Absorption core body of ultrathin belt flow conducting groove

A technology of absorbing cores and diversion grooves, applied in the field of hygiene products, can solve the problems of easy clumping, lack of comfort, waste of raw materials, etc., and achieve the effects of blocking movement, increasing comfort, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

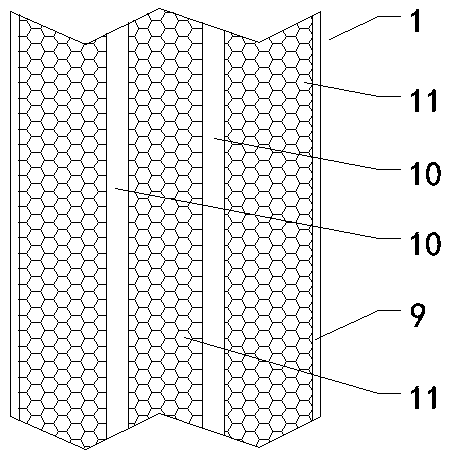

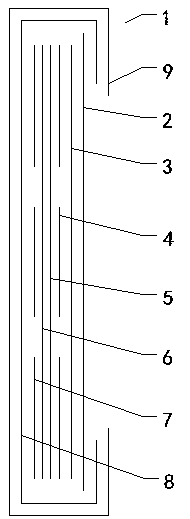

[0009] refer to Figure 1-Figure 2 , an ultra-thin absorbent core with diversion grooves, including a core body 1, the core body 1 is composed of an upper layer of non-woven fabric 2, a surface layer of squeegee rubber layer 3, and an upper layer of continuous or intermittent strip-shaped polymer water-absorbing material layer 4 , the first structural adhesive layer 5, the second structural adhesive layer 6, the lower layer of continuous or discontinuous strip polymer water-absorbing material layer 7, the lower layer of squeegee rubber layer 8, and the lower layer of non-woven fabric 9, the bottom of the upper layer of non-woven fabric 2 passes through the surface The scraping rubber layer 3 is bonded to the top of the upper continuous or intermittent strip-shaped polymer water-absorbing material layer 4, and the bottom of the upper continuous or intermittent strip-shaped polymer water-absorbing material layer 4 passes through the first structural adhesive layer 5 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com