A kind of culture method of iron oxidation leaching microorganism

A technology of ore leaching microorganisms and culture methods, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem that iron-containing sulfate ions cannot be discharged directly, the cell concentration does not increase significantly, and the delay of ore leaching microorganisms is shortened period and other problems, to achieve the effect of easy solid-liquid separation, shorten the culture time, and reduce the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

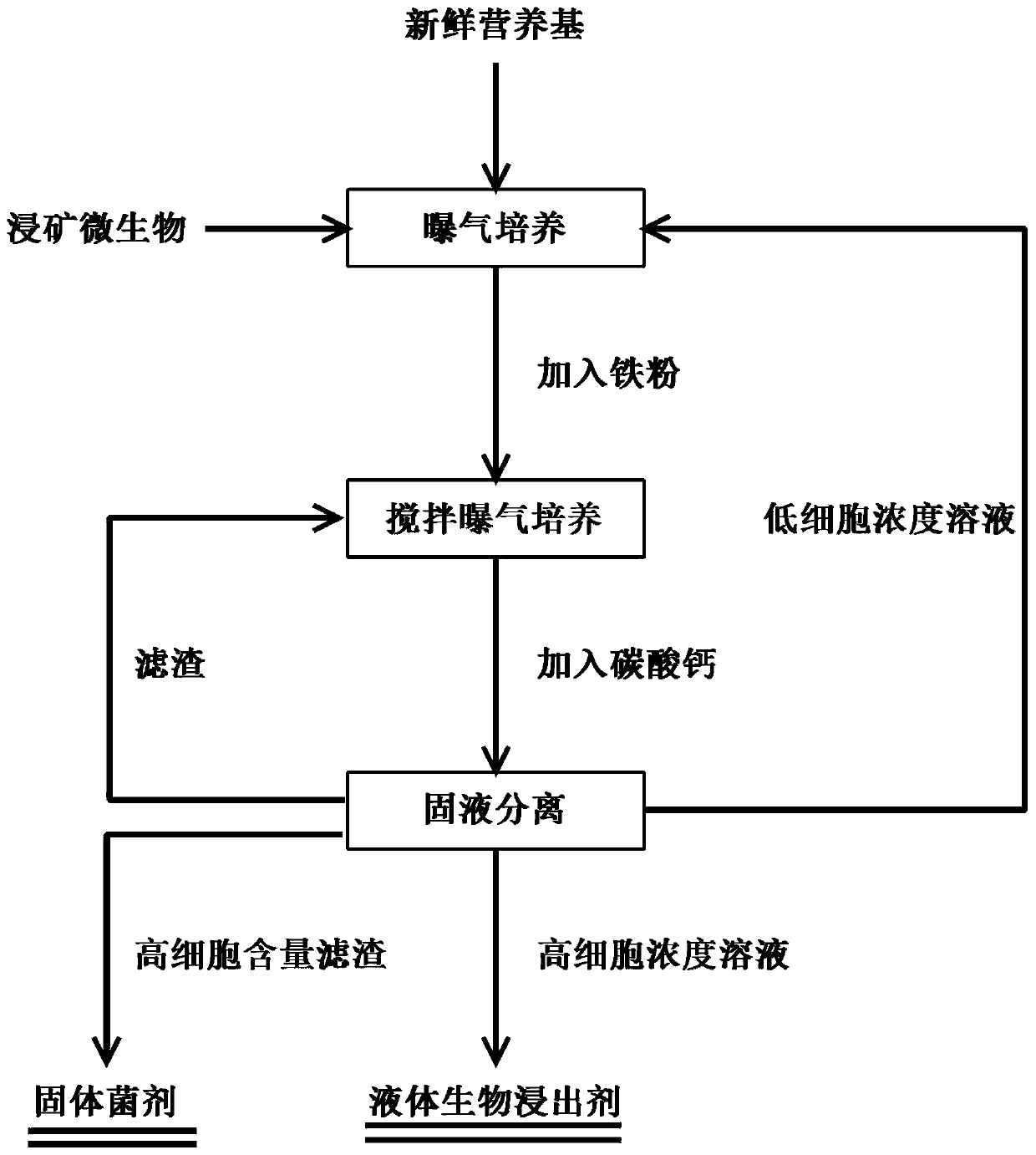

Method used

Image

Examples

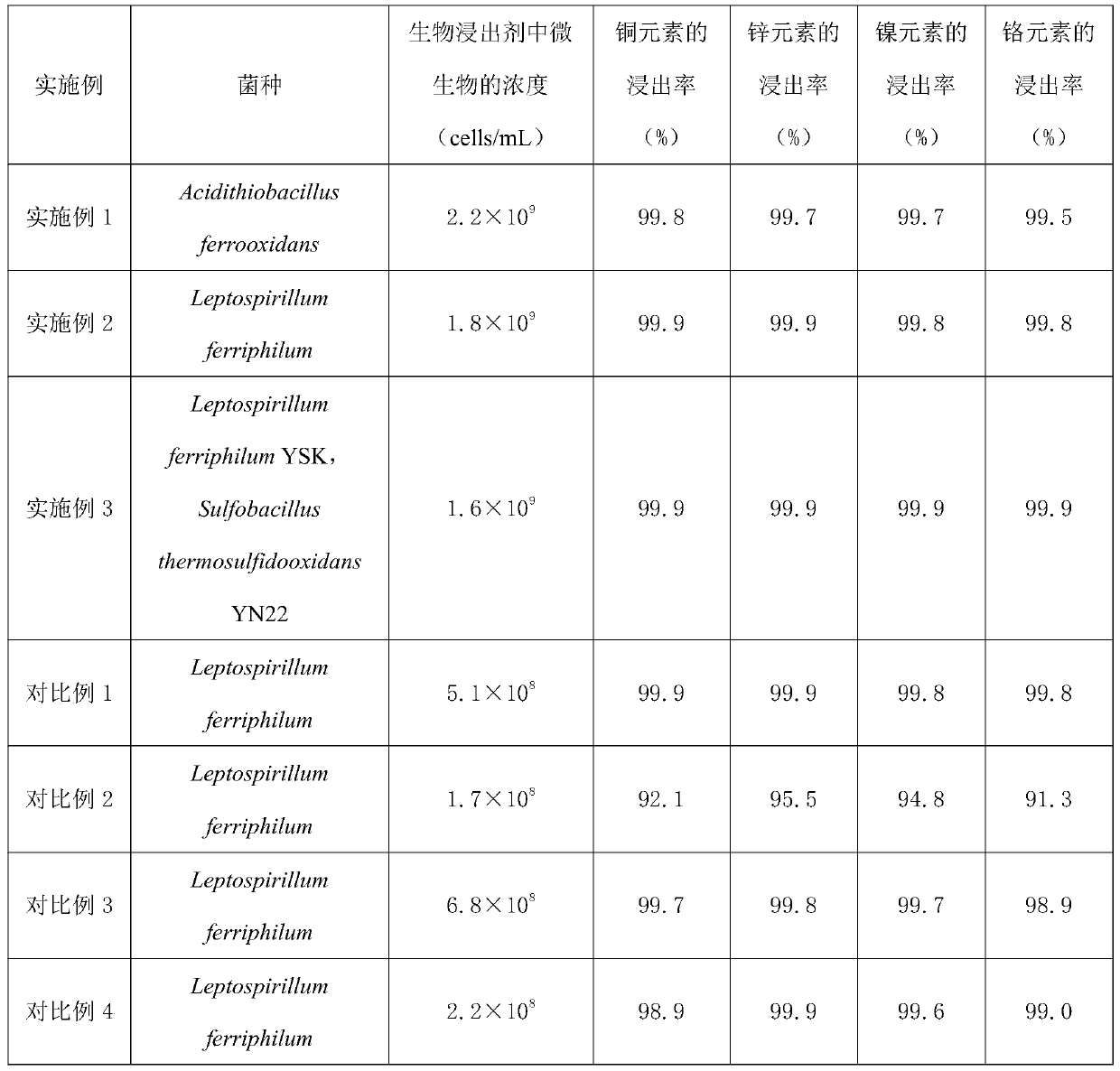

Embodiment 1

[0045] 1) Cultivate Acidithiobacillus ferrooxidans in a 5L aeration packing tank, the medium is a standard 9K medium, pH 1.8, the temperature is controlled at 30°C, microporous aeration is used, the aeration rate is 0.3vvm, the initial The microbial concentration is 1.2×10 7 cells / mL, cultured for 48 hours, the microbial concentration reached 1×10 8 cells / mL, oxidation-reduction potential 671mV, transfer the culture solution to a 5L conical-bottom stirred culture tank, stir, and add 30g of iron powder with a particle size of 200 mesh. After the iron powder is completely dissolved, the total iron ion concentration does not exceed 20g / mV L, then add sulfuric acid solution to adjust the pH to 1.8, continue to stir and aerate for 8 hours, the stirring speed is 60rpm, and the aeration rate is 0.3vvm;

[0046] 2) When adding sulfuric acid solution in step 1), when the oxidation-reduction potential of the culture solution after aerated culture is 650-716mV, transfer the culture solu...

Embodiment 2

