A New Spraying Machine with High Convenience for Automobiles

A technology of convenience and spraying machine, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems that the high-pressure hose cannot be stored firmly, the high-pressure hose cannot be stored in the spraying machine, and the work of the high-pressure hose is cumbersome. The work is smooth and smooth, reducing the jumping phenomenon and realizing the effect of winding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

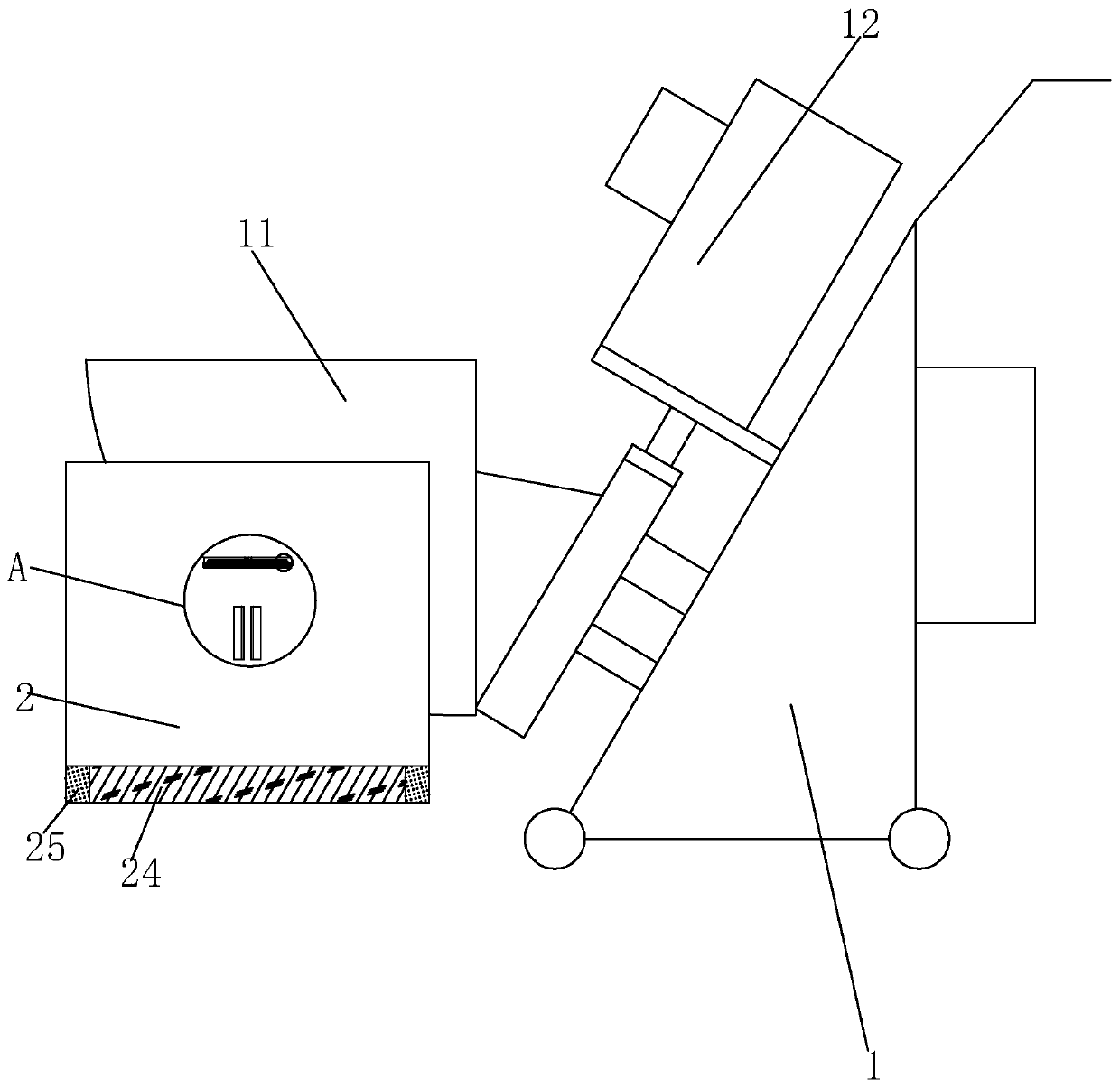

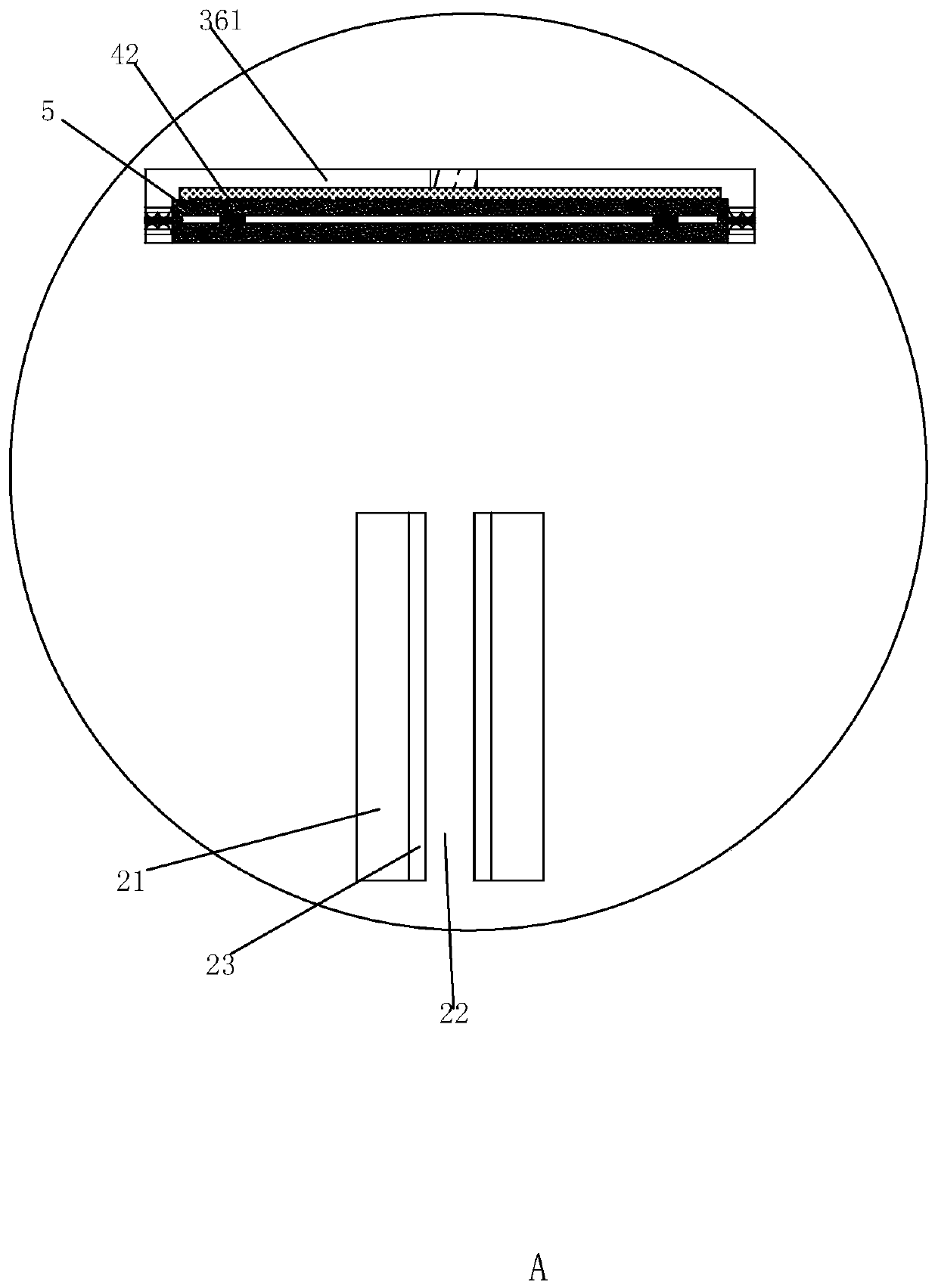

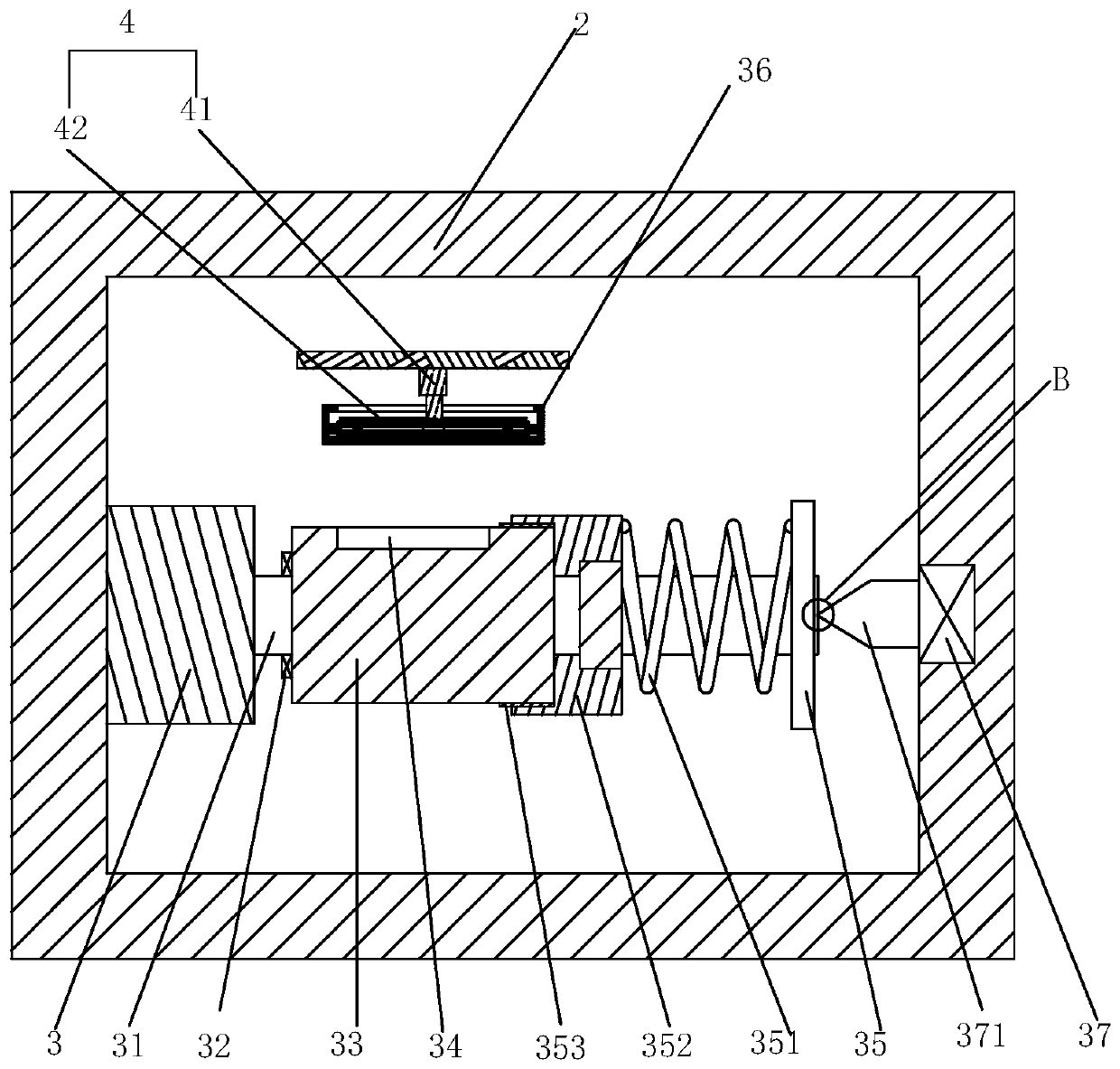

[0031] Embodiment 1: a kind of novel spraying machine with high convenience for automobile, such as figure 1 As shown, it includes a body 1, which is provided with a material storage frame 11 for paint storage and an air motor 12 that acts on the paint. The outlet of the material storage frame 11 is connected to a high-pressure water pipe 5 (not shown in the figure) ,Such as Figure 5 and 7 As shown, the cross-section of the high-pressure water pipe 5 is square, that is, the high-pressure water pipe 5 is in the shape of a flat mouth as a whole, and a plurality of guide grooves 51 are arrayed on the upper surface of the high-pressure water pipe 5 along its width direction.

