Automatic Brick Separator for Brick Packing

A separator and brick technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of low efficiency and increase labor costs, and achieve the effect of simple pushing method and high pushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

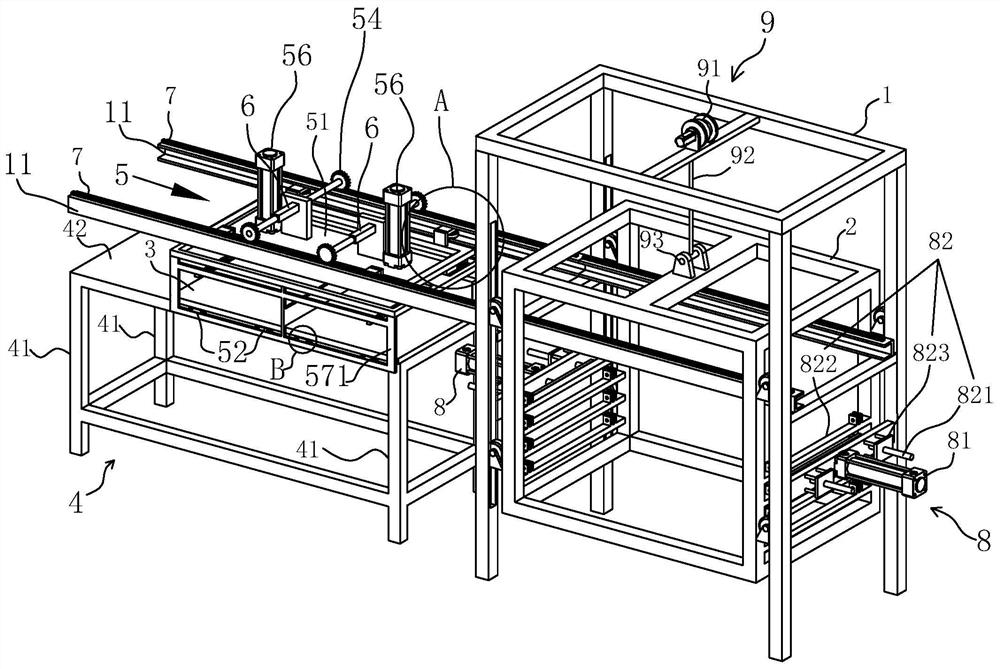

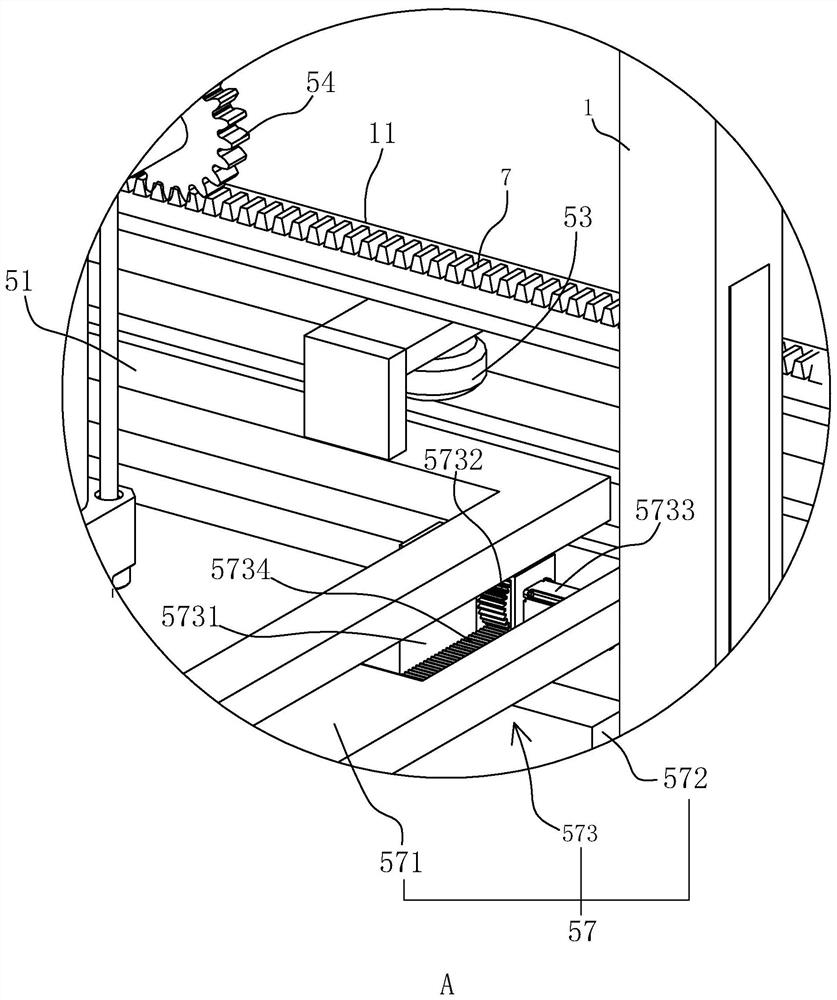

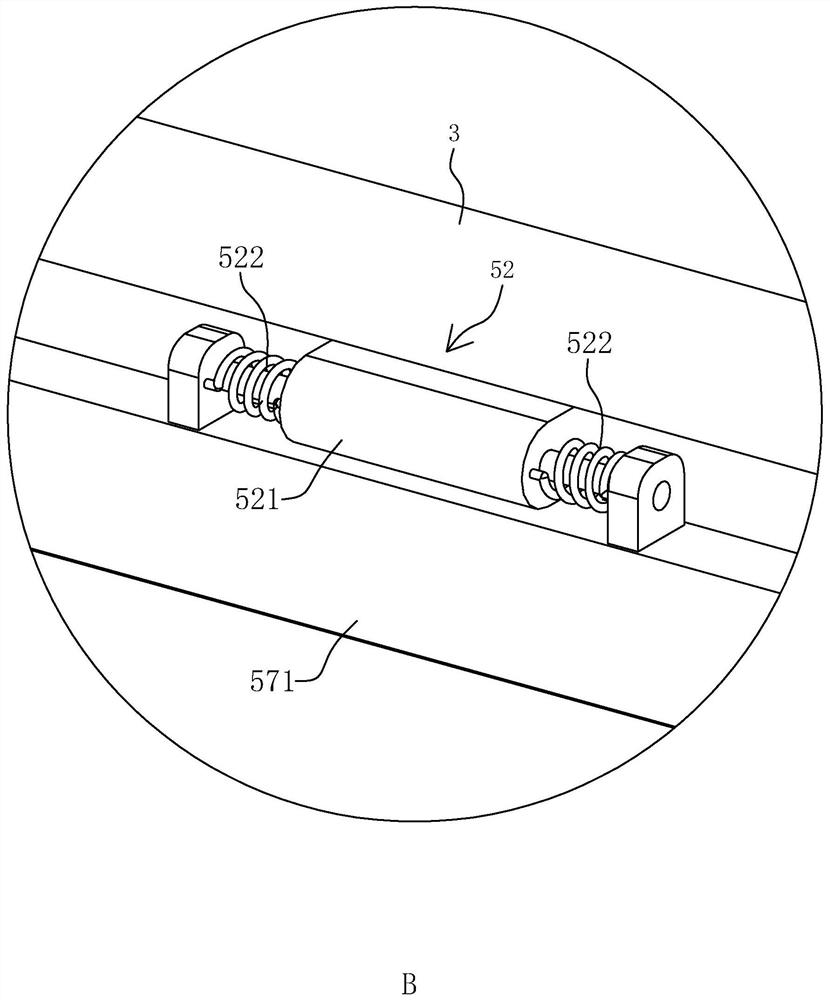

[0069] An automatic brick-slab separator for brick packing, combined with figure 1 and figure 2 As shown, it includes: a frame 1 , an inner frame 2 , a pallet 3 , a table 4 , a pushing component 5 , a power component 6 , a first rack 7 , an extruding component 8 and a lifting component 9 .

[0070] The frame 1 is placed horizontally on the ground, and the opposite inner sides of the frame 1 are respectively provided with horizontally arranged guide rails 11, a part of the guide rails 11 extends to the outside of the frame 1, and the inside of the frame 1 is also provided with a vertical track; The inner frame 2 is arranged inside the frame 1 and is slidably assembled with the vertical track of the frame 1. The inner frame 2 is used to store multi-layer pallets 3. A plurality of bricks are placed on the end face to form a brick array; the table 4 is located on one side of the frame 1 and is located below the part of the guide rail 11 protruding from the outside of the frame 1...

specific Embodiment 2

[0086] An automatic brick-slab separator for brick packing, combined with Figure 4 and Figure 5 As shown, the difference from the first embodiment is that the driving structure 573 includes: a slider 5735 , a screw 5736 and a first servo motor 5737 . The slider 5735 is fixedly