[0050] 1) Cultivate active Leptospirillum ferriphilum in a 300L aerated packing tank, the medium is a standard 9K medium, the initial ferrous ion concentration is 9g / L, and the initial microbial concentration is 1.5×10 7 cells / mL, pH value 1.5, controlled temperature 45°C, microporous aeration, aeration rate 0.3vvm, cultured for 48 hours, the microbial concentration reached 2.4×10 8 cells / mL, oxidation-reduction potential 705mV, transfer the culture solution to a 300L conical bottom stirring culture tank, stir, and add 2.7Kg of iron powder with a particle size of 200 mesh, after the iron powder is completely dissolved, the total iron ion concentration should not exceed 20g / L, then add sulfuric acid solution to adjust the pH to 1.0, continue to stir and aerate for 7 hours, the stirring speed is 120rpm, and the aeration rate is 0.1vvm;

[0051] 2) When adding sulfuric acid solution in step 1), when the oxidation-reduction potential of the culture solution after aerated culture ...

Embodiment 3

[0055] 1) Cultivate the mixed bacteria of Leptospirillum ferriphilumYSK and Sulfobacillus thermosulfidooxidansYN22 in a 1000L aerated packing tank, the medium is standard 9K medium, and the initial ferrous ion concentration is 9g / L, add yeast 0.005%, initial microbial concentration 2×10 7 cells / mL, pH value 1.5, controlled temperature 45°C, microporous aeration, aeration rate 0.3vvm, cultured for 60 hours, the microbial concentration reached 2.4×108 cells / mL, oxidation-reduction potential 675mV, transfer the culture solution to a 1000L conical bottom stirring culture tank, stir, and add 11Kg of iron powder with a particle size of 200 mesh, after the iron powder is completely dissolved, the total iron ion concentration does not exceed 20g / L, then add sulfuric acid solution to adjust the pH to 2.0, continue to stir and aerate for 8 hours, the stirring speed is 120rpm, and the aeration rate is 0.1vvm;

[0056] 2) When adding sulfuric acid solution in step 1), when the oxidation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com