A 3D printing method

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of easy adhesion of liquid raw materials on the inner wall, increased cleaning time, waste of liquid raw materials, etc., to avoid local agglomeration, prevent solidification, and reduce residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

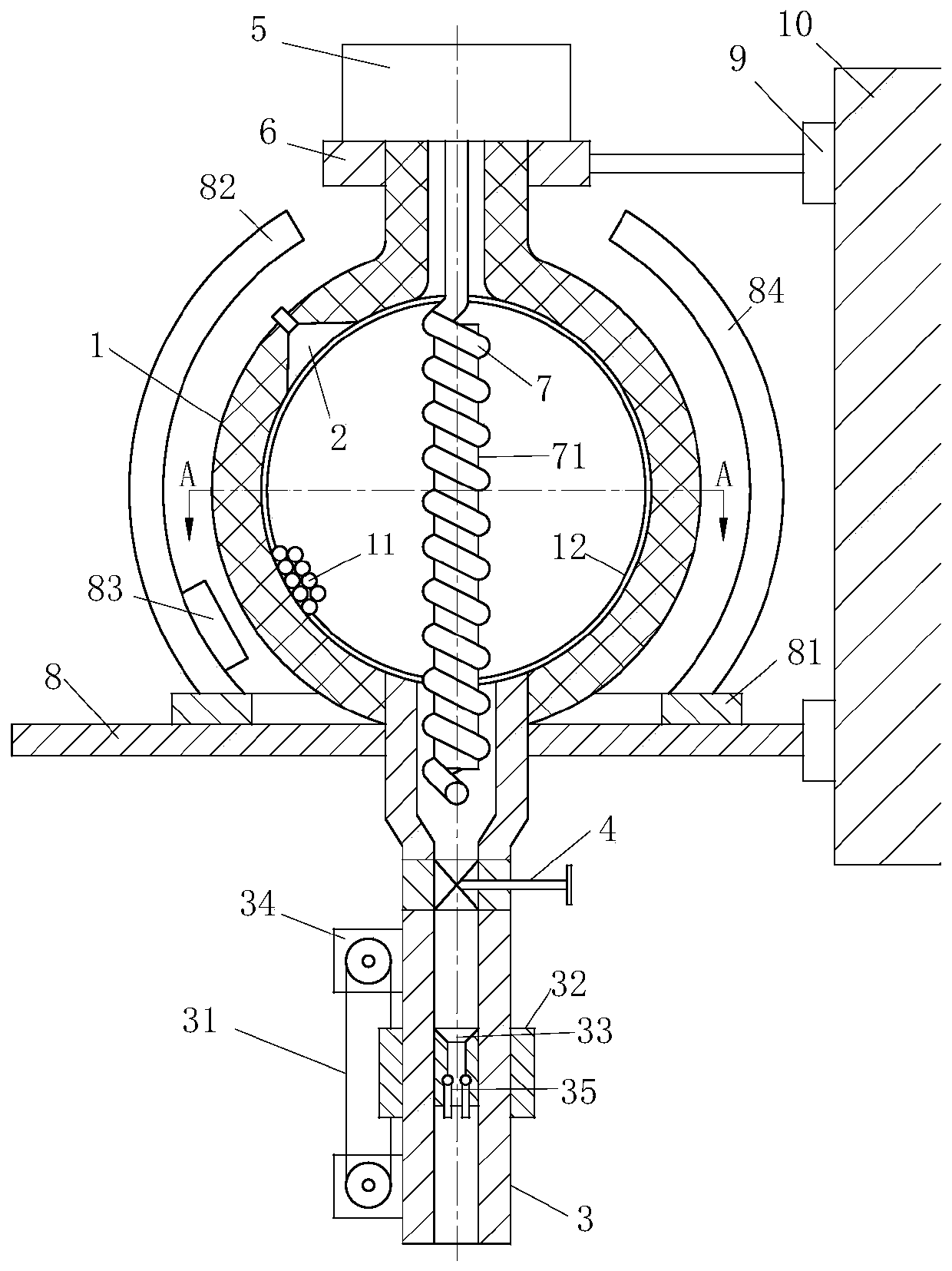

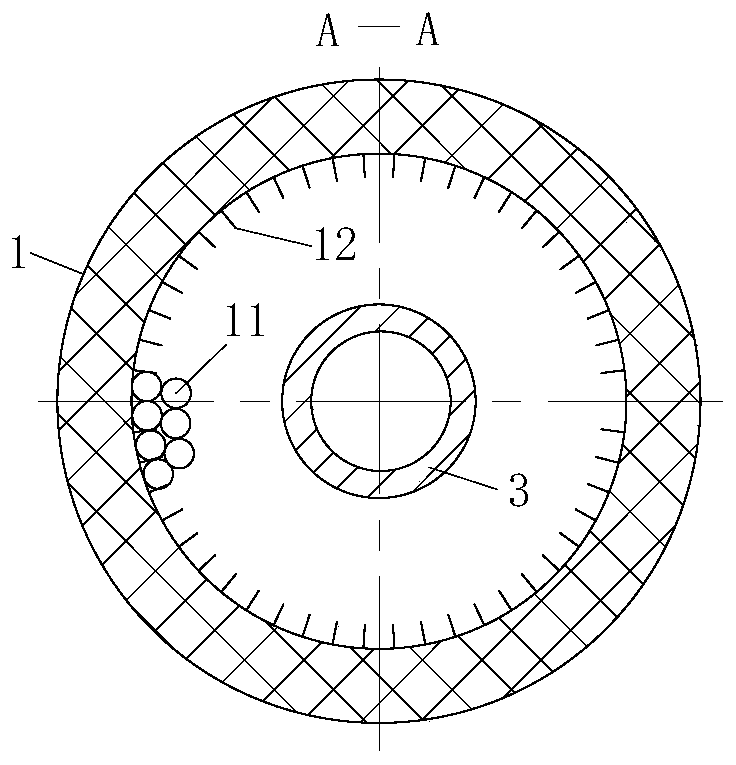

[0026] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

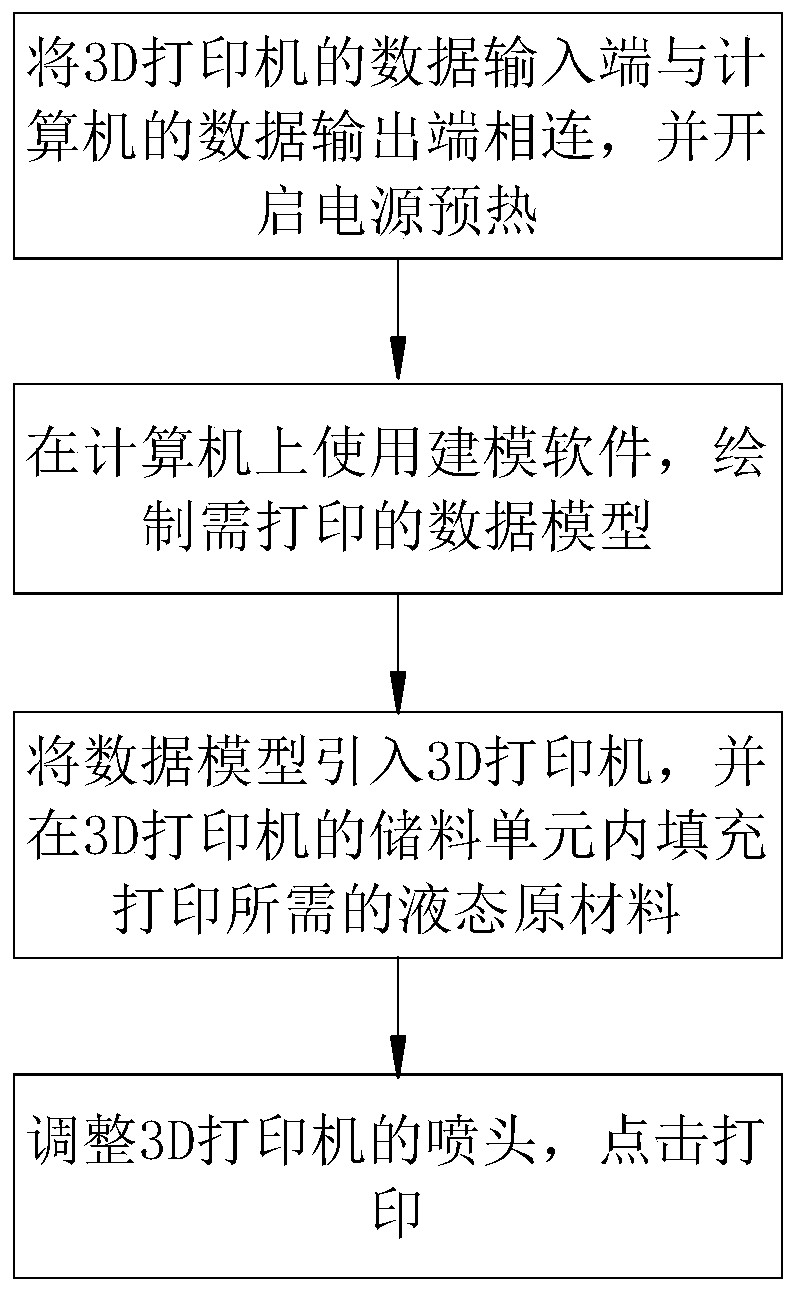

[0027] like Figure 1 to Figure 3 Shown, a kind of 3D printing method described in the present invention, this method adopts following steps:

[0028] Step 1: Connect the data input terminal of the 3D printer to the data output terminal of the computer, and turn on the power to preheat;

[0029] Step 2: Use modeling software on the computer in Step 1 to draw the data model to be printed;

[0030] Step 3: Introduce the data model drawn in Step 2 into the 3D printer through the data line, and fill the liquid raw material required for printing in the storage unit of the 3D printer;

[0031] Step 4: After filling the storage unit of the 3D printer in step 3, adjust the nozzle of the 3D printer and click Print;

[0032]The storage unit includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com