Impurity recognition and removal device for agricultural stem-leaf products, and working method thereof

A technology for removing devices and agricultural products, applied in the field of automatic screening equipment, can solve problems such as unsatisfactory removal of impurities, high technical difficulty, and narrow application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

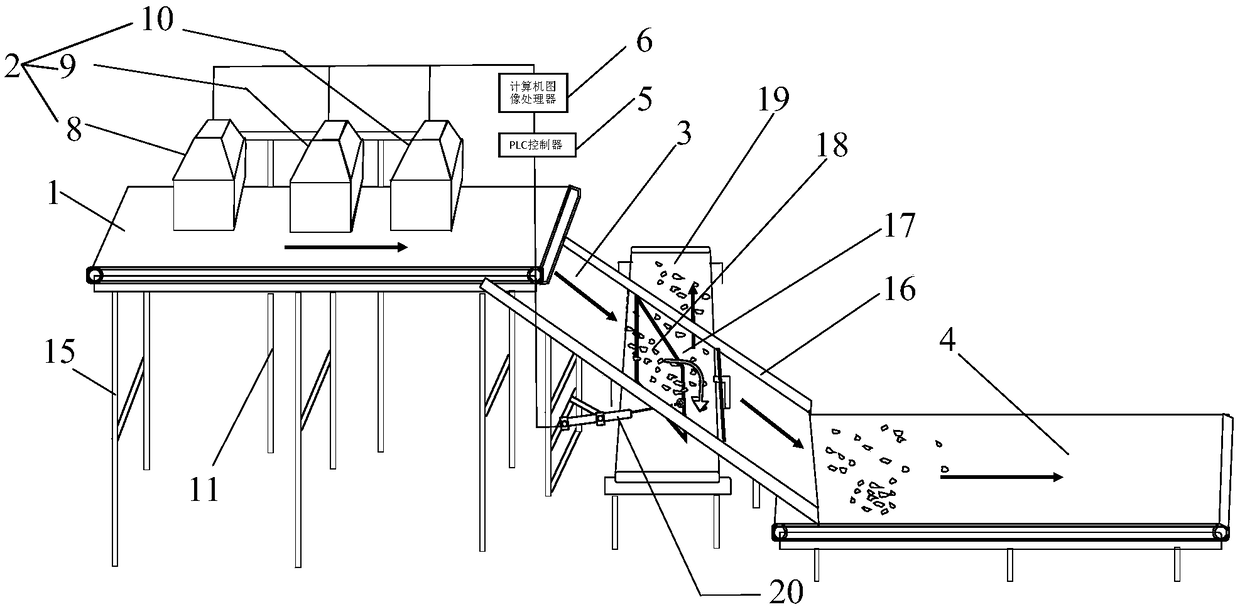

[0030] refer to figure 1 , this embodiment discloses a device for identifying and removing sundries in stem and leaf agricultural products. 4 and a PLC controller 5, the ultraviolet light detection imaging device 2 is arranged above the feed conveyor belt 1, the ultraviolet light emitted by the ultraviolet light detection imaging device 2 can completely irradiate the material on the feed conveyor belt 1, and the ultraviolet light detection Imaging device 2 is connected with PLC controller 5 through computer image processor 6, and described feeding slideway 3 is inclinedly arranged, and the two ends of feeding slideway 3 are respectively connected feed conveyor belt 1 and discharge conveyor belt 4, and described feeding slideway A blanking device is arranged on the channel 3, and the blanking device is connected with the PLC controller 5, and the PLC controller 5 controls the blanking device to remove impurities in the material.

