A polyethylene plastic film laser slitting component

A technology of plastic film and polyethylene, used in thin material processing, sending objects, transportation and packaging, etc., can solve problems such as poor cutting edge shape accuracy, affecting laser motion accuracy, reducing film quality, etc., to prevent transmission and improve cutting. effect, the effect of ensuring the transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

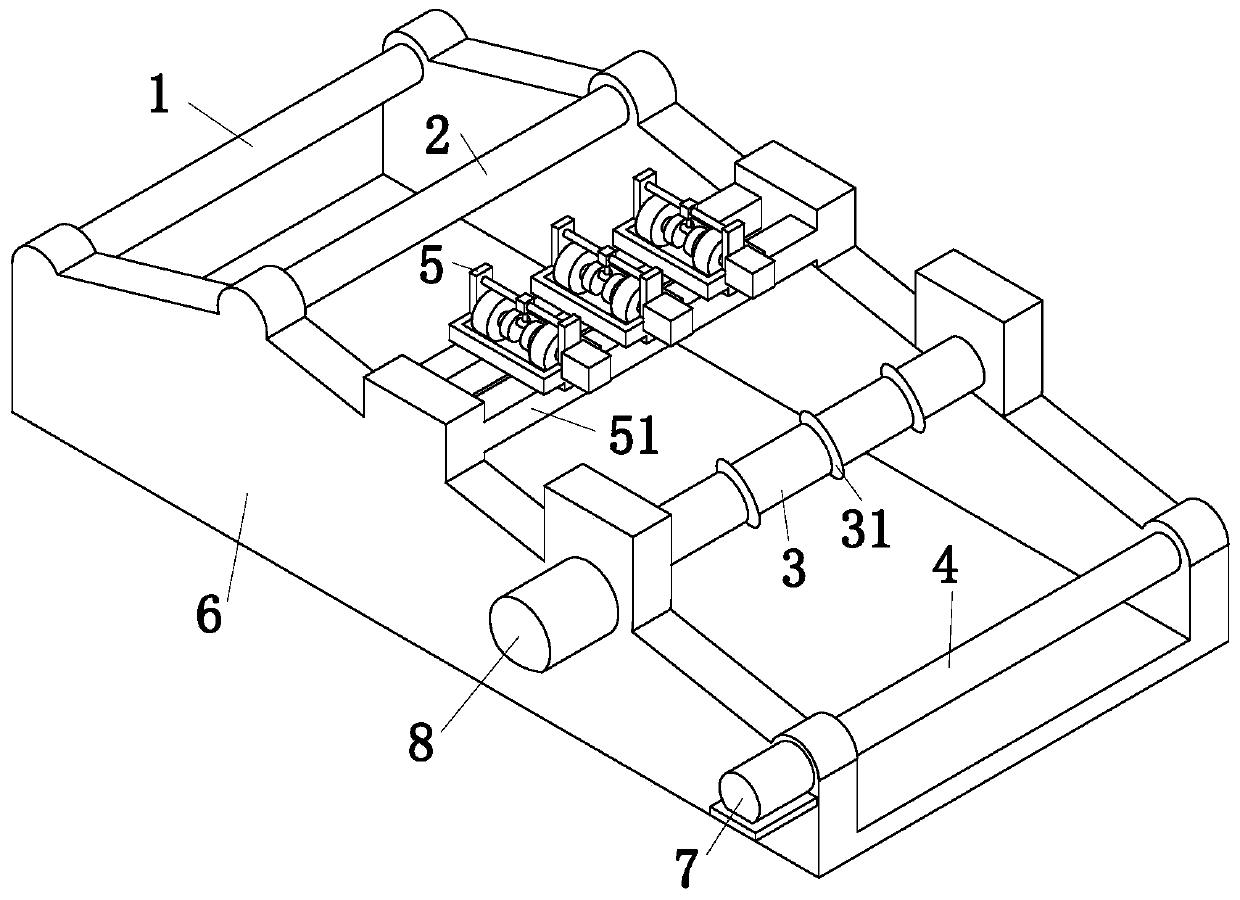

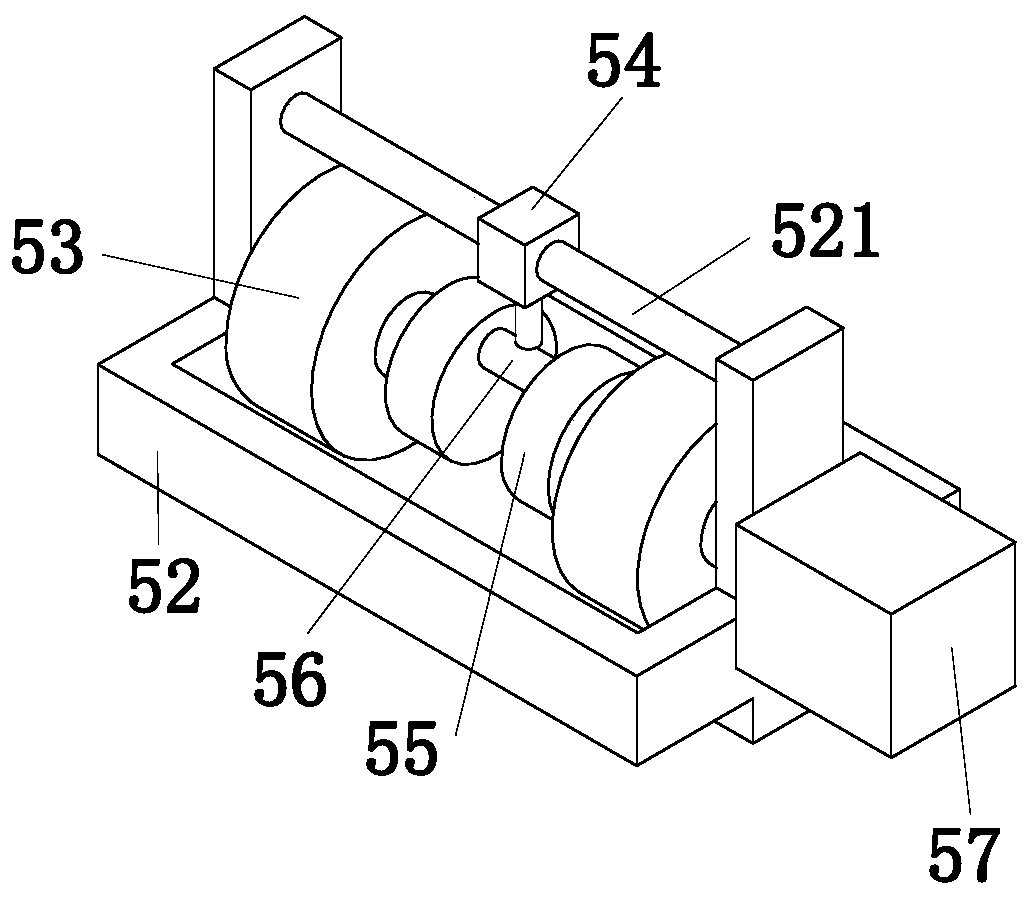

[0017] use figure 1 and figure 2 A polyethylene plastic film laser slitting assembly according to an embodiment of the present invention is described as follows.

[0018] Such as figure 1 and figure 2 As shown, a polyethylene plastic film laser slitting assembly according to the present invention includes a raw material roll 1, a drive roll 2, a separation rod 3, a winding roll 4, a cutting device 5 and a frame 6, and the raw material roll 1 Located at the front end of the frame 6; the drive roller 2 is located on the right side of the raw material roll 1; the cutting device 5 is located at the top left of the separation rod 3, and the number of cutting devices 5 is at least two, and the cutting device 5 can cut polyethylene plastic The film is cut into multiple pieces; the separation rod 3 is located on the right side of the drive roller 2, and the separation rod 3 is used to separate the cut polyethylene plastic film for subsequent winding; the winding roller 4 is locat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com