Coaxial packaged laser and optical module

A laser, coaxial technology, used in lasers, laser parts, semiconductor lasers, etc., can solve problems such as large parasitic parameters, and achieve the effect of solving heat dissipation, shortening length, and ensuring heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

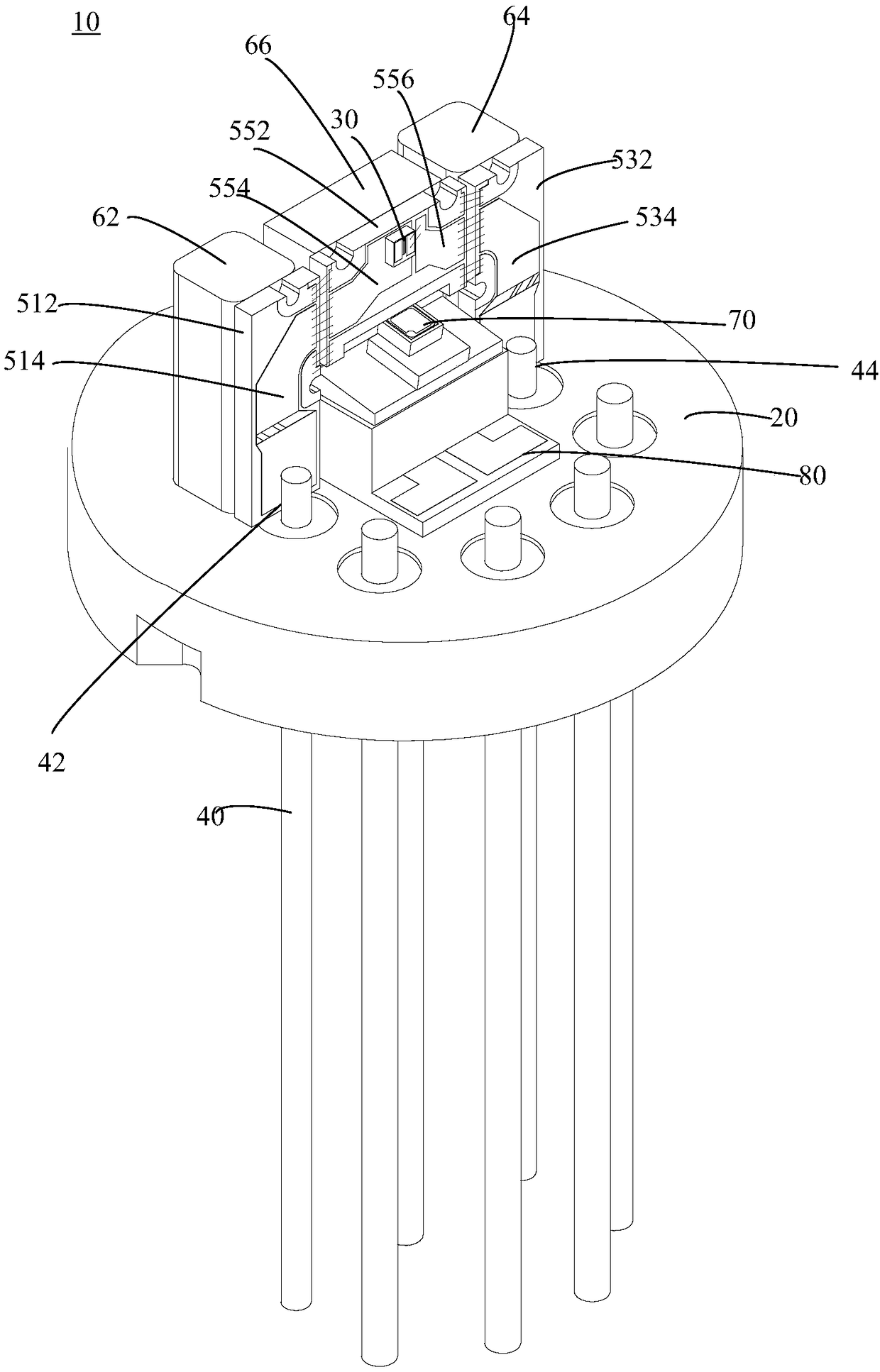

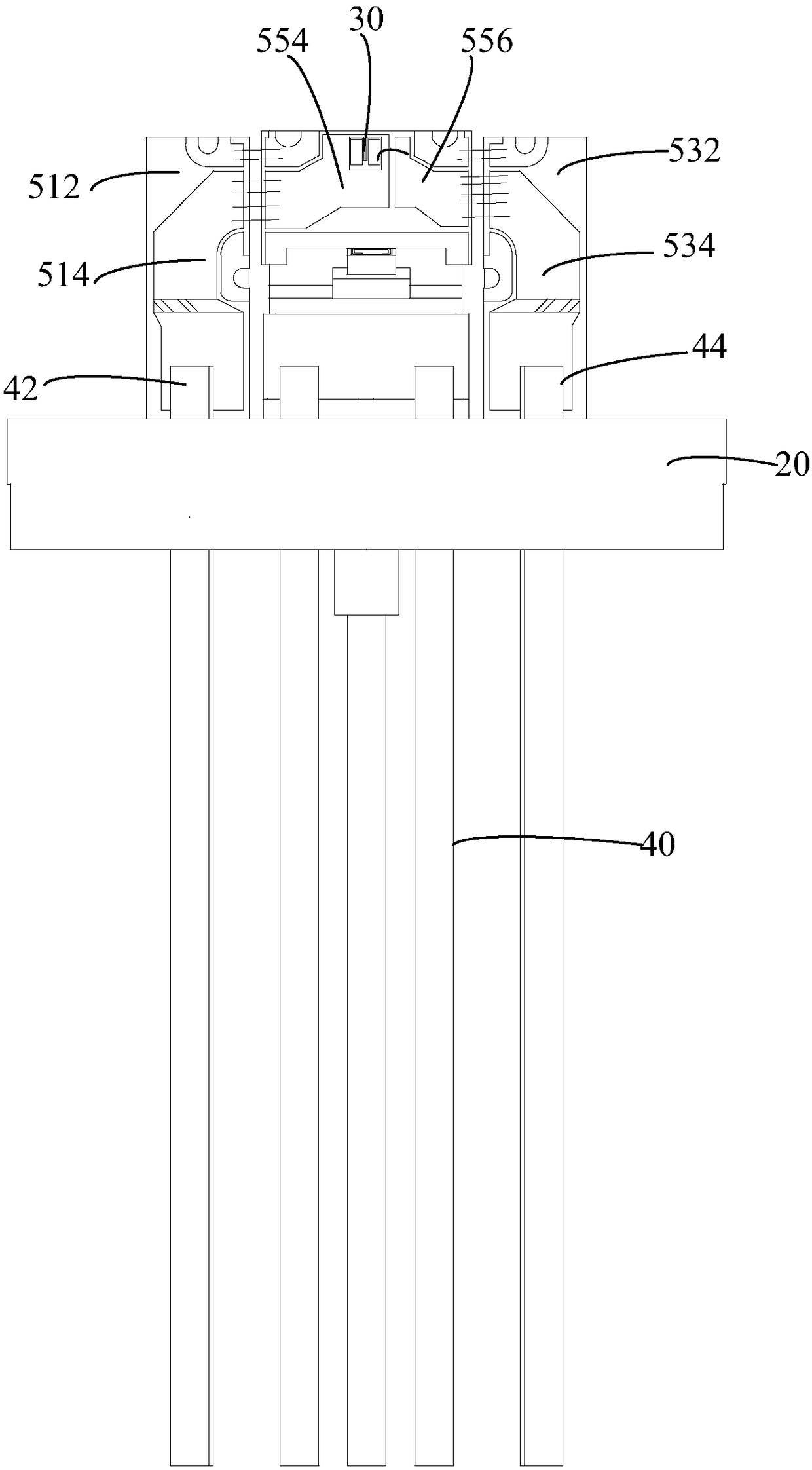

[0020] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0021] see figure 1 , in the existing package, the laser chip 1 is directly arranged on the transitional heat sink 5 . The positive and negative poles of the laser chip 1 need to be connected to the pin 3 of the tube base through the wire 3, and the gap between the pin 3 and the tube base 4 is sealed by glass, and the purpose of insulating the pin 3 and the tube base 4 is achieved, so as to realize the laser The positive electrode of the chip and the negative electrode of the laser chip are electrically connected to the outside separately.

[0022] In high-speed devices, the laser chip generates a lot of heat, and the heat dissipation of the transitional heat sink cannot meet the heat dissipation of the laser chip, resulting in the concentration of heat on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com