Plywood composite device

A composite device and plywood technology, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of large veneer workload, small thickness, and easy breakage of veneers, so as to reduce the workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

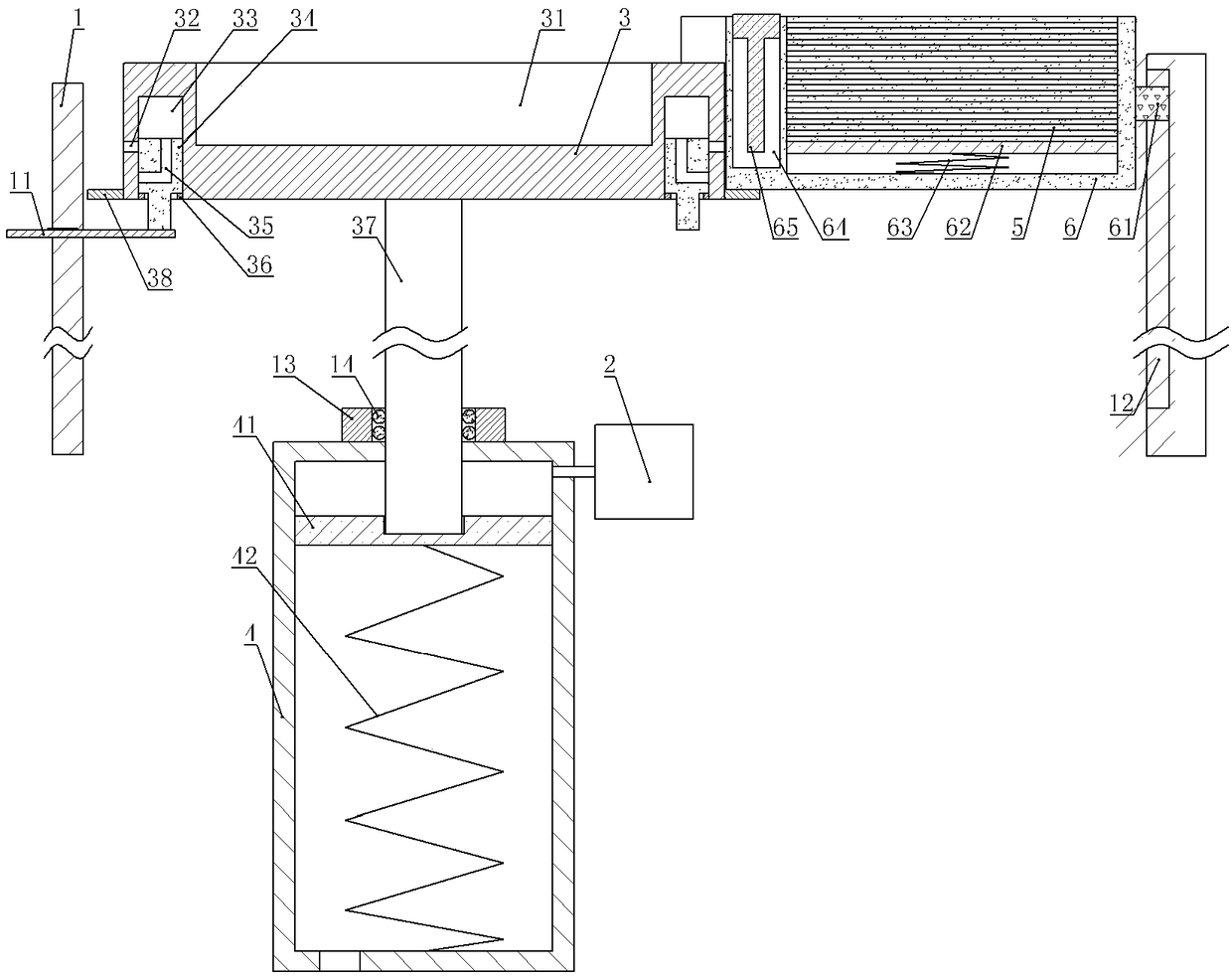

[0025] The reference signs in the drawings of the description include: frame 1, fixed plate 11, chute 12, threaded block 13, ball 14, air pump 2, workbench 3, compound groove 31, exhaust channel 32, exhaust groove 33, Closed block 34, L-shaped channel 35, limit block 36, threaded rod 37, support ring 38, cylinder 4, piston 41, return spring 42, veneer 5, storage box 6, slider 61, support plate 62, support Spring 63, glue tank 64, sponge block 65.

[0026] Plywood composite installations such as figure 1 As shown, it includes a frame 1, a compound mechanism and a material storage mechanism. The compound mechanism includes a workbench 3, a cylinder 4 and an air pump 2 that are all fixed on the frame 1 by bolts. The workbench 3 is cylindrical, and the center of the workbench 3 is Composite slot 31 is provided at; frame 1 is provided with four fixed passages from top to bottom, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com