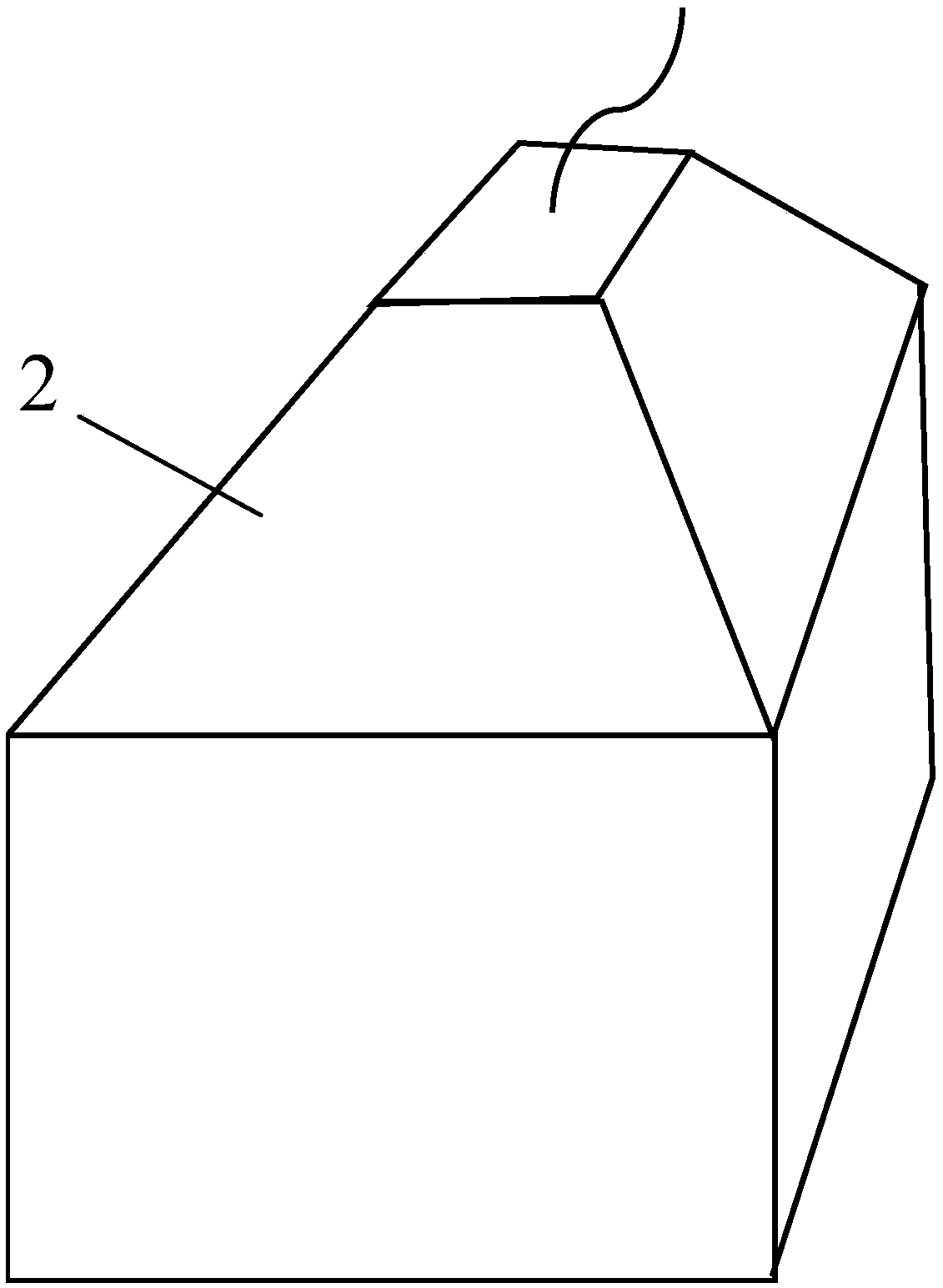

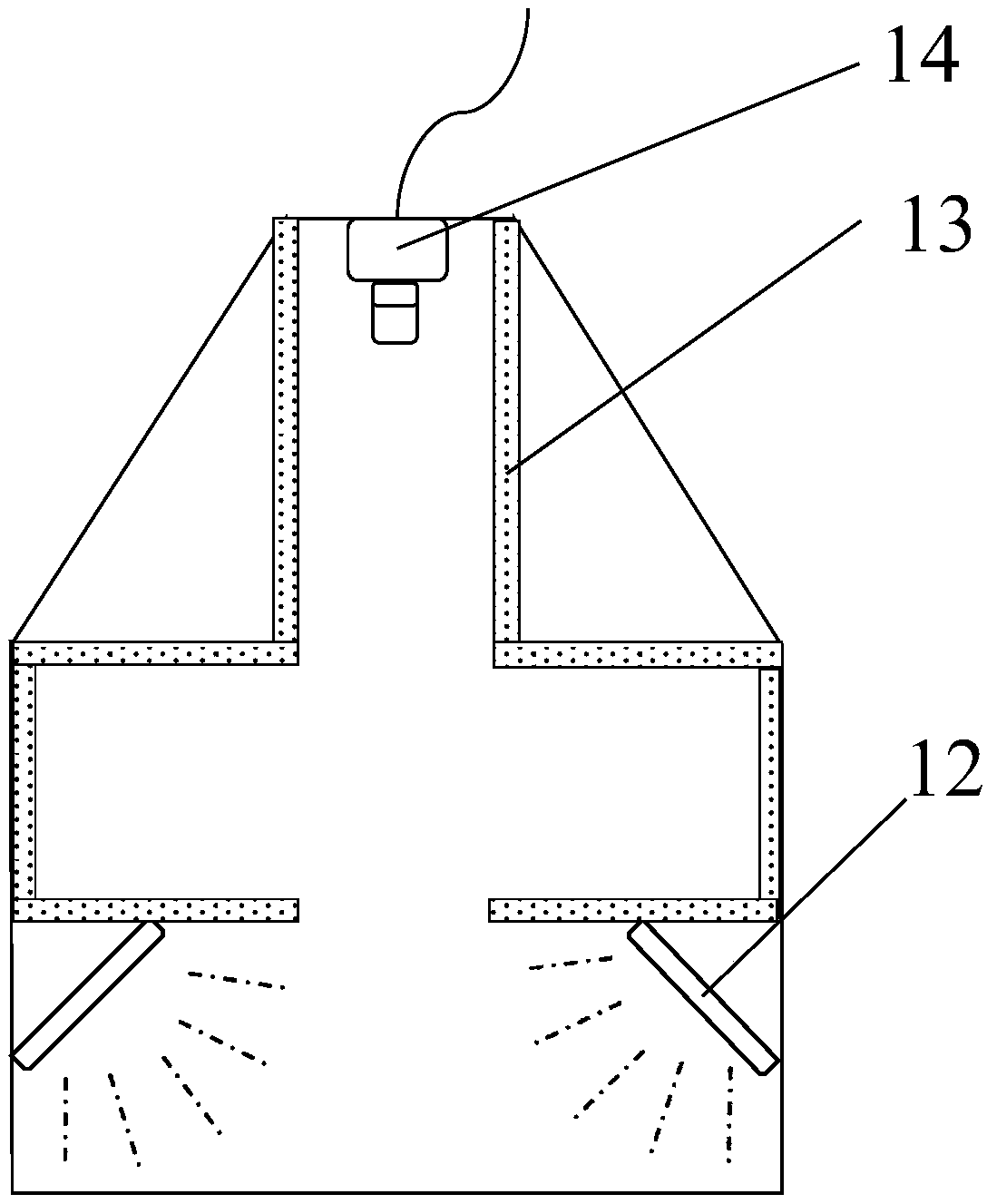

[0031] refer to figure 2 and image 3 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com