Efficient preparing method and application of fenugreek absolute oil

A fenugreek and ultrasonic technology is applied in the application field of efficient preparation of fenugreek pure oil and cigarette flavoring, which can solve the problems of heat-not-burn cigarette smoking experience, high production cost, low net oil yield and the like, and achieves improvement. Effects of richness and aftertaste, production cost reduction, yield and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

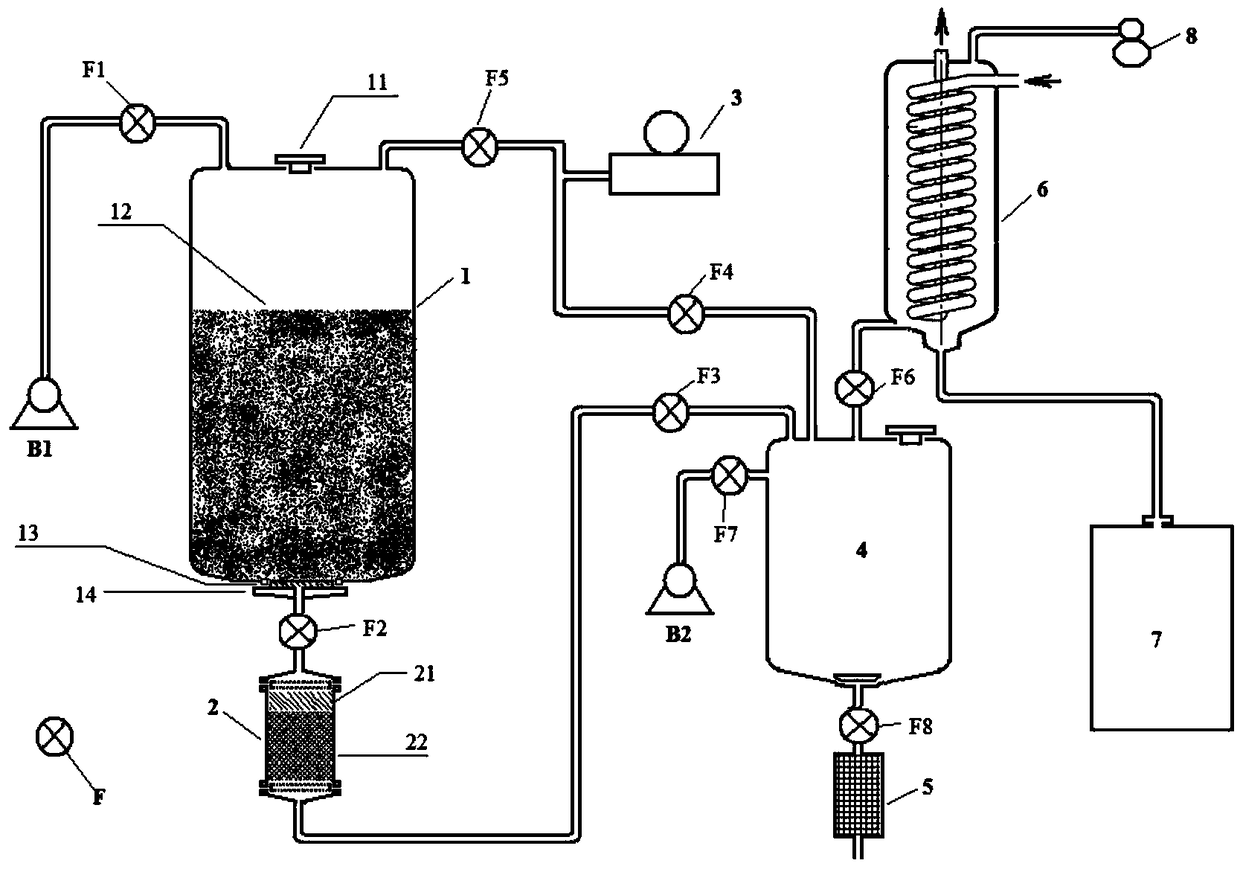

[0068] The raw material is extracted from mature seeds of fenugreek. The sample is roasted and crushed to 20 meshes. The feeding amount is 200 kg. It is added to the ultrasonic extraction tank 1, the feeding port and the discharge port are sealed, and methyl acetate 5 times the weight of the fenugreek sample is added. Esters were ultrasonically extracted at 45°C for 35 minutes. After the extraction, the air compressor was started to pressurize the ultrasonic extraction tank, and the extract was allowed to pass through the filter sieve plate at the outlet and lead to the chromatographic column for purification.

[0069] After the extract passed through the chromatographic column was transferred to the concentration tank, the temperature of the concentration tank was raised to 80° C., and at the same time, the vacuum pump was started to concentrate the extract until the methyl acetate was evaporated to dryness. Return the methyl acetate recovered after the sample concentration to...

Embodiment 2

[0072]The fenugreek absolute oil prepared by the above method is used in cigarette shreds, the fenugreek absolute oil is added to the shredded tobacco at a ratio of 5 / 100,000 of the weight of the shredded tobacco, and the shredded tobacco is made into finished cigarettes for evaluation and smoking. The results show that the fenugreek absolute oil prepared by the present invention can effectively endow cigarettes with a maple syrup-like caramel-sweet aroma and nutty aroma, improve the aroma quantity and aroma quality of cigarette smoking, and can also cover up the miscellaneous gases of cigarette smoking , improving the comfort of cigarette smoking, which is better than that of the control sample (that is, the cigarette without adding the fenugreek absolute oil obtained by the present invention). or,

[0073] In the cigarette filter molding process, the fenugreek absolute oil obtained in the present invention is added to triacetin by 1 wt% of the amount of plasticizer triacetin...

Embodiment 3

[0076] During the preparation process of the electronic cigarette liquid, the fenugreek absolute oil of the present invention is added to the fenugreek-flavored electronic cigarette liquid in a proportion of 5% by weight. The results show that: the total score of the fenugreek absolute oil of the present invention is relatively high, and its advantages are mainly manifested in the characteristics of charred sweetness similar to maple syrup and the characteristics of nutty kernels, good aroma quality, and sufficient aroma; secondly, it is light in miscellaneous odors, The aftertaste is cleaner and better than that of the control sample (that is, the electronic cigarette without adding the fenugreek absolute oil obtained by the present invention).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com