Multiple-head automatic filling machine and its control method

A filling machine and filling technology, applied in the direction of computer control, general control system, control/adjustment system, etc., can solve the problems of not being able to form a suitable flexible filling system, adding filling heads, adjusting accuracy and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

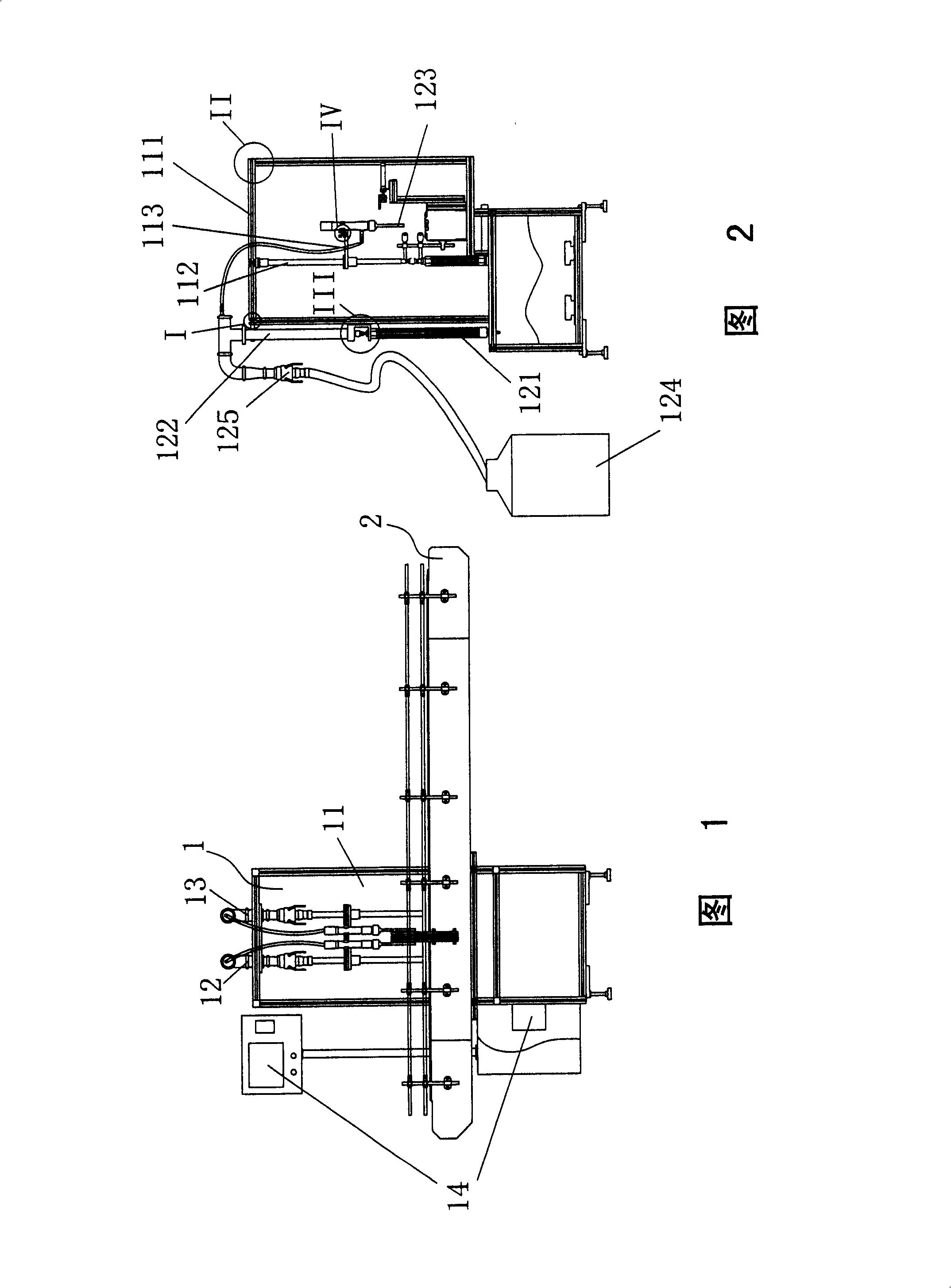

