Industrial wastewater treatment system

A technology for treating system and industrial wastewater, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., it can solve the problems of unguaranteed quality, control accuracy error, high price, and improve resource use. Efficiency, simple and reliable structure, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

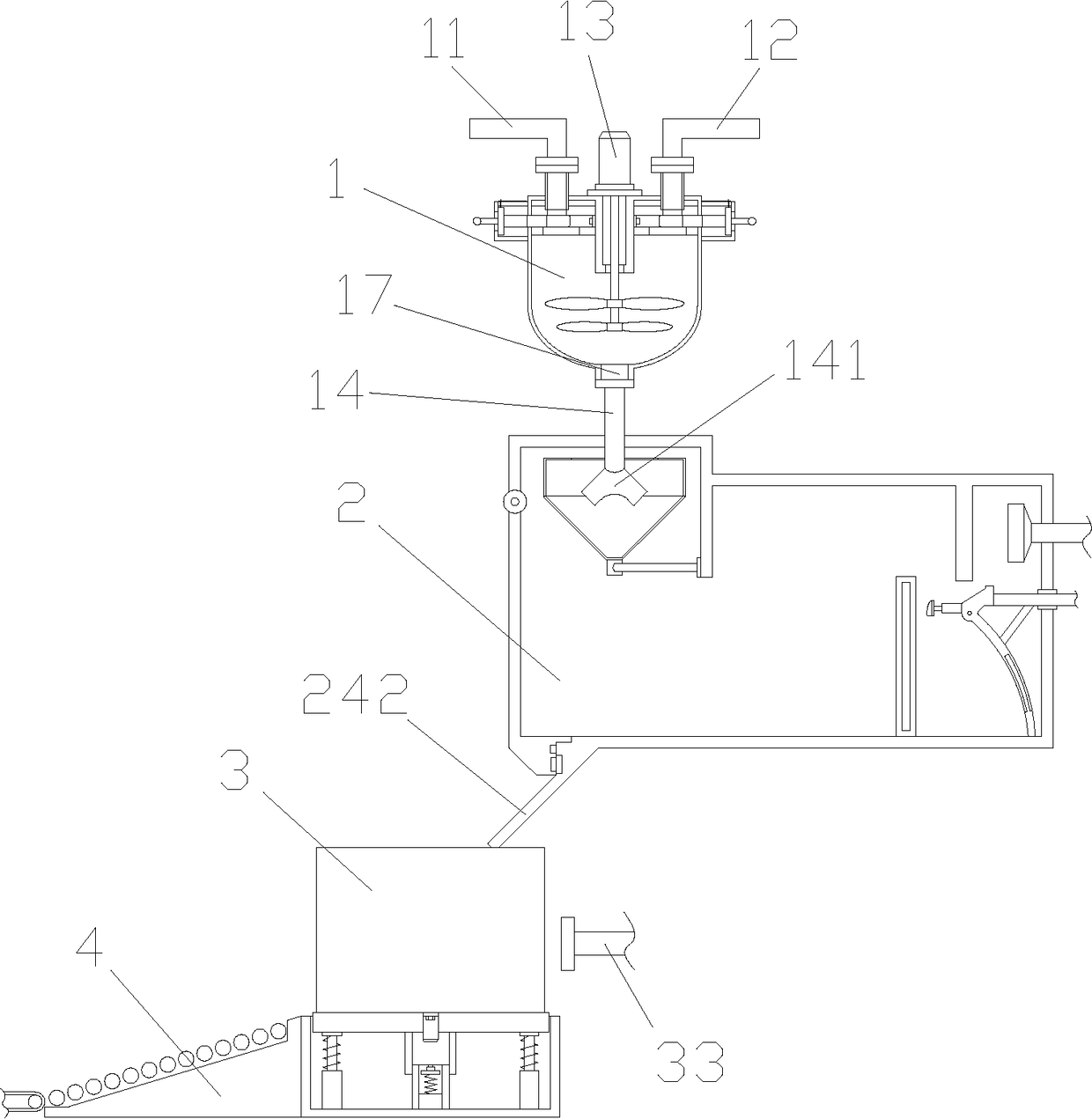

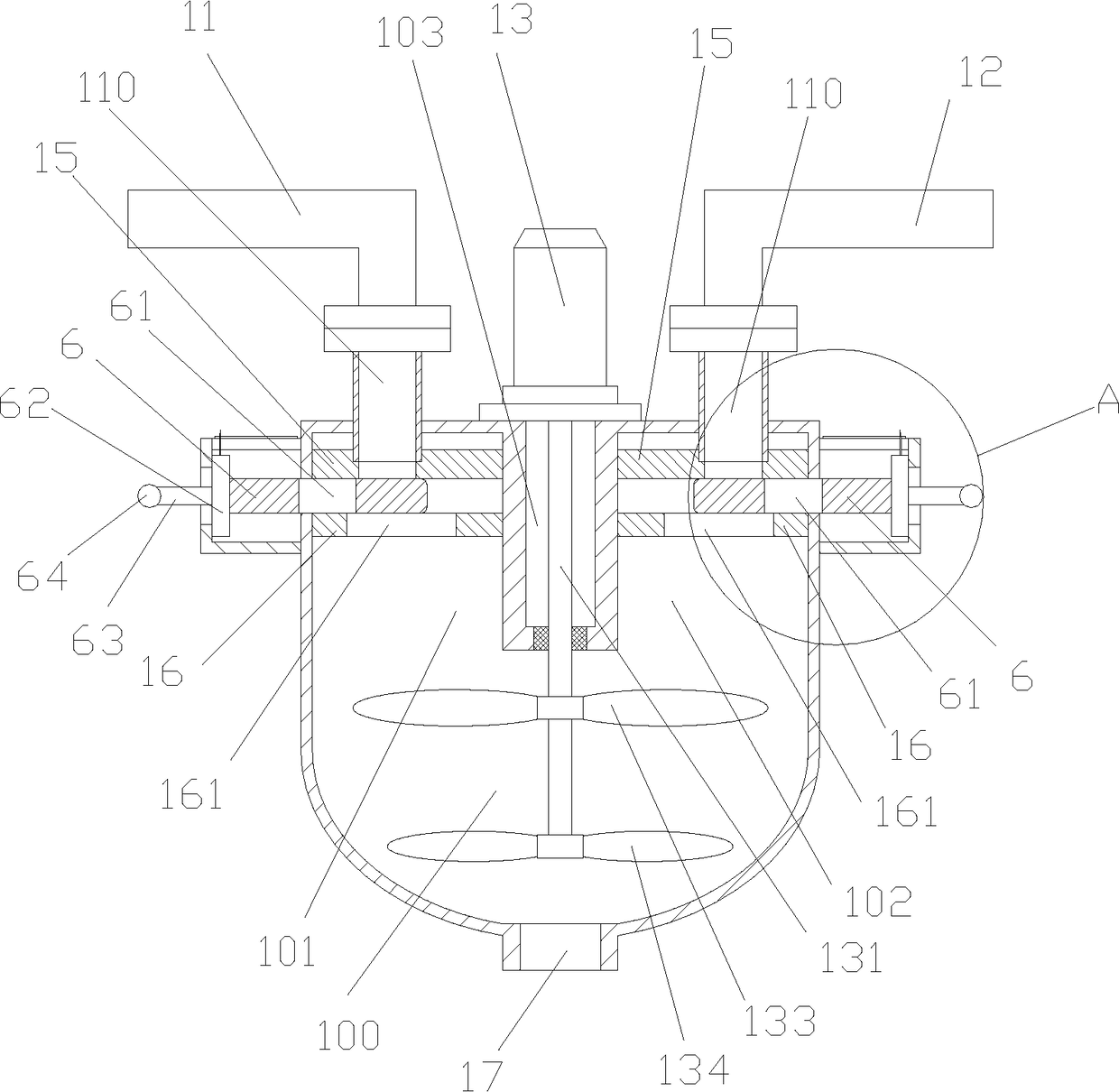

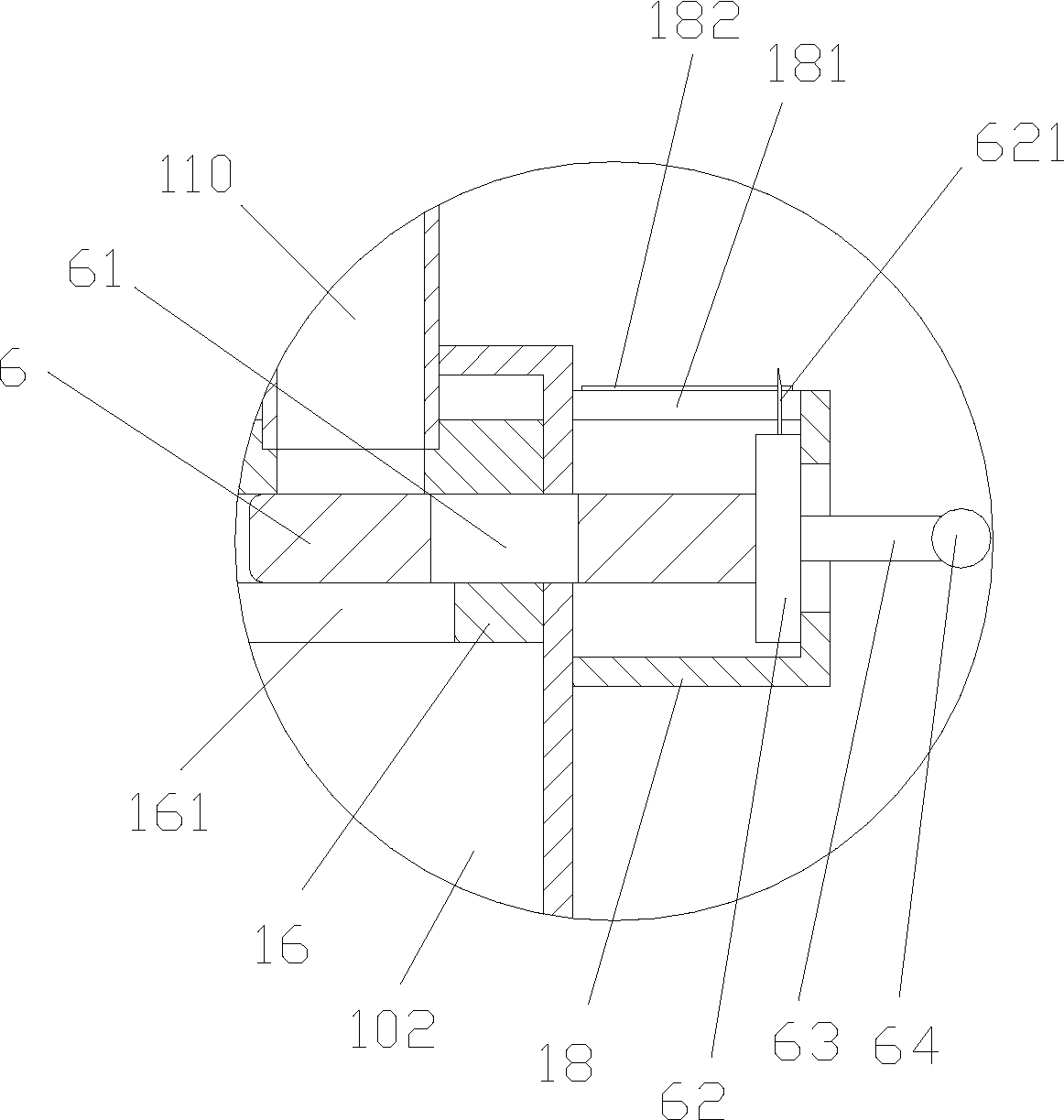

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1 to Figure 5As shown, an industrial wastewater treatment system includes a reaction tank 1, a sedimentation tank 2, a sediment bin 3 and a transport device 4; the reaction tank 1 is provided with a first liquid inlet chamber 101 and a second liquid inlet chamber 102, A mixing reaction chamber 100 is provided below the first liquid inlet chamber 101 and the second liquid inlet chamber 102, and the first liquid inlet chamber 101 and the second liquid inlet chamber 102 are separated by a motor chamber 103 A water inlet pipe 110 is respectively arranged above the first liquid inlet chamber 101 and the second liquid inlet chamber 102, and the diameter of the water inlet pipe 110 is square, and a sewage inlet pipe 11 and a sewage inlet pipe 11 are arranged above the reaction pool 1. Reactant inlet pipe 12, the sewage inlet pipe 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com