[0032] Such as figure 1 and 3 As shown, on the body 1, the side wall of the material storage frame 11 can be fixed with a storage basket for water supply pipe storage, and the side wall in the storage basket is fixed with a drive motor 3, and the output shaft 31 of the drive motor 3 A first connecting b...

Embodiment 2

[0039] Embodiment 2: a novel spraying machine with high convenience for automobiles, the difference from embodiment 1 is that, as Figure 8 As shown, the two sides of the high-pressure water pipe 5 along its width direction are fixed with an extended braid 52, and the end of the extended braid 52 away from the high-pressure water pipe 5 is fixed with a metal sheet 53. At the same time, in the limit frame 36 Both ends of the limit notch 361 are provided with a limit notch 363 communicating with the limit notch 361 and for the metal sheet 53 to be embedded. Block 364, the connecting block 364 is provided with a guide wheel 365 that conflicts with the extended braided belt 52.

[0040] At the same time, if Figure 7 As shown, two rubber strips 54 are arranged in the high-pressure water pipe 5 along its width direction, and a rubber storage groove 55 for embedding the rubber strips 54 is arranged in the high-pressure water pipe 5 .

[0041] Specific implementation methods: the m...

Embodiment 3

[0043] Embodiment 3: a novel spraying machine with high convenience for automobiles, the difference from Embodiment 1 is that, as Figure 6 As shown, the upper and lower layers of the high-pressure water pipe 5 are respectively fixed with an upper iron sheet 56 and a lower iron sheet 57, and the limit frame 36 is fixedly provided with an electromagnet three 366 adsorbed to the lower iron sheet 57, and the bottom surface of the pressing plate 42 is fixed. Be provided with the electromagnet four 367 that upper iron sheet 56 is adsorbed, be provided with the pressure sensor 368 that is connected with miniature cylinder 41 circuit signals in the electromagnet four 367.

[0044] Since the high-pressure water pipe 5 is in a closed state during the winding process, the speed at which the paint enters the spray gun through the high-pressure water pipe 5 is limited in the process of spraying the car. When the high-pressure water pipe 5 is extracted, when the high-pressure water pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com