Chemical liquid raw material small packing barrel

A technology for chemical liquid and small packaging, applied in the field of small packaging barrels for chemical liquid raw materials, can solve the problems of leakage, quality degradation and splashing when the filling tube is inserted into the bottle mouth, and achieves the effect of promoting popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

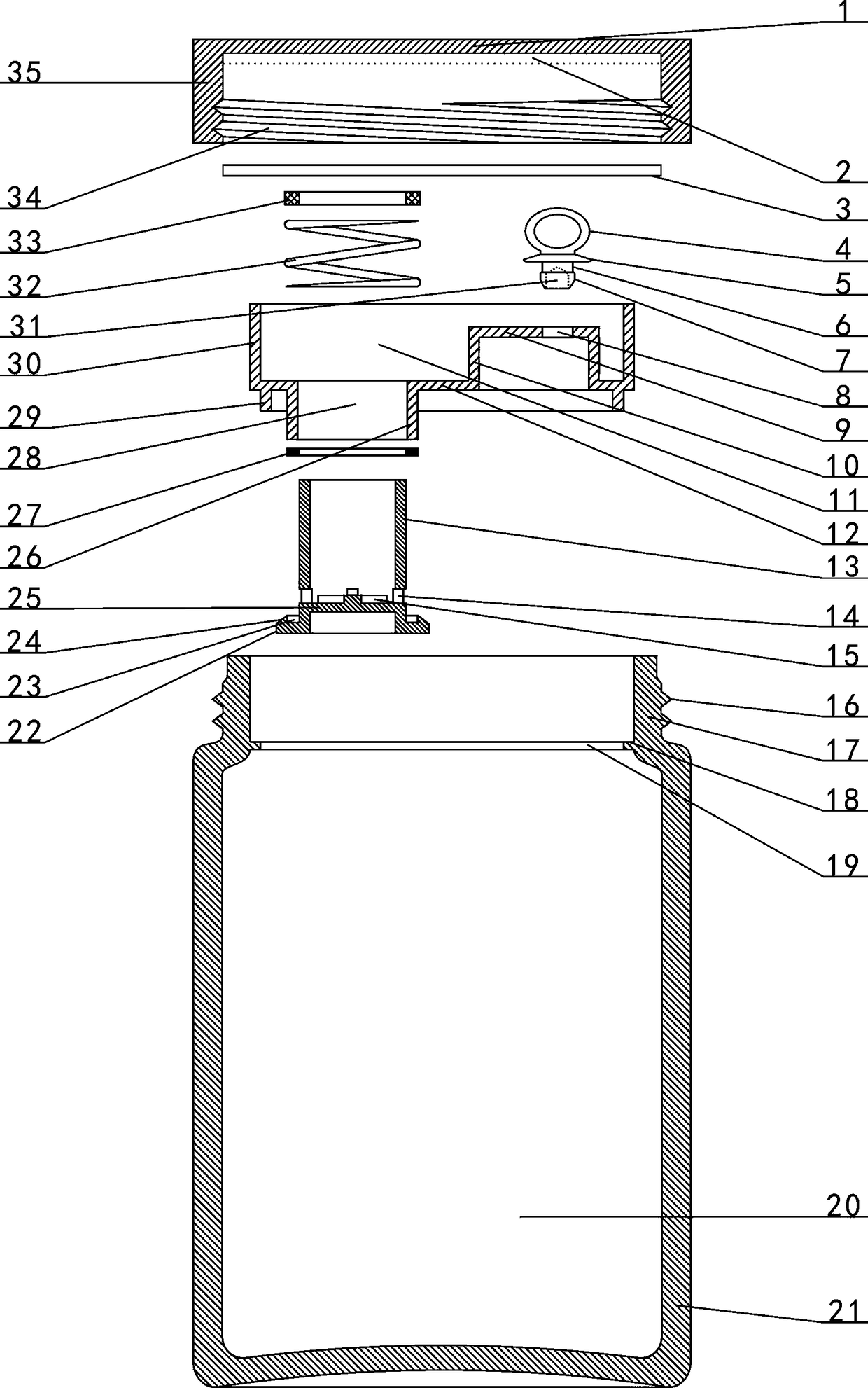

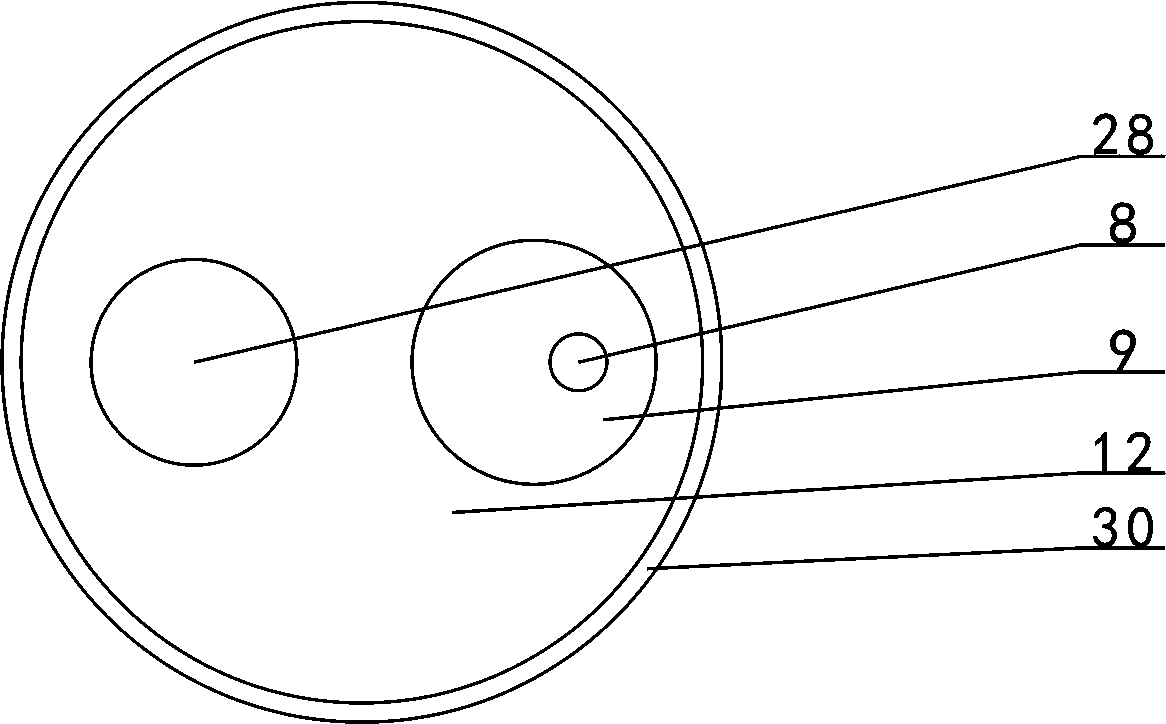

[0026] combined with Figure 1-7 The chemical liquid raw material small packaging barrel described in includes a bottle body 21, an upper cover 35, an inner cover, a spring 32, a lifting cylinder 13 and a sealing sheet 5, and an external thread is provided on the outer edge surface of the bottle mouth 17 of the bottle body 21. 16. The inner wall of the lower opening of the upper cover 35 is provided with an internal thread 34, and the lower part of the upper plate 1 of the upper cover 35 is provided with a sealing gasket 3, and the external thread 16 of the bottle mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com