A kind of graphene modified emulsion, its preparation method and application

A graphene modification and graphene dispersion technology, applied in the field of emulsions, can solve problems such as waste of petroleum resources, easy leakage of mineral oil, easy environmental pollution, etc., and achieve the effects of reducing shedding, improving cooling effect, and excellent thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, the volume fraction of the emulsion is 100 parts, and the formulation of the emulsion is as follows:

[0035] 2.8 parts of mineral oil, 0.2 parts of graphene oxide dispersion, 93 parts of deionized, 1.5 parts of polysorbate-80, 1.5 parts of benzotriazole, and 1 part of sodium benzoate.

[0036] Wherein, the graphene oxide dispersion is a water-based dispersion with a concentration of 1 mg / ml.

[0037] The preparation method of the emulsion is: according to the formula, adding mineral oil and deionized water into the container, then adding polysorbate-80 and stirring for 2 hours, then adding the graphene oxide dispersion, continuing to stir for 2 hours, and finally After adding benzotriazole and sodium benzoate and stirring for 1 hour, a graphene-modified emulsion can be obtained.

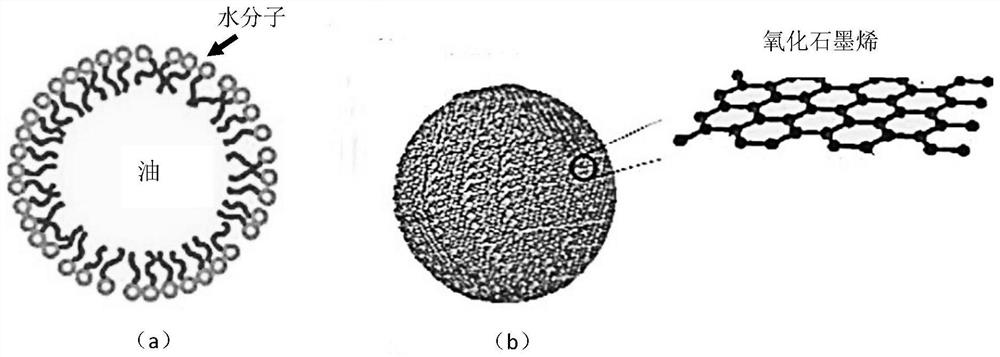

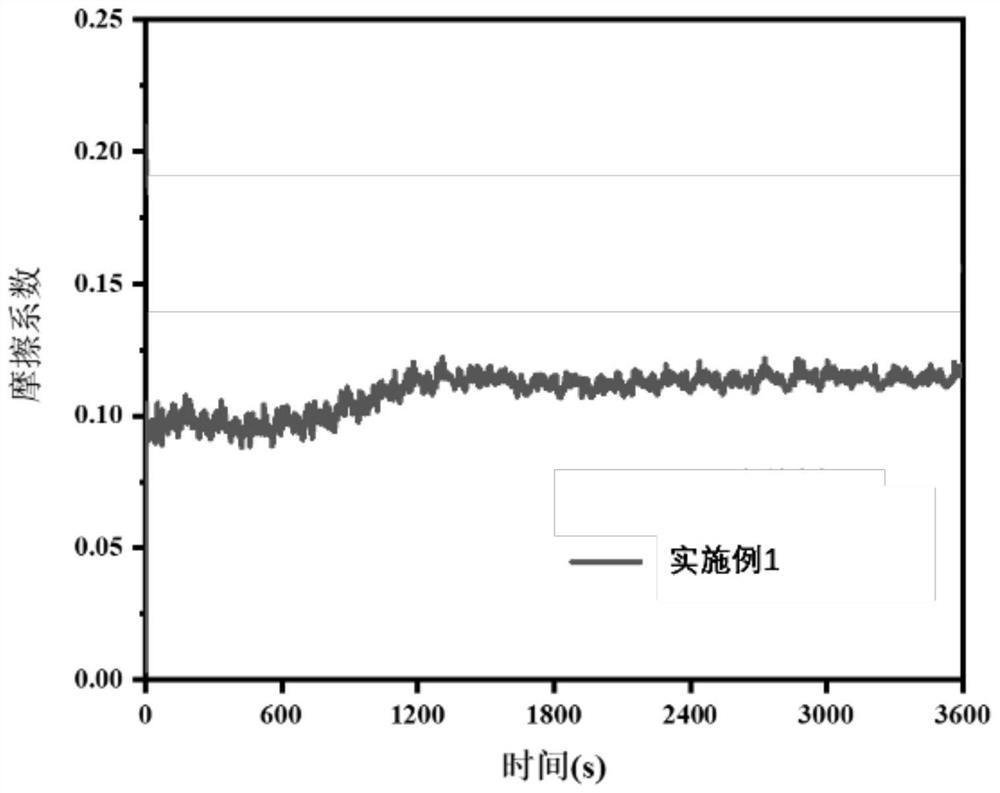

[0038] The appearance of the above-mentioned graphene-modified emulsion obtained is as follows: figure 2 As shown, the emulsion is uniform without precipitated i...

Embodiment 2

[0041] In the present embodiment, the volume fraction of the emulsion is 100 parts, and the formulation of the emulsion is as follows:

[0042] 4.1 parts of mineral oil, 0.4 parts of graphene oxide dispersion, 90 parts of deionized, 1.5 parts of polysorbate-80, 1.9 parts of benzotriazole, and 2.1 parts of sodium benzoate.

[0043] Wherein, the graphene oxide dispersion is a water-based dispersion with a concentration of 0.5 mg / ml.

[0044] The preparation method of the emulsion is as follows: according to the formula, put mineral oil and deionized water into the container, add polysorbate-80 and stir for 2 hours, then add graphene oxide dispersion, continue stirring for 2 hours, then add After stirring the benzotriazole and sodium benzoate for 1 hour, a graphene-modified emulsion can be obtained.

[0045] The graphene-modified emulsion obtained above has a similar appearance figure 2 As shown, it shows that the emulsion is uniform without precipitated impurities, and the co...

Embodiment 3

[0048] In the present embodiment, the volume fraction of the emulsion is 100 parts, and the formulation of the emulsion is as follows:

[0049] 3.2 parts of mineral oil, 0.3 parts of graphene oxide dispersion, 92 parts of deionized, 1.6 parts of polysorbate-80, 1.7 parts of benzotriazole, and 1.2 parts of potassium sorbate.

[0050] Wherein, the graphene oxide dispersion is a water-based dispersion with a concentration of 0.8 mg / ml.

[0051] The preparation method of the emulsion is as follows: according to the formula, put mineral oil and deionized water into a container, add polysorbate-80 and stir at 25°C for 2 hours, then add graphene oxide dispersion, and continue stirring for 2 hours. After adding benzotriazole and sodium benzoate and stirring for 1 hour, the graphene-modified emulsion can be obtained.

[0052] The graphene-modified emulsion obtained above has a similar appearance figure 2 As shown, it shows that the emulsion is uniform without precipitated impurities...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com