A method for judging the three-dimensional spontaneous combustion dangerous area in multi-layer goaf of coal seam group

A technology of dangerous areas and judgment methods, applied in the field of coal spontaneous combustion fire prevention, can solve the problems that the test method is difficult to apply to the three-dimensional space conditions of multi-layer goafs, and does not analyze the distribution rules and errors of spontaneous combustion dangerous areas, so as to achieve practicability and reliability. Strong operability, comprehensive area division, and fine judgment indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

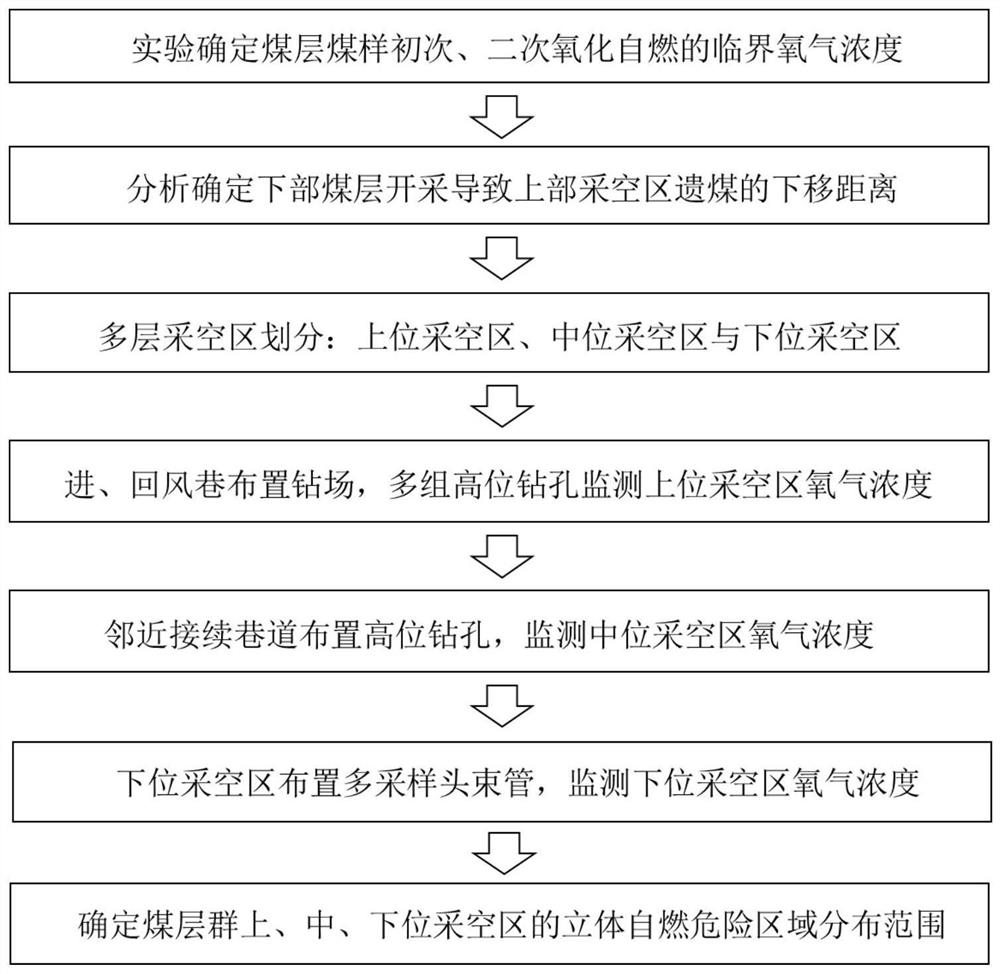

[0045] A method for judging the three-dimensional spontaneous combustion dangerous area in the multi-layer goaf of a coal seam group, the schematic diagram of the steps is shown in figure 1 , including the following steps:

