Fermentation method of organic fertilizer

A fermentation method and technology for organic fertilizers, which are applied in the preparation of organic fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve problems such as environmental hazards, impact on human and animal health, sustainable development of livestock breeding industry, and discharge of livestock manure, etc. Quality, prevention of damage to soil fertility, effect of shortening fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

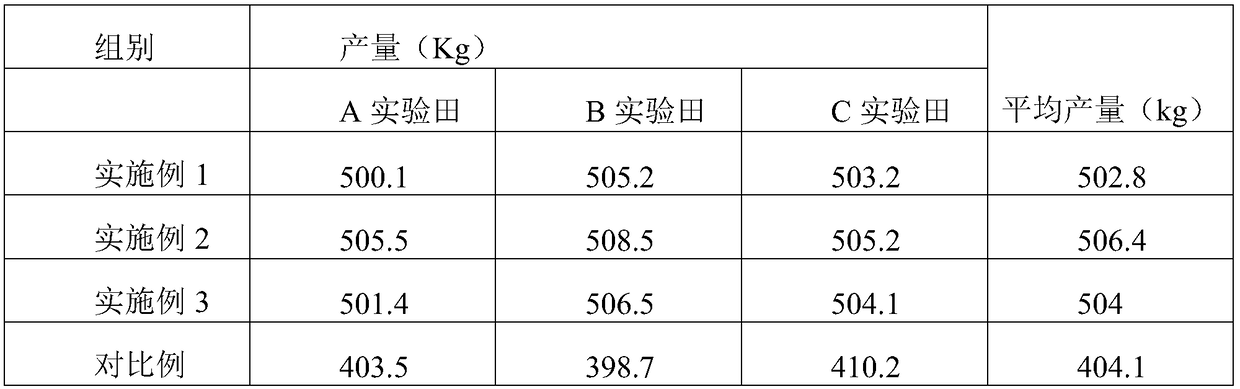

Embodiment 1

[0029] The present embodiment provides a kind of fermentation method of organic fertilizer, and the step comprises:

[0030] 1) Take 40-60 parts of straw powder, 20-30 parts of grass ash, 70-90 parts of farm manure, 50-70 parts of rice husk powder, 3-8 parts of biological bacteria agent, and 3-5 parts of superphosphate according to the parts by weight , the farmyard manure is mixed with cow manure, chicken manure and pig manure in a ratio of 2:2:1, and the biological bacteria agent includes: yeast, actinomycetes, photosynthetic bacteria and nitrogen-fixing bacteria;

[0031] 2) spread grass ash in the fermentation tank;

[0032] 3) In the re-fermentation tank, the first layer of straw powder is tiled with a thickness of 10-15 cm, the second layer of farmyard manure is tiled with a thickness of 8-12 cm, the third layer of rice husk powder is tiled with a thickness of 5-8 cm, and the fourth layer is tiled with rice husk powder with a thickness of 5-8 cm. Spread farmyard manure ...

Embodiment 2

[0042] The present embodiment provides a kind of fermentation method of organic fertilizer, and the step comprises:

[0043] 1) Take 40-60 parts of straw powder, 20-30 parts of grass ash, 70-90 parts of farm manure, 50-70 parts of rice husk powder, 3-8 parts of biological bacteria agent, and 3-5 parts of superphosphate according to the parts by weight , the farmyard manure is mixed with cow manure, chicken manure and pig manure in a ratio of 2:2:1, and the biological bacteria agent includes: yeast, actinomycetes, photosynthetic bacteria and nitrogen-fixing bacteria;

[0044] 2) spread grass ash in the fermentation tank;

[0045] 3) In the re-fermentation tank, the first layer of straw powder is tiled with a thickness of 10-15 cm, the second layer of farmyard manure is tiled with a thickness of 8-12 cm, the third layer of rice husk powder is tiled with a thickness of 5-8 cm, and the fourth layer is tiled with rice husk powder with a thickness of 5-8 cm. Spread farmyard manure ...

Embodiment 3

[0055] The present embodiment provides a kind of fermentation method of organic fertilizer, and the step comprises:

[0056] 1) Take 40-60 parts of straw powder, 20-30 parts of grass ash, 70-90 parts of farm manure, 50-70 parts of rice husk powder, 3-8 parts of biological bacteria agent, and 3-5 parts of superphosphate according to the parts by weight , the farmyard manure is mixed with cow manure, chicken manure and pig manure in a ratio of 2:2:1, and the biological bacteria agent includes: yeast, actinomycetes, photosynthetic bacteria and nitrogen-fixing bacteria;

[0057] 2) spread grass ash in the fermentation tank;

[0058] 3) In the re-fermentation tank, the first layer of straw powder is tiled with a thickness of 10-15 cm, the second layer of farmyard manure is tiled with a thickness of 8-12 cm, the third layer of rice husk powder is tiled with a thickness of 5-8 cm, and the fourth layer is tiled with rice husk powder with a thickness of 5-8 cm. Spread farmyard manure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com