Acrylic panel component adhesion tool

A panel component and acrylic technology, which is applied in the field of acrylic panel component bonding tooling, can solve the problems of acrylic panels being easy to bend, easy to produce errors, and low work efficiency, and achieve fast bonding, easy pick-up, and solve the effects of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0039] like Figure 4 As shown, the acrylic panel assembly bonding tooling includes a worktable 1, a positioning block 7, a first limit block 5, a second limit block 6, a clamping cylinder 9 and a pressing cylinder 2. Support leg 12, the bottom of support leg is provided with pulley 13, is convenient to carry.

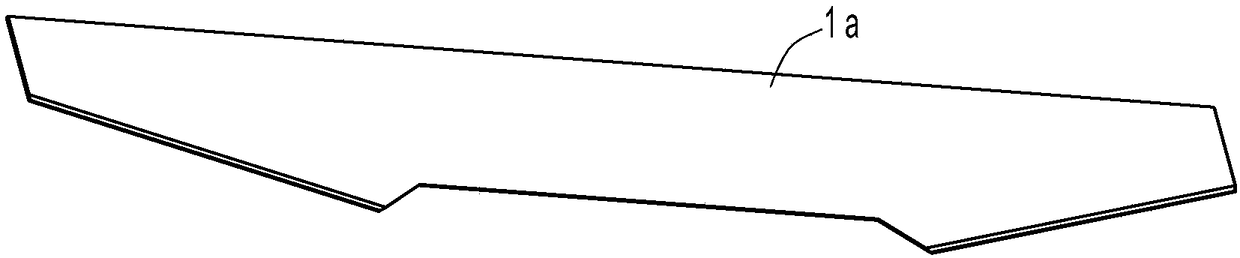

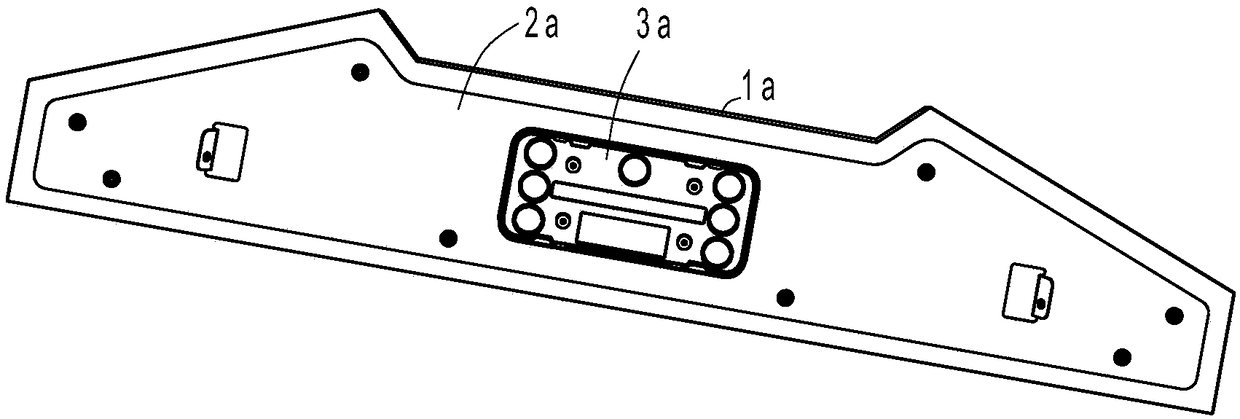

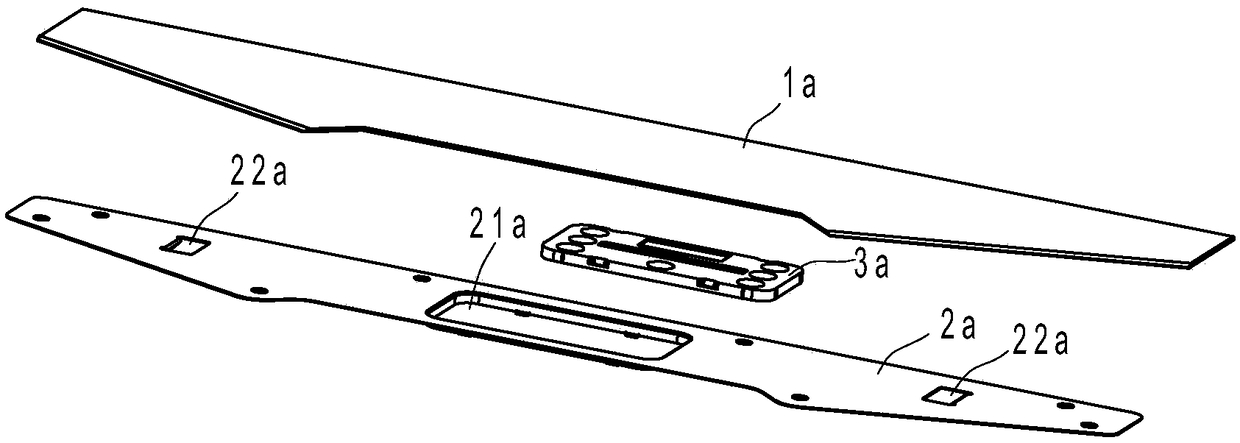

[0040] The upper end surface of the workbench 1 has an accommodating groove 111 for the installation of the switch fixing plate 3a; there are two positioning blocks 7 arranged around the accommodating groove 111, and the vertical direction of the positioning block 7 has elasticity and is used for positioning the connecting backplane. The second mounting hole 22a, the upper end surface of the positioning block 7 is a flat surface capable of contacting the acrylic panel 1a.

[0041] There are four first limit blocks 5 arranged around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com