New anti-rolling torsion bar system and its positioning and installation method

An anti-roll torsion bar and system installation technology, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, can solve the problems of installation and disassembly, gaps in the positioning of support components and torsion bar components, and large arcs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

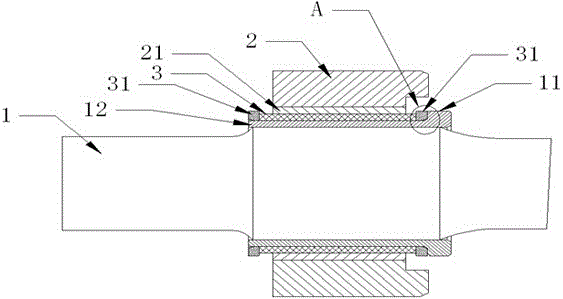

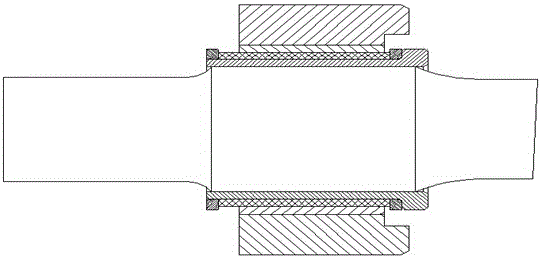

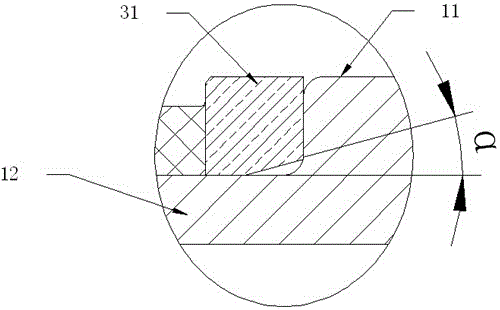

[0038] Such as Figure 1 to Figure 3 As shown, the new anti-side-rolling torsion bar system includes a torsion bar 1 and a spherical hinge support 2. The inner surface of the spherical hinge support 2 is equipped with a friction sleeve 3 through interference connection, and the friction sleeve 3 is sleeved on the torsion bar 1 through a clearance fit. The torsion bar 1 has a limit stop 11 that restricts the lateral movement of the friction sleeve 3, the friction sleeve 3 extends from the spherical hinge support 2 and the friction sleeve 3 extends beyond the end surface of the spherical hinge support 2 to be longer than the new anti-rolling torsion bar The cumulative tolerance of the system installed between the car body and the frame, the interference force between the friction sleeve 3 and the spherical hinge support 2 is greater than the lateral movement force o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com