A screw air compressor with energy saving and environmental protection functions

An air compressor and screw technology, applied in the field of production and manufacturing, can solve the problems of affecting the air compression effect, affecting the gas quality, and affecting the service life, so as to reduce the generation of noise, improve the gas quality and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

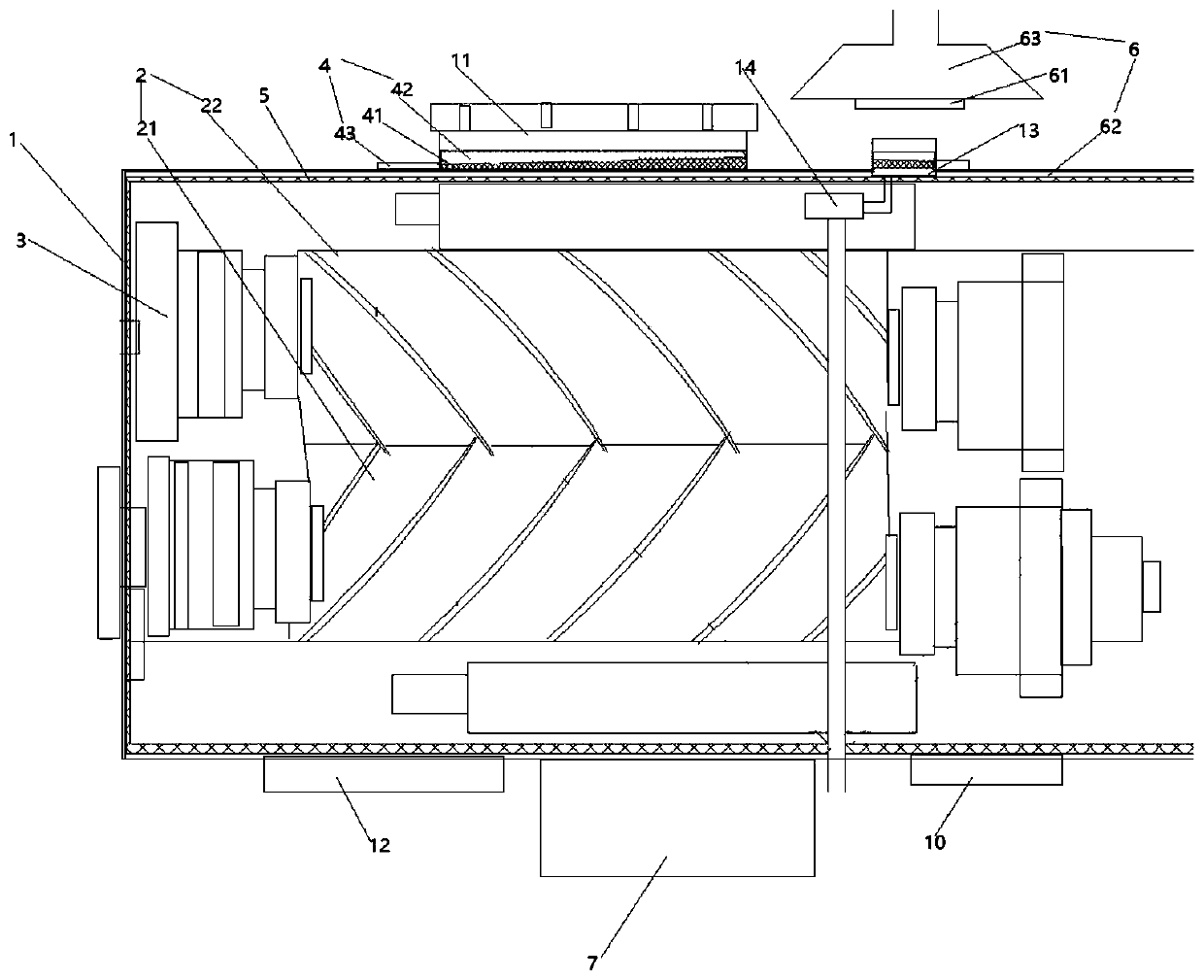

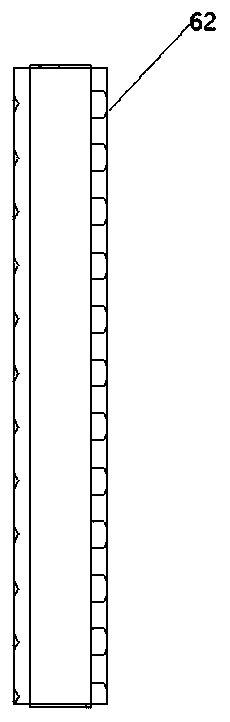

[0034] Such as Figure 1 to Figure 3 The shown screw air compressor with energy-saving and environmental protection functions includes: a housing 1, a screw 2, a driving mechanism 3, a filter device 4, a sound-absorbing device 5, a heat dissipation mechanism 6 and a control device 7, wherein the housing The body 1 is provided with an air inlet 11, an air outlet 12 and a cooling hole 13, the screw 2 is arranged on the housing 1, the driving mechanism 3 is connected with the screw 2, and the filter device 4 is arranged at the air inlet 11 and cooling holes 13, the sound-absorbing device 5 is arranged on the housing 1, the cooling mechanism 6 is connected to the cooling holes 13, the driving mechanism 3, the filter device 4, the sound-absorbing device 5 and the cooling mechanism 6 are all connected to the control device 7 connections.

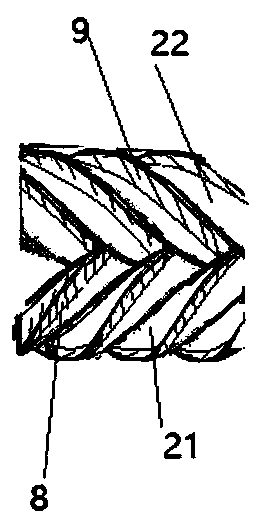

[0035] In this embodiment, the screw 2 adopts twin screws, wherein a male screw 21 and a female screw 22 are provided. The male screw 21 is prov...

Embodiment 2

[0045] Such as Figure 1 to Figure 3 The shown screw air compressor with energy-saving and environmental protection functions includes: a housing 1, a screw 2, a driving mechanism 3, a filter device 4, a sound-absorbing device 5, a heat dissipation mechanism 6 and a control device 7, wherein the housing The body 1 is provided with an air inlet 11, an air outlet 12 and a cooling hole 13, the screw 2 is arranged on the housing 1, the driving mechanism 3 is connected with the screw 2, and the filter device 4 is arranged at the air inlet 11 and cooling holes 13, the sound-absorbing device 5 is arranged on the housing 1, the cooling mechanism 6 is connected to the cooling holes 13, the driving mechanism 3, the filter device 4, the sound-absorbing device 5 and the cooling mechanism 6 are all connected to the control device 7 connections.

[0046] In this embodiment, the screw 2 adopts twin screws, wherein a male screw 21 and a female screw 22 are provided. The male screw 21 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com