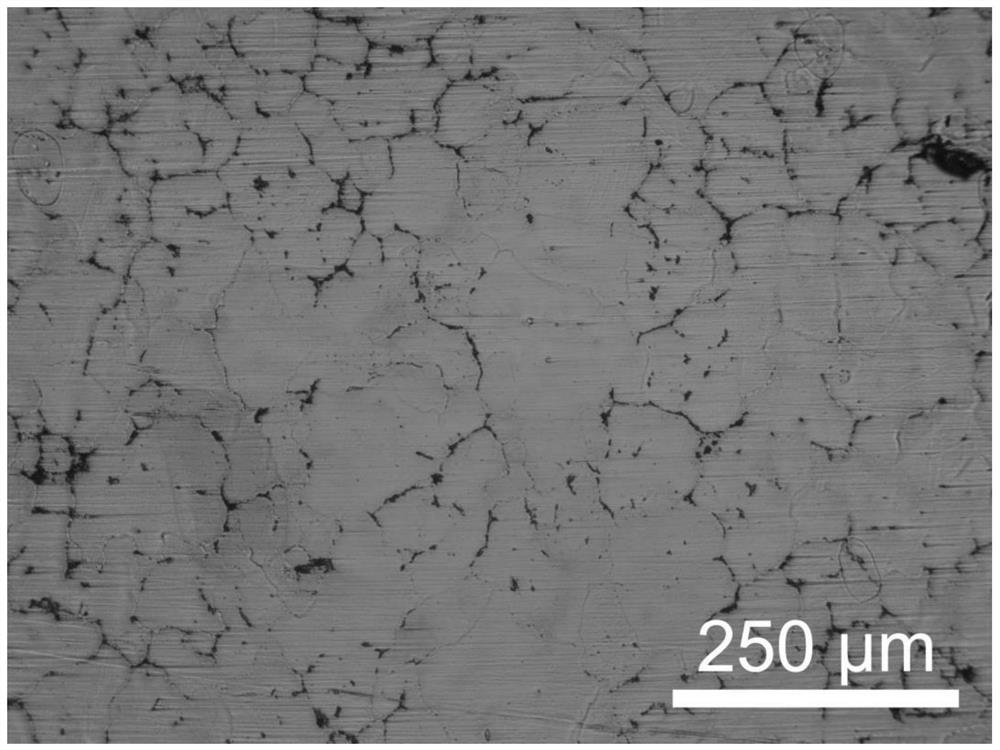

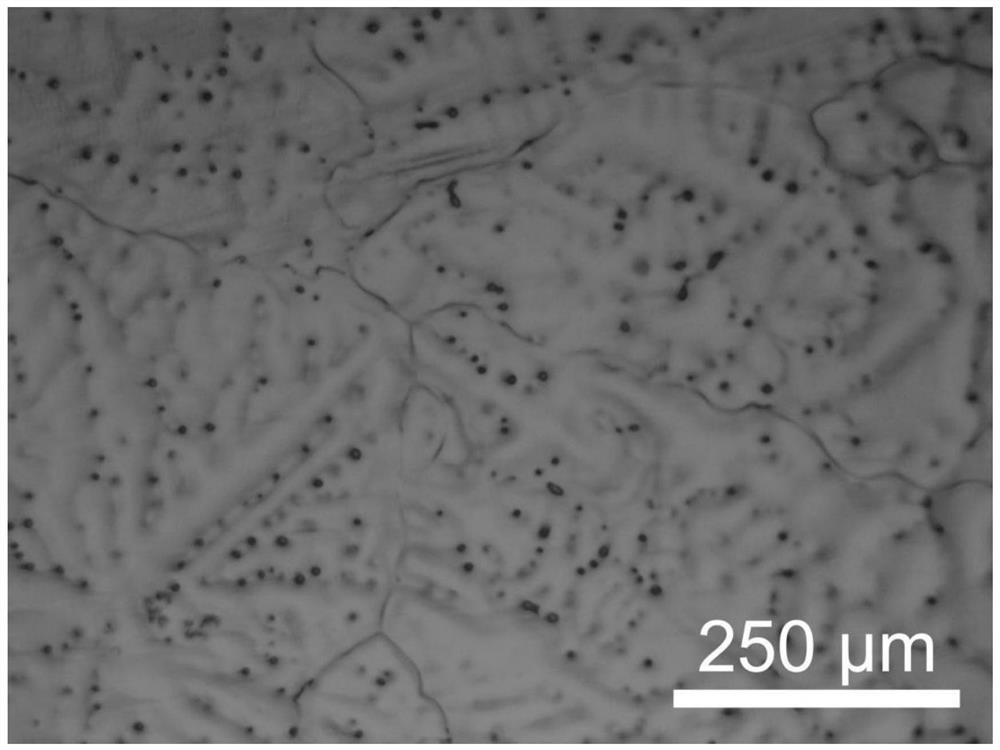

[0021] 2. Semi-solid stirring: the temperature of the liquid magnesium alloy in step 1 is lowered to 620°C to 660°C to obtain a semi-solid magnesium alloy. Add hot nano-titanium particles into the semi-solid magnesium alloy, and then continue to stir for 20-30 minutes under the conditions of differential forward and reverse stirring and magnesium alloy semi-solid, to obtain a semi-solid mixed mel...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the magnesium alloy described in step 1 is a microalloyed Mg-Zn alloy. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the titanium nanoparticles are preheated for 30 minutes at a temperature of 200° C. at the same time. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com