Engine blade measuring device

A technology of engine blades and measuring devices, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of affecting the distance between the intake and exhaust edges, affecting the processing quality of blades, and measuring instability, so as to ensure consistent repeated measurements Sexuality, compact structure, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

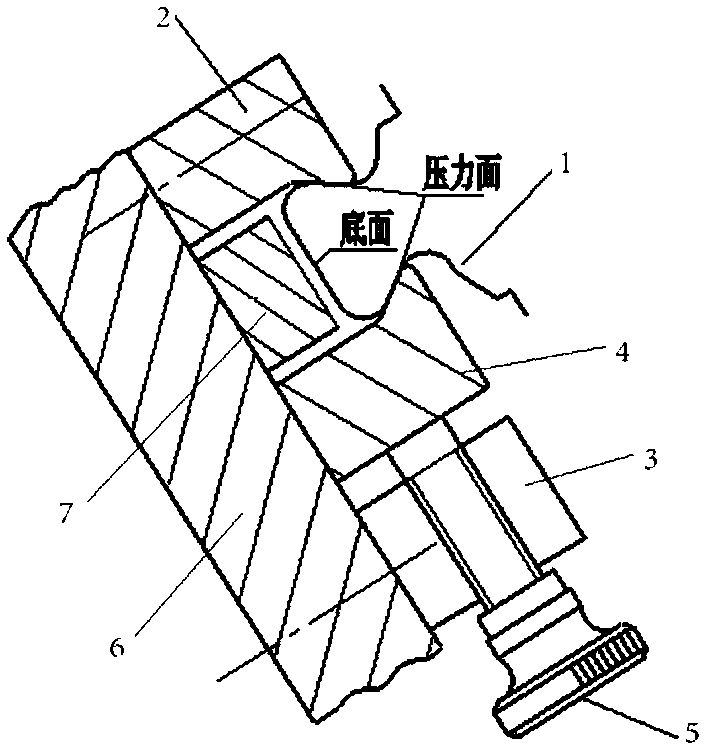

[0020] like figure 1 As shown, the present invention includes a base 6 and a positioning block 2 and a pressing block 4 that are relatively arranged on the base 6, wherein the positioning block 2 is fixedly connected to the base 6, and the pressing block 4 can translate on the base 6 for positioning. The opposite side of the block 2 and the pressing block 4 is provided with a force application surface corresponding to the pressure surface of the blade tenon 1. The structure of the positioning block 2 and the compression block 4 is the same, and the force application surface matches the pressure surface of the blade tenon 1. ; It also includes a support block 7 arranged between the positioning block 2 and the pressing block 4, the top surface of the supporting block 7 is attached to the bottom surface of the blade tenon 1; in addition, the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com