A safe non-radiative dielectric barrier discharge device

A dielectric barrier discharge and radiation-free technology, applied in the direction of electrical components, plasma, etc., can solve the problems of inconvenient adjustment of electrode distance, unsafe electrode exposure, electromagnetic radiation interference, etc., to reduce the risk of current breakdown through the air, shielding Electromagnetic radiation, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the content of the present invention will be further described in conjunction with the following embodiments, but the content of the present invention is not limited to the following embodiments.

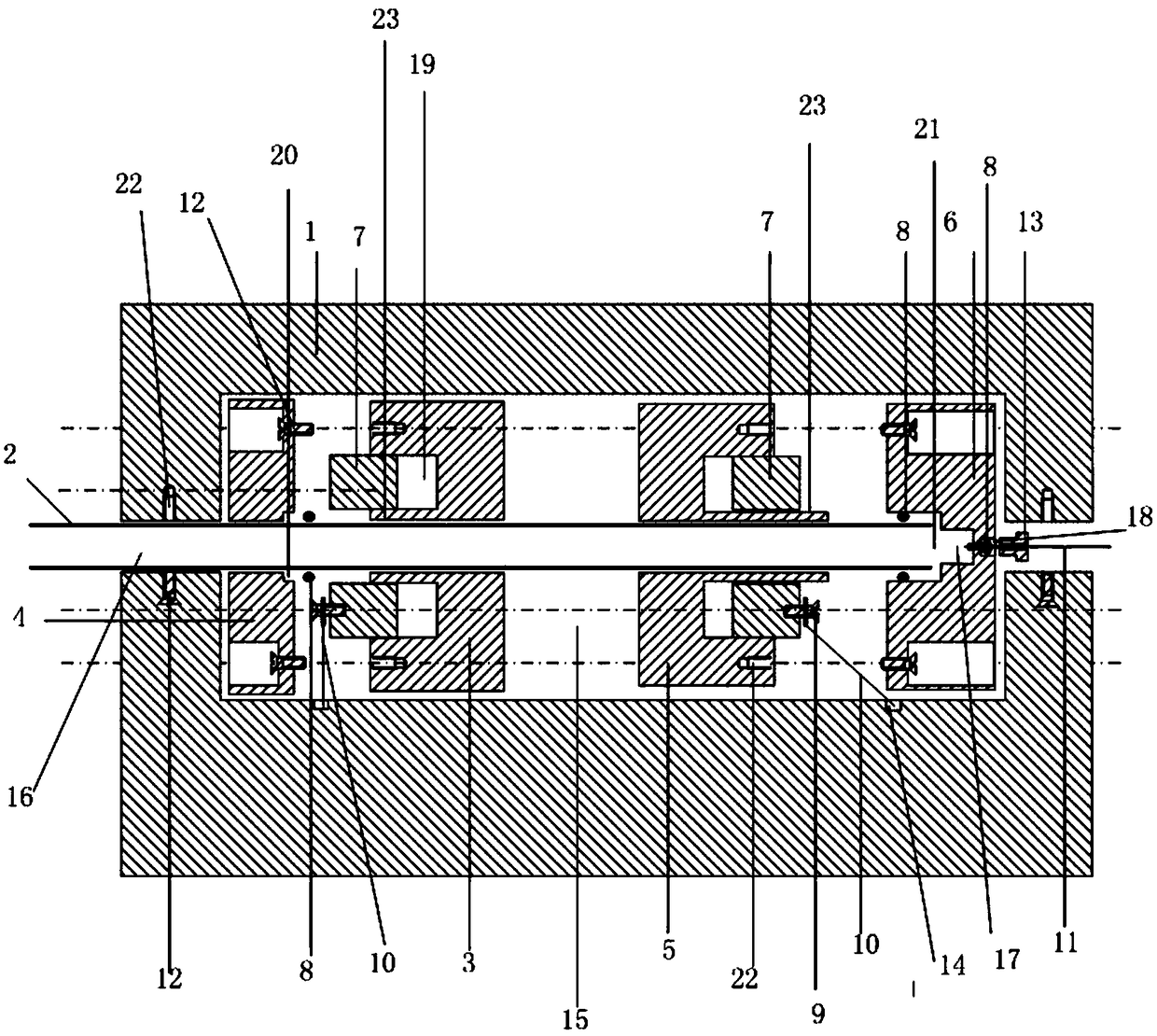

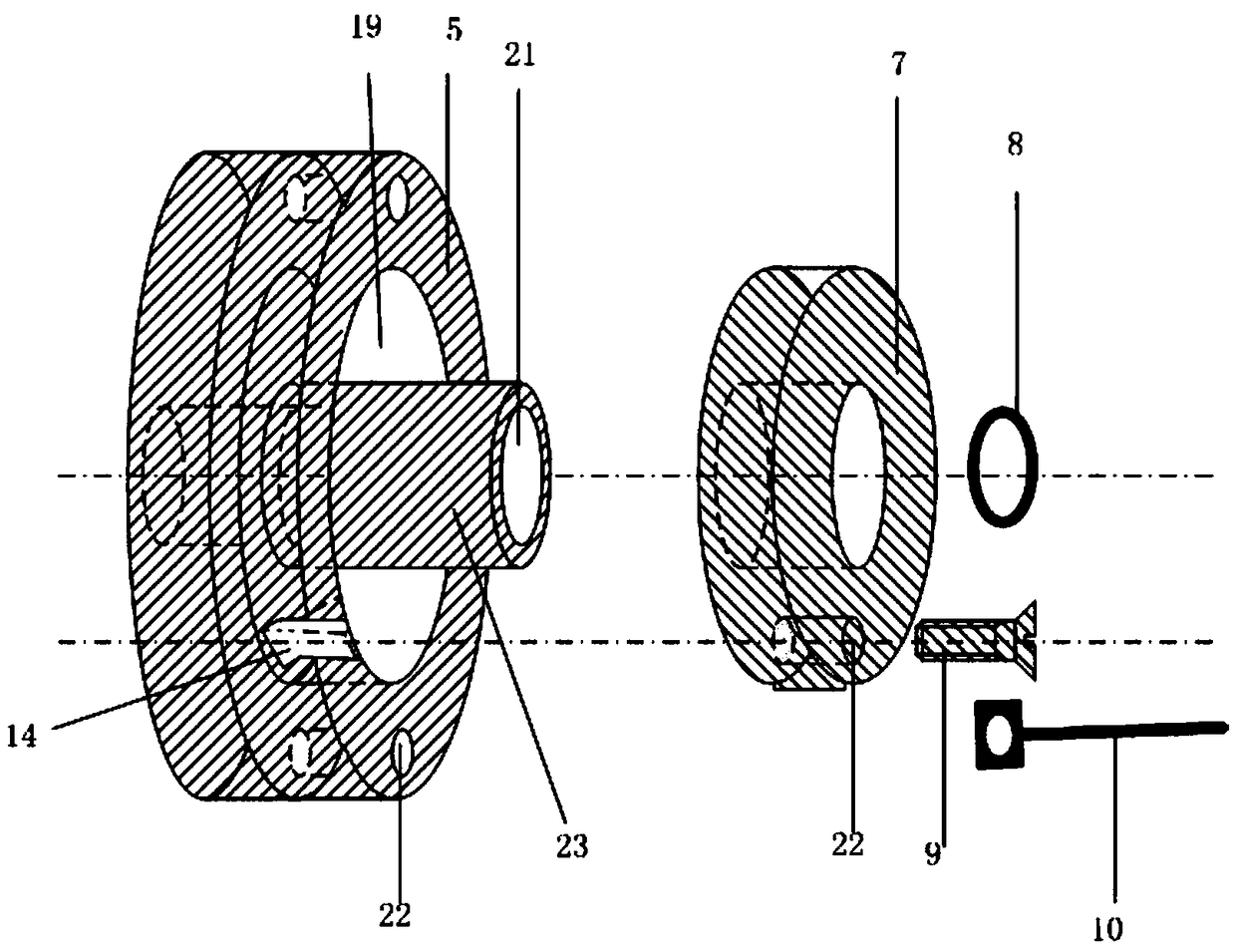

[0025] Embodiments of the present invention: in terms of materials: discharge tube (2), moving electrode tank (3), moving electrode tank cover (4), fixed electrode tank (5), sample holder (6) and fixing screws (12), The hollow screws (13) are all PFA plastics, the electrodes (7) are made of aluminum ingots and turned into rings, the terminal screws (9) are metal screws, and the O-rings (8) are nitrile rubber. Dimensions (unit: mm): discharge tube (2) inner diameter 4, outer diameter 6, wall thickness 1, length 300; electrode (7) inner diameter 8, outer diameter 18, ring width 5; movable electrode slot (4) and fixed The electrode groove (5) is 10 thick, the inner ring of the electrode groove (23) is 5 deep; the protruding part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com