assembled with the brick pushing plate 572 and is slidably mounted on the mounting frame 571; the screw rod 5736 is threadedly assembled with the slider 5735, and the screw rod 5736 is rotated and mounted on the mounting frame 571; the first servo motor 5737 is mounted on the screw rod 5736 one end. When the brick pushing plate 572 is aligned with the brick on the pallet 3, start the first servo motor 5737, and then drive the screw 5736 to rotate so as to drive the slider 5735 and the brick pushing plate 572 to move together to push the brick away from the pallet 3 For this purpose, the driving structure 573 is simple and easy to operate.

specific Embodiment 3

[0088] An automatic brick-slab separator for brick packing, combined with figure 1 and Figure 6 As shown, the difference from the first embodiment is that the automatic brick separator for brick packaging also includes: a collection box 12 and a conveying assembly 10 . The collection box 12 is arranged on one side of the table 4 and is used to collect the card boards 3; the transmission component 10 is arranged on the table 4 and pushes the card boards 3 into the collection box 12 one by one, and starts the transmission component located on the table 4 10. The pallets 3 are transferred to the collection box 12 one by one by the friction force between the pallet 3 and the transmission assembly 10, and the above process is repeated until the collection tank 12 is full of the pallets 3, and then the next collection box 12 is replaced to continue collecting Card board 3.

[0089] The transmission assembly 10 includes: a driving source 101 , a driving wheel 102 , a driven wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com