Grading type shelling and separating integrated machine for camellia oleifera fresh fruits based on multiple channels

A multi-channel, hierarchical technology, applied in the fields of shelling, food processing, pod removal, etc., can solve the problems of high loss of camellia oleifera seeds, unsatisfactory cleaning effect of camellia oleifera husks and tea seeds, and low removal rate of fresh camellia oleifera fruits , to achieve good cleaning effect and realize the effect of integrated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

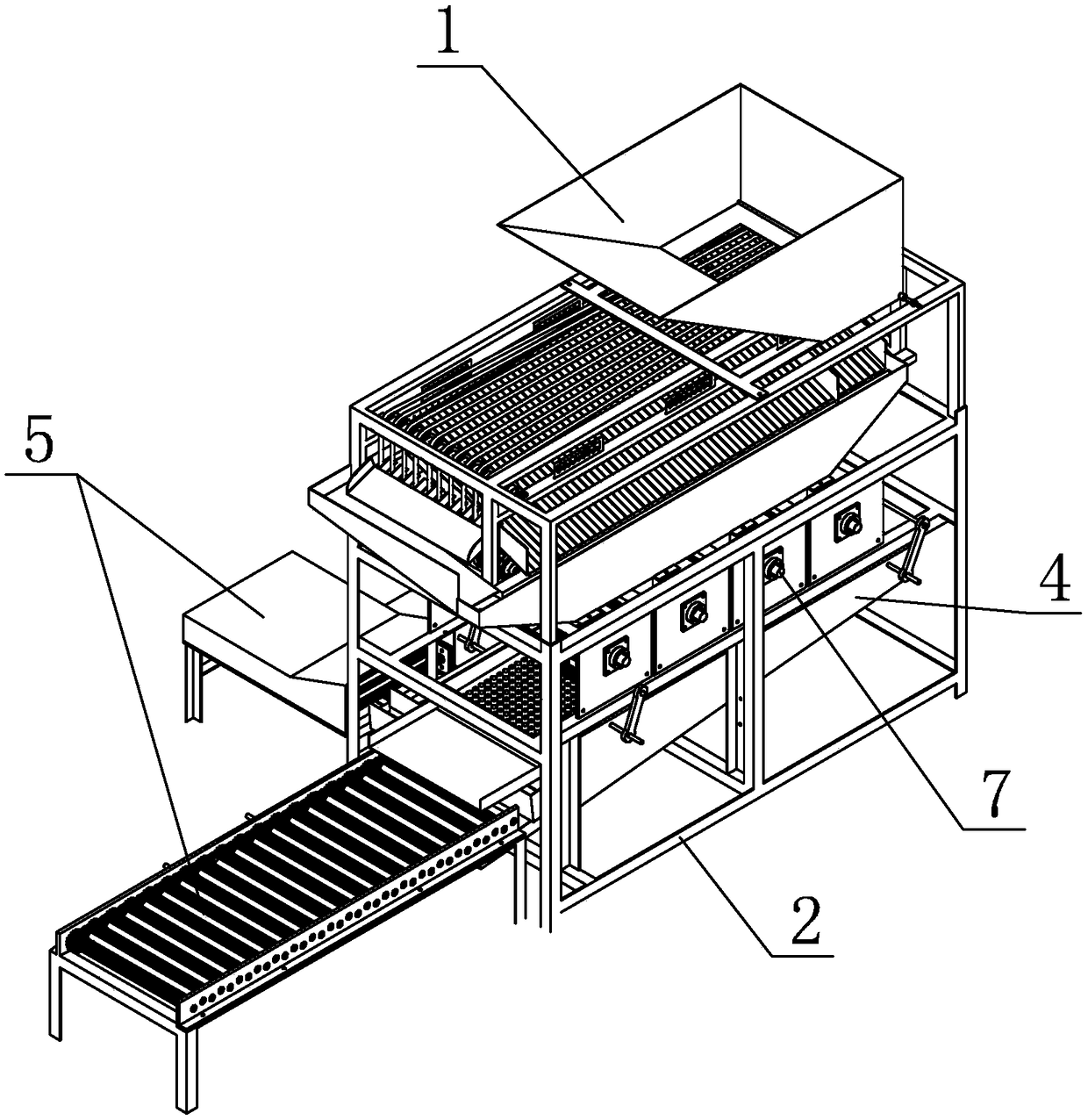

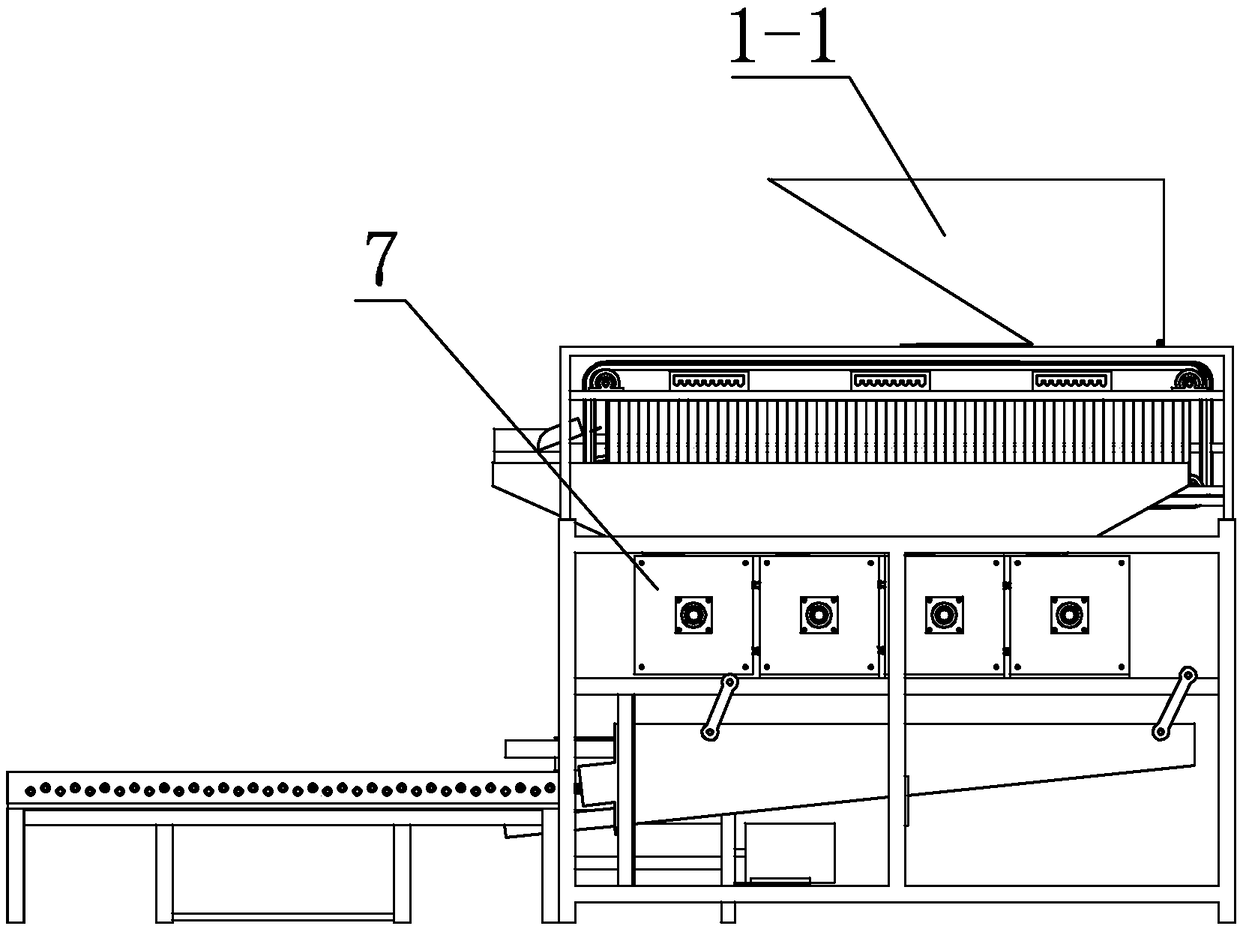

[0027] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 8 To illustrate this embodiment, this embodiment includes a multi-channel sorting mechanism 1, a frame 2, a transmission mechanism 3, a vibration screening mechanism 4, two sets of seed shell separation mechanisms 5, multiple hoppers 6 and multiple shelling devices 7;

[0028] A plurality of hoppers 6 are fixed on the frame 2, and each shelling device 7 fixed on the frame 2 is arranged below each hopper 6, and the top of each hopper 6 is connected with the sorting out of the multi-channel sorting mechanism 1. Corresponding to the feed port, each shelling device 7 is driven by the transmission mechanism 3, and the first discharge port is arranged below each shelling device 7, and each discharge port is arranged on the top of the vibrating screening mechanism 4, and the vibrating screening mechanism 4 is provided with two discharge ports, and each discharge port of the v...

