A kind of electrophoretic coating and preparation method thereof

A technology of electrophoretic coatings and epoxy resins, applied in the direction of electrophoretic coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of not considering environmental hazards, single branched chain functional groups, and no anti-pollution components, etc. Achieve the effect of improving the disadvantages of the coating film, high gloss, and good surface anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

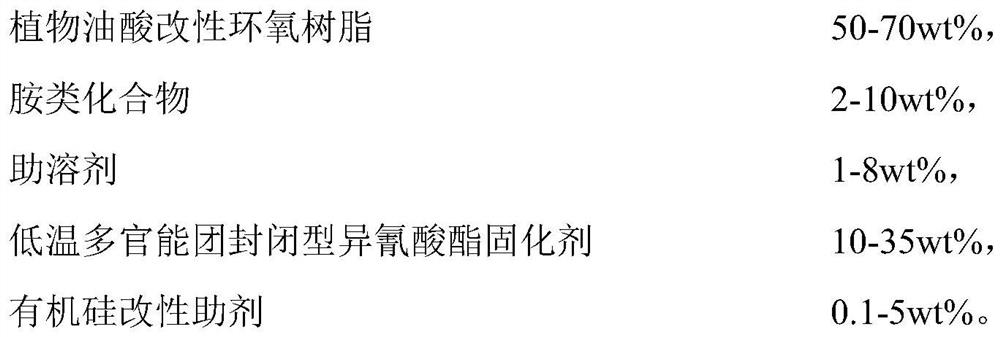

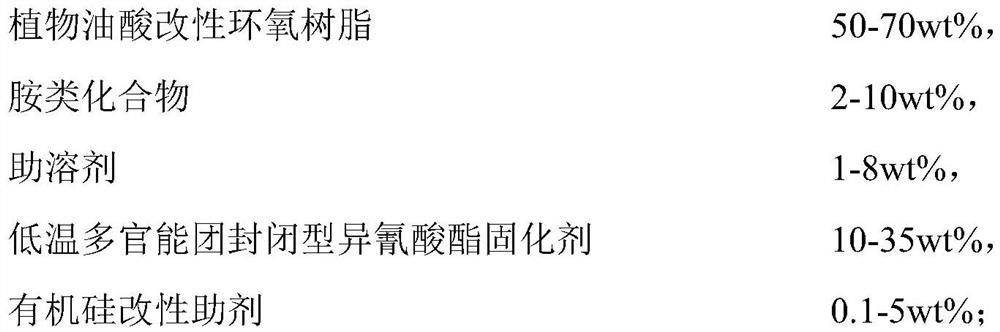

Method used

Image

Examples

Embodiment 1

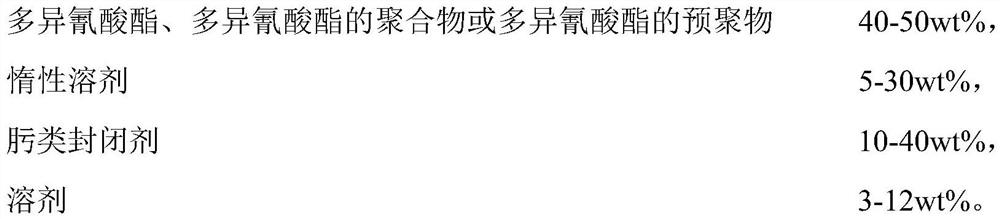

[0057] The preparation of low-temperature polyfunctional block type isocyanate curing agent, described preparation method comprises the following steps:

[0058] In a four-neck flask (manufactured by Collins of Shanghai Gaoxin Chemical Glass Co., Ltd.) with a condenser and nitrogen protection, put 454.5g of diphenylmethane diisocyanate (purchased from Wanhua Chemical Group Co., Ltd.) and 107.4g of formazan Base isobutyl ketone (purchased from Jinan Century Tongda Chemical Co., Ltd.), the temperature was raised to 40 ° C, and 301.4 g of methyl ethyl ketone oxime (purchased from Baishun (Beijing) Chemical Technology Co., Ltd.) was added dropwise, controlled at 45 ± 3 ° C, NCO The equivalent is controlled at 250-270; add 106.7g of ethylene glycol butyl ether (purchased from Jinan Century Tongda Chemical Co., Ltd.), after the addition, the temperature rises to 100°C, and it is kept at 100°C for 1 hour. The actual NCO equivalent is 48120, and the result is >42000 , adding 30.1 g of...

Embodiment 2

[0072] The preparation of low-temperature polyfunctional block type isocyanate curing agent, described preparation method comprises the following steps:

[0073] In a four-necked flask (manufactured by Collins of Shanghai Gaoxin Chemical Glass Co., Ltd.) with a condenser and nitrogen protection, put 480.2g of diphenylmethane diisocyanate (purchased from Wanhua Chemical Group Co., Ltd.) and 123.2g of formazan Base isobutyl ketone (purchased from Jinan Century Tongda Chemical Co., Ltd.), the temperature was raised to 40 ° C, and 315.3 g of methyl ethyl ketone oxime (purchased from Baishun (Beijing) Chemical Technology Co., Ltd.) was added dropwise, controlled at 45 ± 3 ° C, NCO The equivalent is controlled at 250-270; add 127.3g of ethylene glycol butyl ether (purchased from Jinan Century Tongda Chemical Co., Ltd.), after the addition, the temperature rises to 100°C, and it is kept at 100°C for 1 hour. The actual NCO equivalent is 48120, and the result is >42000 , add 32.5g of m...

Embodiment 3

[0087] The preparation of low-temperature polyfunctional block type isocyanate curing agent, described preparation method comprises the following steps:

[0088]In a four-necked flask (manufactured by Collins of Shanghai Gaoxin Chemical Glass Co., Ltd.) with a condenser and nitrogen protection, put 421.6g of diphenylmethane diisocyanate (purchased from Wanhua Chemical Group Co., Ltd.) and 108.2g of formazan Base isobutyl ketone (purchased from Jinan Century Tongda Chemical Co., Ltd.), the temperature was raised to 40 ° C, and 304.5 g of methyl ethyl ketone oxime (purchased from Baishun (Beijing) Chemical Technology Co., Ltd.) was added dropwise, controlled at 45 ± 3 ° C, NCO The equivalent is controlled at 250-270; add 103.5g of ethylene glycol butyl ether (purchased from Jinan Century Tongda Chemical Co., Ltd.), after the addition, the temperature rises to 100°C, and it is kept at 100°C for 1 hour. The actual NCO equivalent is 48120, and the result is >42000 , add 42.7g of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com