Aluminum material production equipment

A kind of production equipment, aluminum technology, applied in the field of aluminum material production equipment, can solve the problems such as the inability to realize multiple sets of drilling operations, single setting mode, and reduce processing efficiency, so as to improve the drilling efficiency and drilling effect, and the device The structure is simple and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

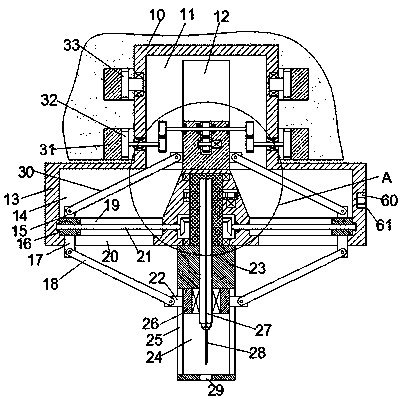

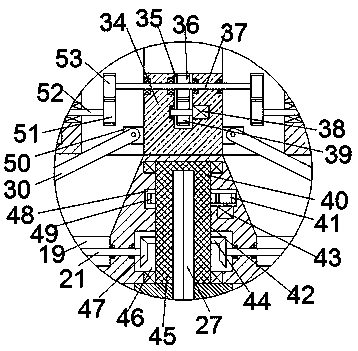

[0015] Such as Figure 1-2 As shown, an aluminum material production equipment of the present invention includes a sliding seat 10 arranged in a wall that can move back and forth through a driving device, a placement frame 13 integrally provided with the sliding seat 10, and a fixed installation The guide arm 23 at the bottom of the placement frame 13 is provided with a first sliding groove 24 extending up and down in the guide arm 23, and a first sliding block 26 is slidably installed in the first sliding groove 24, A spline shaft 27 extending up and down is installed in the first sliding block 26, and the left and right side walls of the first sliding groove 24 are symmetrically provided with a first communication groove 25 outside the communication. The end faces of the left and right sides of the moving block 26 are symmetrically provided with a first connecting block 22 protruding from the first communication groove 25, and a first turning groove 42 is arranged above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com