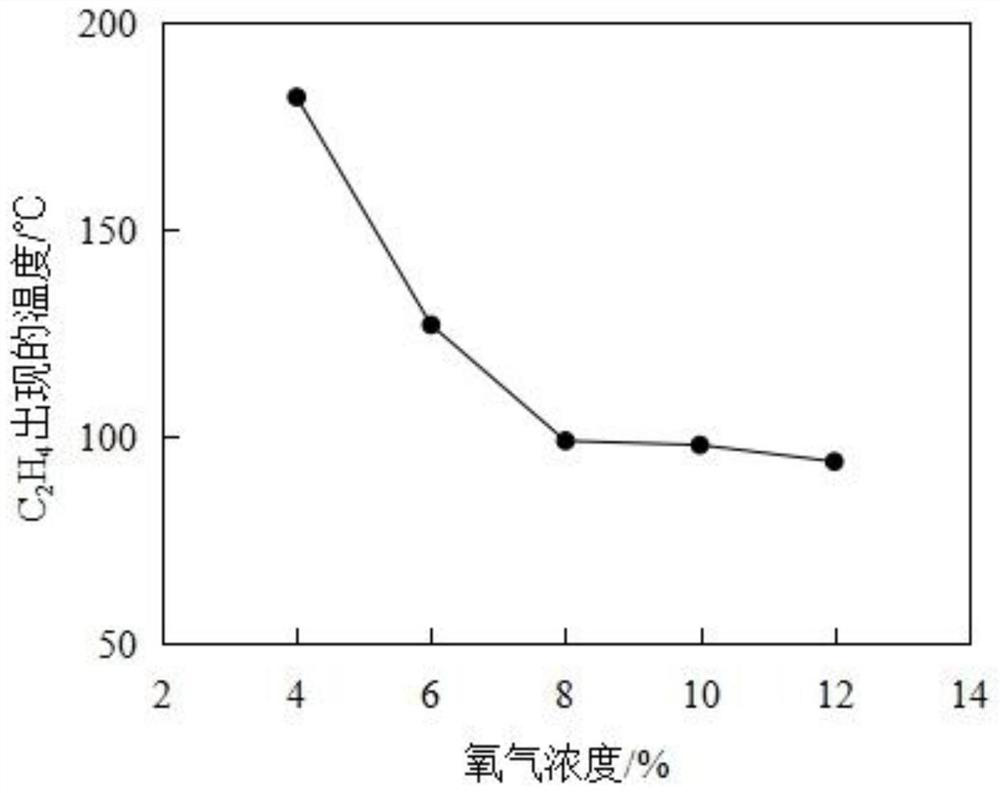

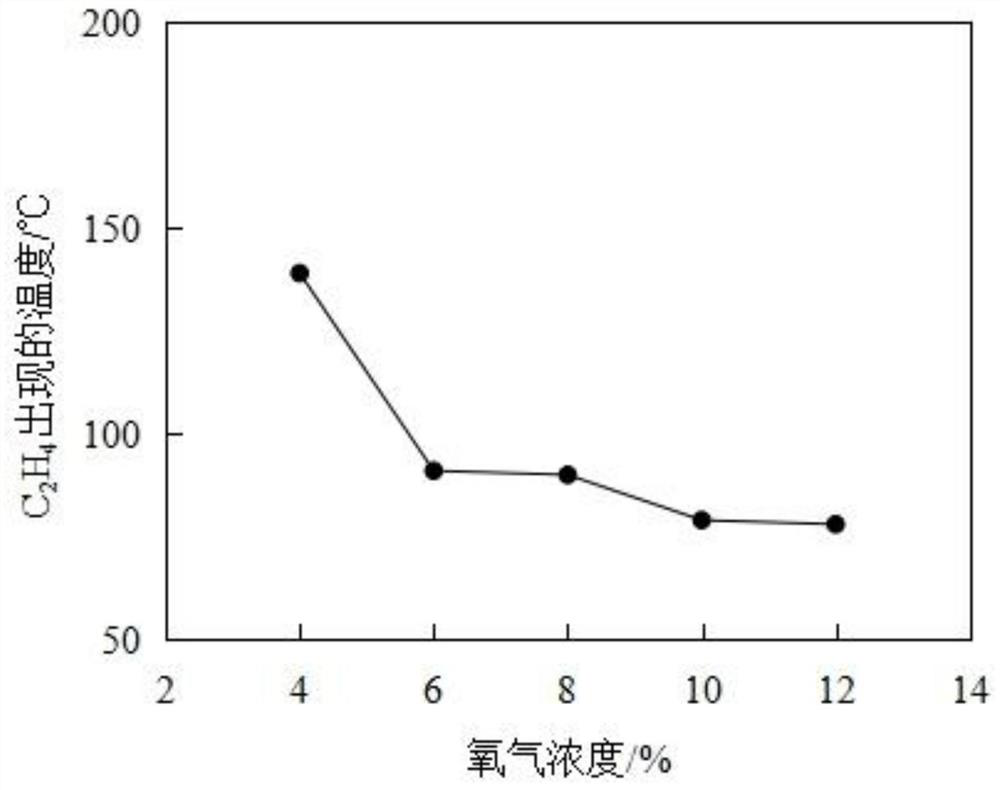

[0046] S1. Collect coal samples from the upper 8# coal seam and the lower 9# coal seam, conduct temperature-programmed oxidation experiments on coal samples in the laboratory, and determine the lower 9 The critical oxygen concentration at which primary oxidation and spontaneous combustion occurs in the coal samples of #coal seam, and the critical oxygen concentration at which secondary oxidation and spontaneous combustion occurs in the coal samples in the upper 8# coal seam.

[0047] In this step, (1) the collected coal samples of 8# coal seam and 9# coal seam are sealed and packaged with multi-layer plastic film, transported to the laboratory, and rotated until the particle size is less than 1mm.

[0048] (2) For the temperature-programmed oxidation expe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com