Defect detection method and detection device of mobile phone shell

A technology of mobile phone casing and detection method, which is applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of easy misjudgment, inaccuracy, low detection efficiency, etc. , the detection range is wide, the effect of high intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

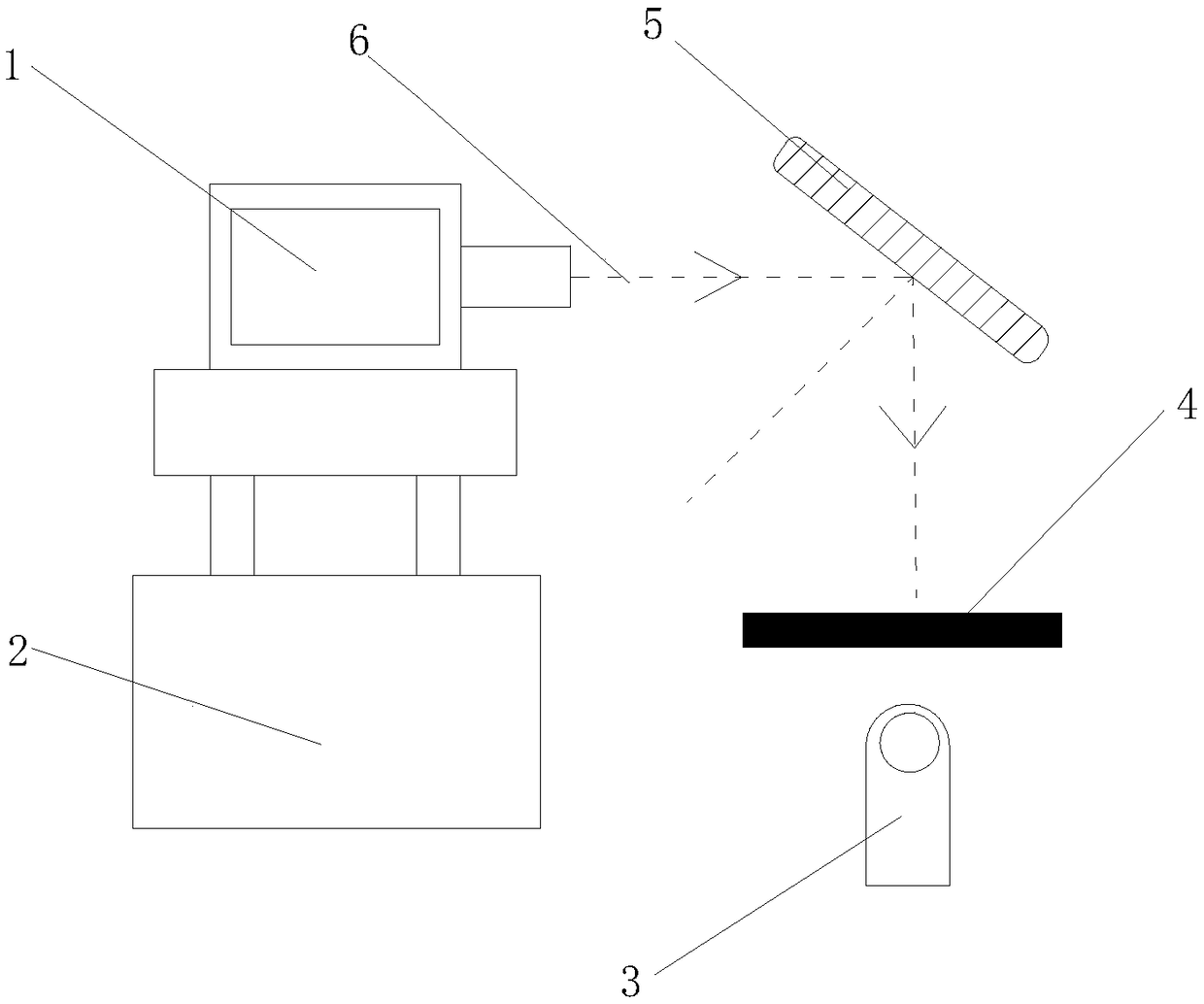

[0018] Such as figure 1 The detection method and detection device for the defects of the mobile phone shell shown include a laser transmitter 1, a motion module 2, a camera 3, and an optical filter 4, and the laser transmitter 1 is arranged on the motion module 2, and the The laser emitter 1 is used to provide a laser source for detecting the mobile phone casing 5, the optical filter 4 is arranged along the light path direction of the reflection angle of the mobile phone casing 5, and the camera 3 is arranged below the optical filter 4.

[0019] Said laser emitter 1 emits a horizontal laser light source directly onto the surface of the mobile phone casing 5 after being filtered, and the light finally enters the shooting area of the camera 3 after being reflected by the mobile phone casing 5 .

[0020] The wavelength emitted by the laser transmitter 1 is 350-450nm.

[0021] The incident angle between the light emitted by the laser transmitter 1 and the glass screen 5 ranges ...

Embodiment 2

[0026] Such as figure 1 The detection method and detection device for glass screen defects shown include a laser transmitter 1, a motion module 2, a camera 3, and an optical filter 4. The laser transmitter 1 is arranged on the motion module 2, and the The laser transmitter 1 is used to provide a laser source for detecting the glass screen 5 , the optical filter 4 is arranged along the optical path direction of the reflection angle of the glass screen 5 , and a camera 3 is arranged below the optical filter 4 .

[0027] The laser emitter 1 emits a horizontal laser light source directly onto the surface of the glass screen 5 , the light passes through the filter 4 after being reflected by the glass screen 5 , and the light through the filter 4 finally enters the shooting area of the camera 3 .

[0028] The wavelength emitted by the laser transmitter 1 is 400nm.

[0029] The incident angle range of the light emitted by the laser emitter 1 and the glass screen 5 is 50°.

[0030...

Embodiment 3

[0034] Such as figure 1 The detection method and detection device for glass screen defects shown include a laser transmitter 1, a motion module 2, a camera 3, and an optical filter 4. The laser transmitter 1 is arranged on the motion module 2, and the The laser transmitter 1 is used to provide a laser source for detecting the glass screen 5 , the optical filter 4 is arranged along the optical path direction of the reflection angle of the glass screen 5 , and a camera 3 is arranged below the optical filter 4 .

[0035] The laser emitter 1 emits a horizontal laser light source directly onto the surface of the glass screen 5 , the light passes through the filter 4 after being reflected by the glass screen 5 , and the light through the filter 4 finally enters the shooting area of the camera 3 .

[0036] The wavelength emitted by the laser transmitter 1 is 450nm.

[0037] The incident angle range of the light emitted by the laser emitter 1 and the glass screen 5 is 80°.

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Angle of incidence | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com