Double brake electric hoist fault emergency load safe release system and method

An electric hoist and safety release technology, applied in hoisting devices, spring mechanisms, etc., can solve the problems of potential safety hazards, no safety protection, failure of the first brake, etc., achieve safe and controllable speed, and ensure ease of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Typical examples of the present invention will be described in detail below in conjunction with the accompanying drawings.

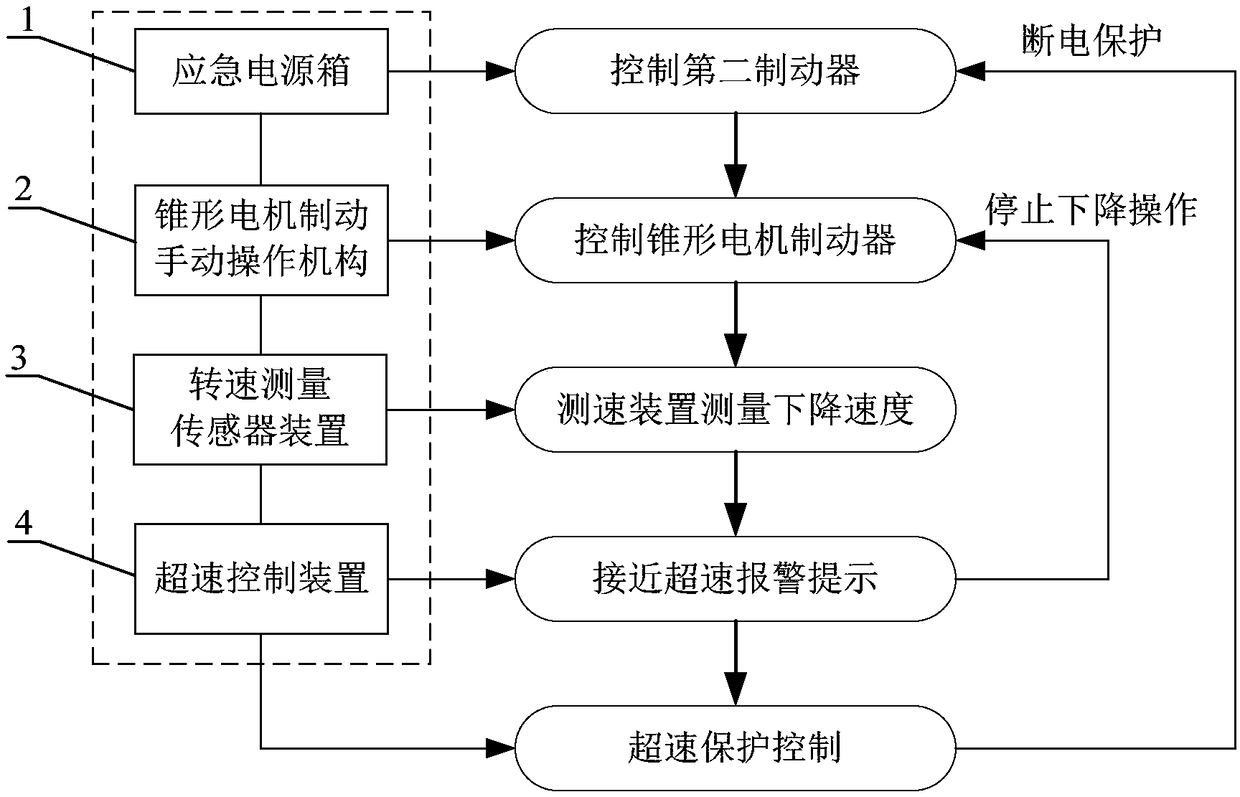

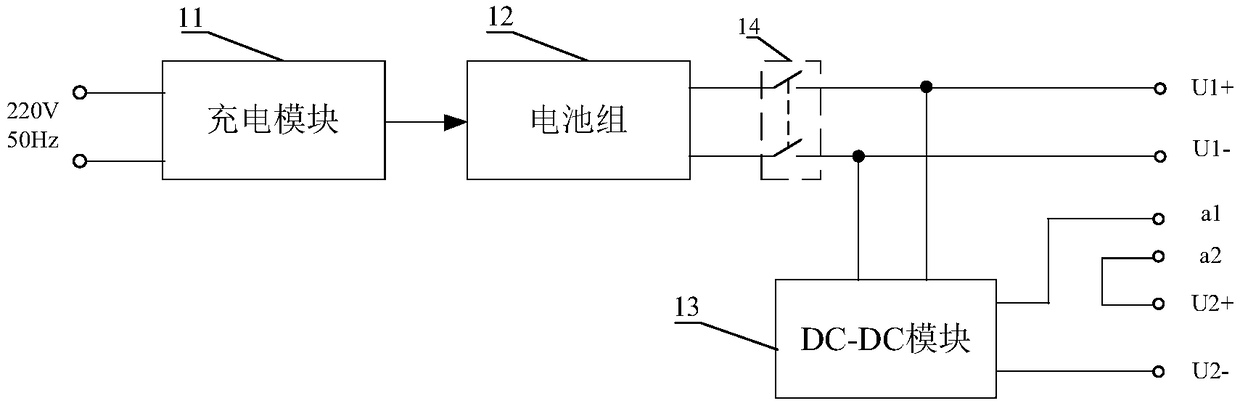

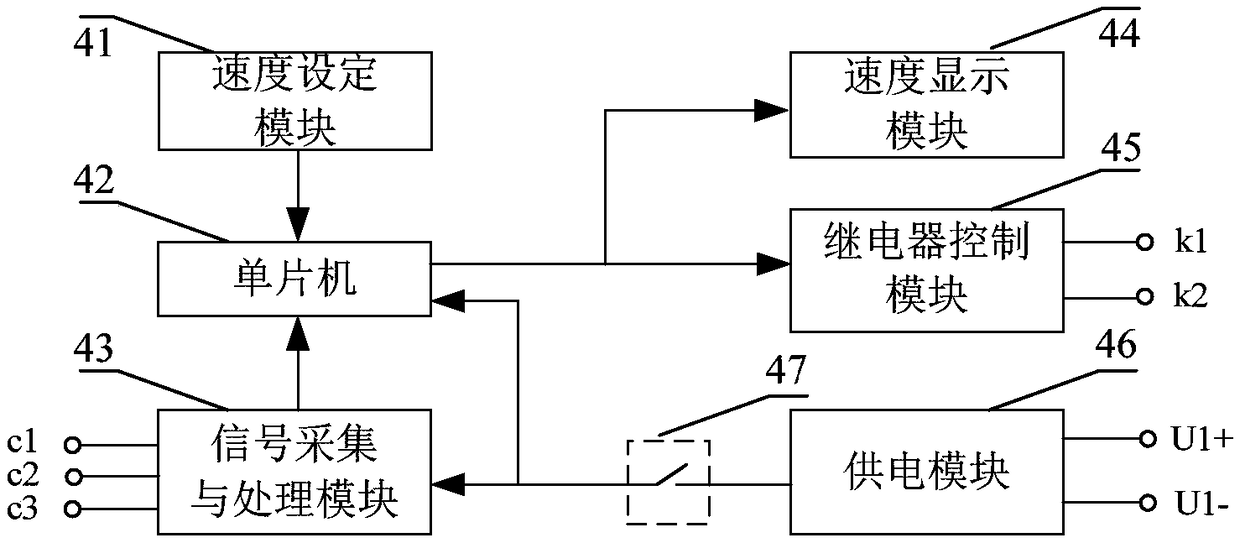

[0040] like figure 1 As shown, the present invention provides a dual-brake electric hoist emergency load safety release system, including an emergency power supply box 1, a cone motor brake manual operating mechanism 2, a rotational speed measurement sensor device 3 and an overspeed control device 4.

[0041]When working, the second brake is first controlled to be opened through the power supply of the emergency power supply box 1, and then the first brake is gradually opened by manually operating the conical brake operating mechanism 2, so that the weight is slowly lowered, and the speed measuring sensor device 3 installed on the reel is at the same time Measure the lowering speed of the heavy object; when the lowering speed of the heavy object is close to the set value, an audible and visual alarm will be given through the overspeed control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com