A paint processing mixing and stirring device

A technology of mixing and coating, applied in mixers, mixers, mixing methods and other directions with rotary stirring devices, can solve problems such as the decline in the use effect of coatings, waste of coating materials, and affect the quality of coatings, saving time and reducing costs. , the effect of improving the effect and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

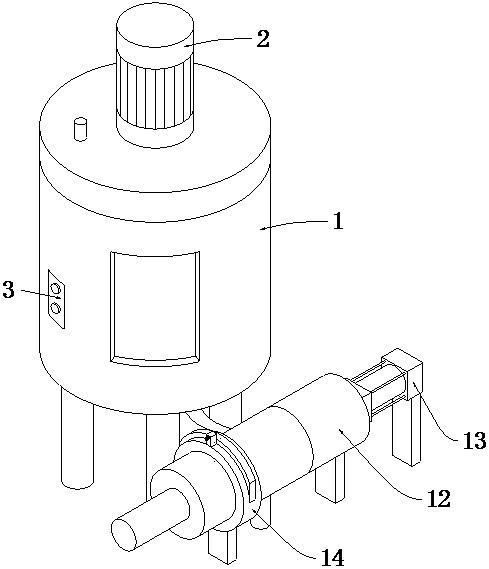

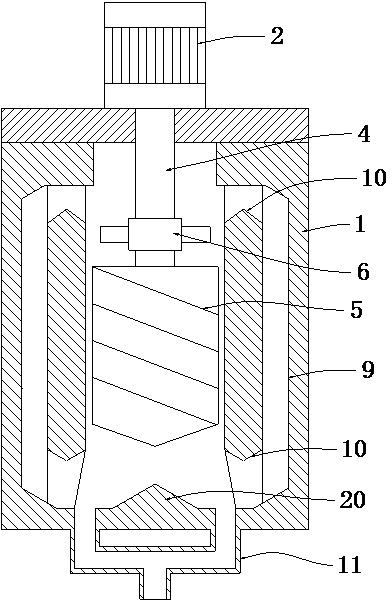

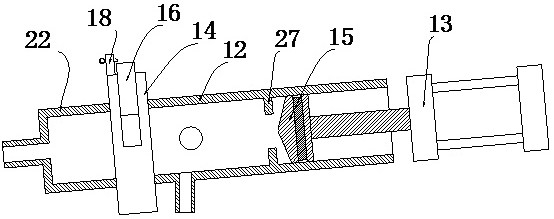

[0031] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 Shown, a kind of coating processing mixing stirring device of the present invention comprises tank body 1, also comprises:

[0032] The deceleration motor 2 placed on the top of the tank body 1, the surface of the tank body 1 is provided with a control switch 3, the end of the output shaft of the deceleration motor 2 is provided with a rotating shaft 4, the rotating shaft 4 is placed inside the tank body 1, and the rotating shaft 4 The end of the shaft is provided with a pusher stirring head 5, the middle part of the rotating shaft 4 is provided with a connecting block 6, and the outer side of the connecting block 6 is surrounded by a number of stirring blades 7, and the reduction motor 2 is electrically connected with the external power supply through the control switch 3. The reduction motor 2 can drive the rotating shaft 4 to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com