Method for distinguishing milk powder original production place through elemental analysis-stable isotope mass spectrometry

A technology of isotopic mass spectrometry and elemental analysis, which is applied in the field of milk powder quality inspection, can solve problems such as difficulty in detecting whey powder and non-dairy creamer, interfering element content, stable isotope ratio, and lack of identification means, etc., so as to improve market supervision and increase The effect of discrimination accuracy and test result accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A method for determining the origin of milk powder by elemental analysis-stable isotope mass spectrometry, comprising the following steps:

[0051] S1 Obtain samples of milk powder imported from multiple countries;

[0052] S2 detects stable carbon and nitrogen isotopes, stable hydrogen and oxygen isotopes, and analyzes multiple samples; S3 analyzes multiple samples for trace elements;

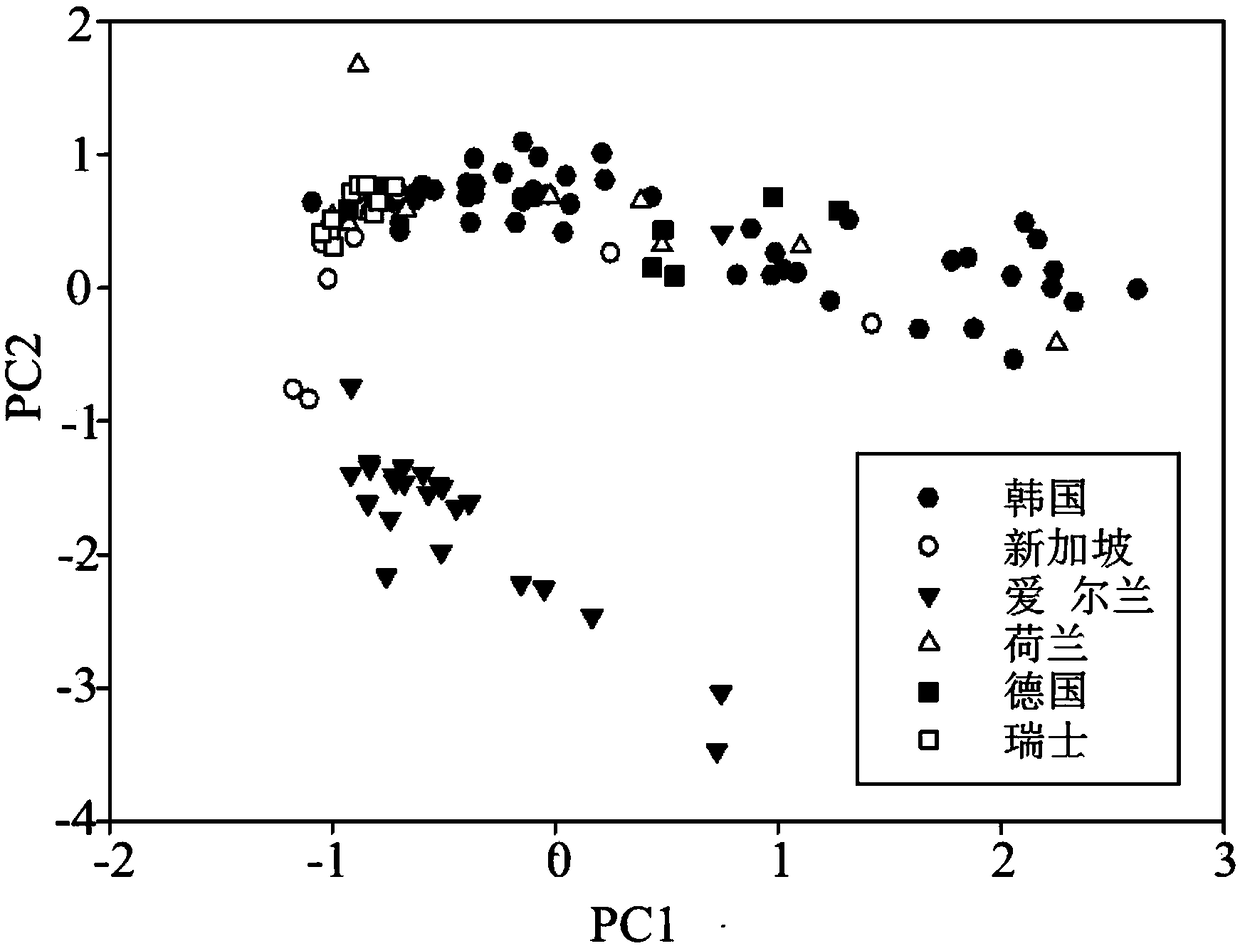

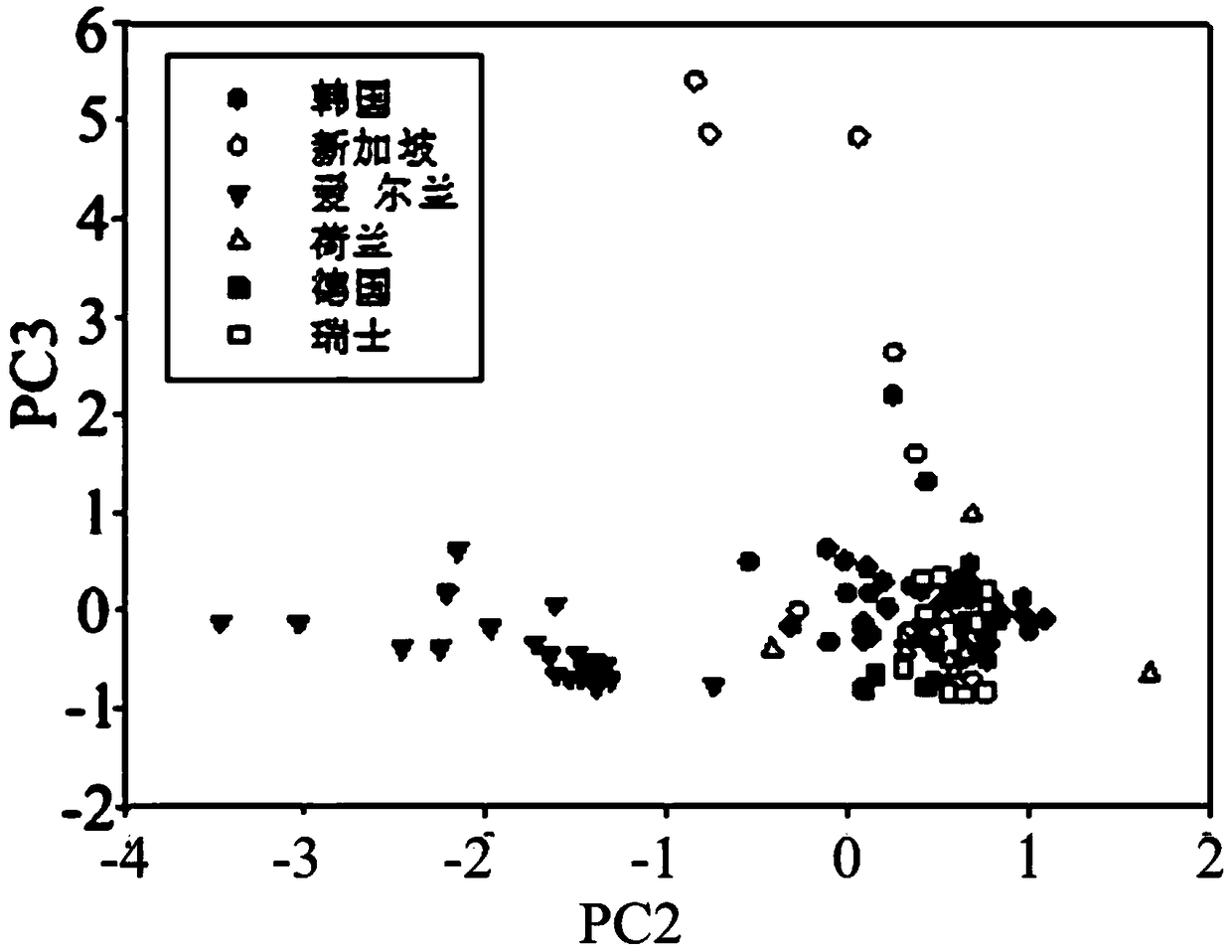

[0053] S4 uses the principal component analysis method to analyze the principal components of the elements in multiple samples, and preliminarily distinguishes the milk powder samples from different origins;

[0054] S5 adopts a plurality of sample origin information and the analysis data in S3, S4, utilizes discriminant analysis to carry out statistical modeling, obtains origin discriminant model coefficient matrix and corresponding origin discrimination prediction accuracy rate;

[0055] S6 brings unknown samples into the model to identify the origin, and finally judge the attribute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com