Continuous belt type sludge dryer and method for treating sludge in batches

A sludge drying and continuous belt technology, applied in the direction of dehydration/drying/thickened sludge treatment, dryer, drying gas arrangement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

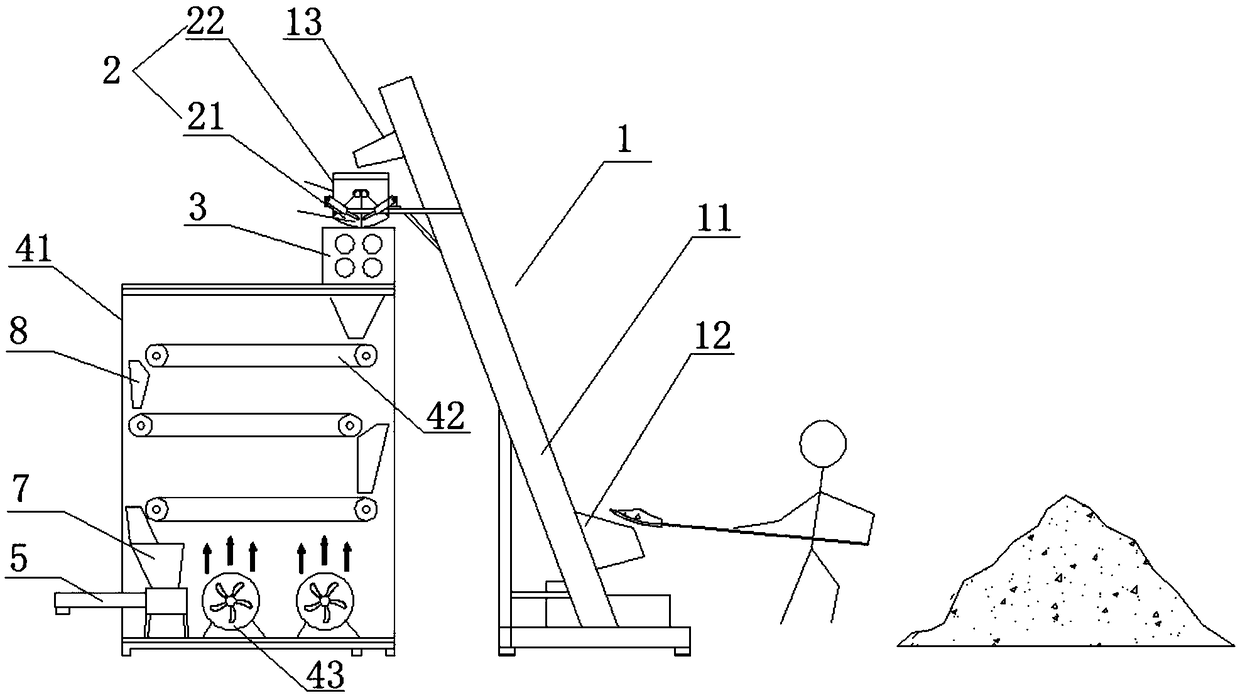

[0064] Such as figure 1 As shown, a continuous belt sludge dryer is used to dry small batches of sludge, including: a feeding mechanism 1 that lifts the sludge from the bottom to the top, temporarily storing sludge and controlling the amount of sludge output, and the bottom belt There is a feed speed control mechanism 2 with a pneumatic gate valve 21, a sludge cutting mechanism 3, a material drying system for drying sludge, a discharge mechanism 5, and a controller processing unit. The feed speed control mechanism 2 is located in the feed mechanism 1 Below the discharge port, the feeding speed control mechanism 2, the sludge cutting mechanism 3, and the material drying system are arranged in sequence from top to bottom, and the discharging mechanism 5 is close to the bottom of the material drying system; the feeding mechanism 1, the feeding speed control Mechanism 2, sludge cutting mechanism 3, material drying system, and discharge mechanism 5 are all electrically connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com