specific Embodiment approach 2

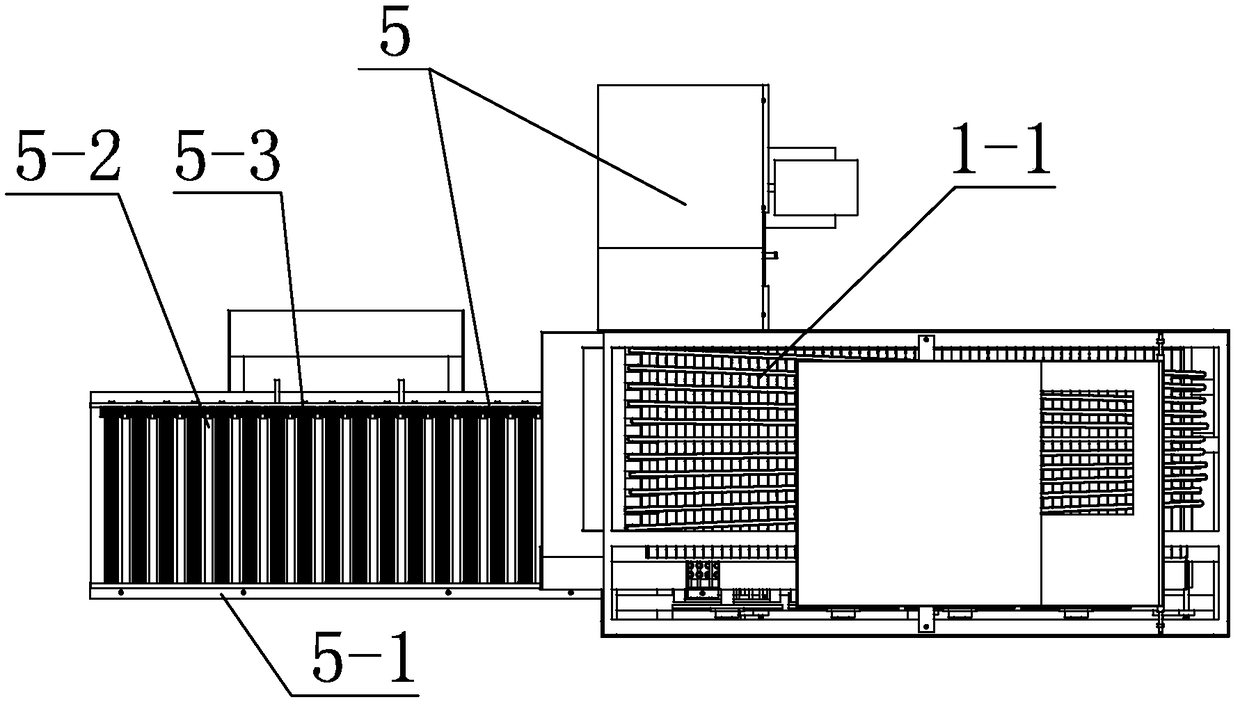

[0029] Specific implementation mode two: combination figure 1 , image 3 with Figure 14 To illustrate this embodiment, each set of seed shell separation mechanism 5 in this embodiment includes a frame body 5-1, a plurality of small shaft rollers 5-2 and a plurality of large shaft rollers 5-3;

[0030] Each small-axis roller 5-2 and each large-axis roller 5-3 are equidistantly arranged side by side on the frame body 5-1, and a large-axis roller 5-3 is arranged between two adjacent small-axis rollers 5-2 , a certain distance is provided between each large shaft roll 5-3 and each small shaft roll 5-2 and can only accommodate Camellia oleifera husks to pass through, and each small shaft roll 5-2 is connected with each large shaft roll 5-2. One end of 3 is driven by a pair of gears meshing with each other, and the other end of one of the small shaft rollers 5-2 or the other end of one of the large shaft rollers 5-3 is driven by a motor.

[0031] In this embodiment, a plurality ...

specific Embodiment approach 3

[0035] Specific implementation mode three: combination figure 1 ,with Figure 9 with Figure 10 To illustrate this embodiment, each shelling device 7 described in this embodiment includes an orifice 7-1, a shelling shaft 7-2 and a plurality of shelling rods 7-3, and a plurality of shelling rods 7-3 are fixedly connected On the shelling shaft 7-2, the shelling shaft 7-2 is arranged on the frame 2, the orifice plate 7-1 is arranged below the shelling shaft 7-2, and the hole of each shelling device 7 The holes on the plate 7-1 can accommodate the camellia oleifera seeds to pass through.

[0036] In this embodiment, the holes of the orifice 7-1 of each shelling device 7 match the volume of the sorted Camellia oleifera, avoiding the shelling of Camellia oleifera with different volumes in a sheller, and the camellia oleifera with large seeds Be stuck in the hole plate 7-1 and be broken by shelling bar 7-3 problem.

[0037] Other compositions and connections are the same as those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com