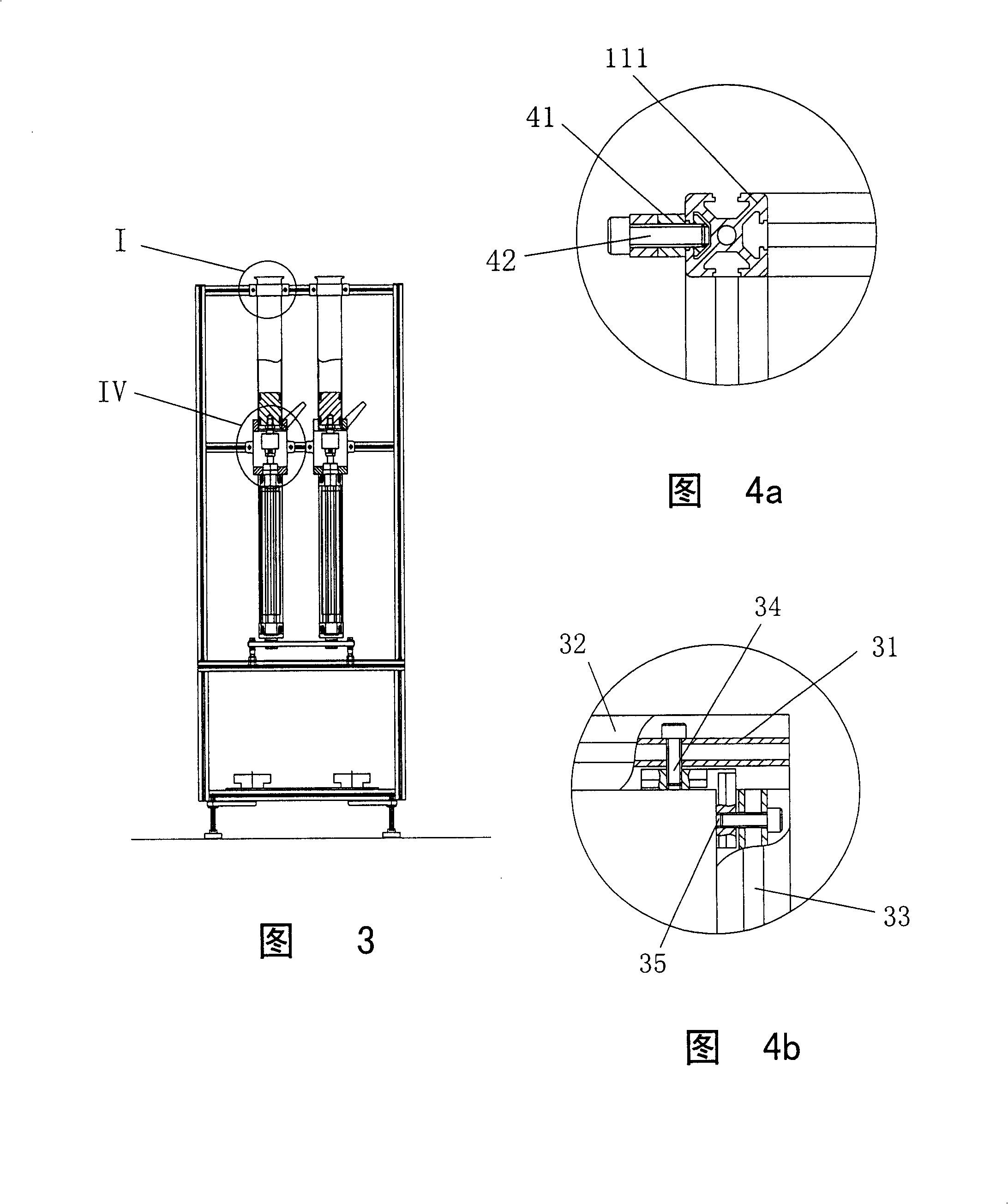

[0048] Please refer to Fig. 1-Fig. 3 at the same time first, Fig. 1 is the front view of the structural diagram according to an embodiment of the present invention; Fig. 2 is the left view of the structural diagram according to an embodiment of the present invention; Fig. 3 is according to the present invention A rear view of a schematic structural diagram of an embodiment.

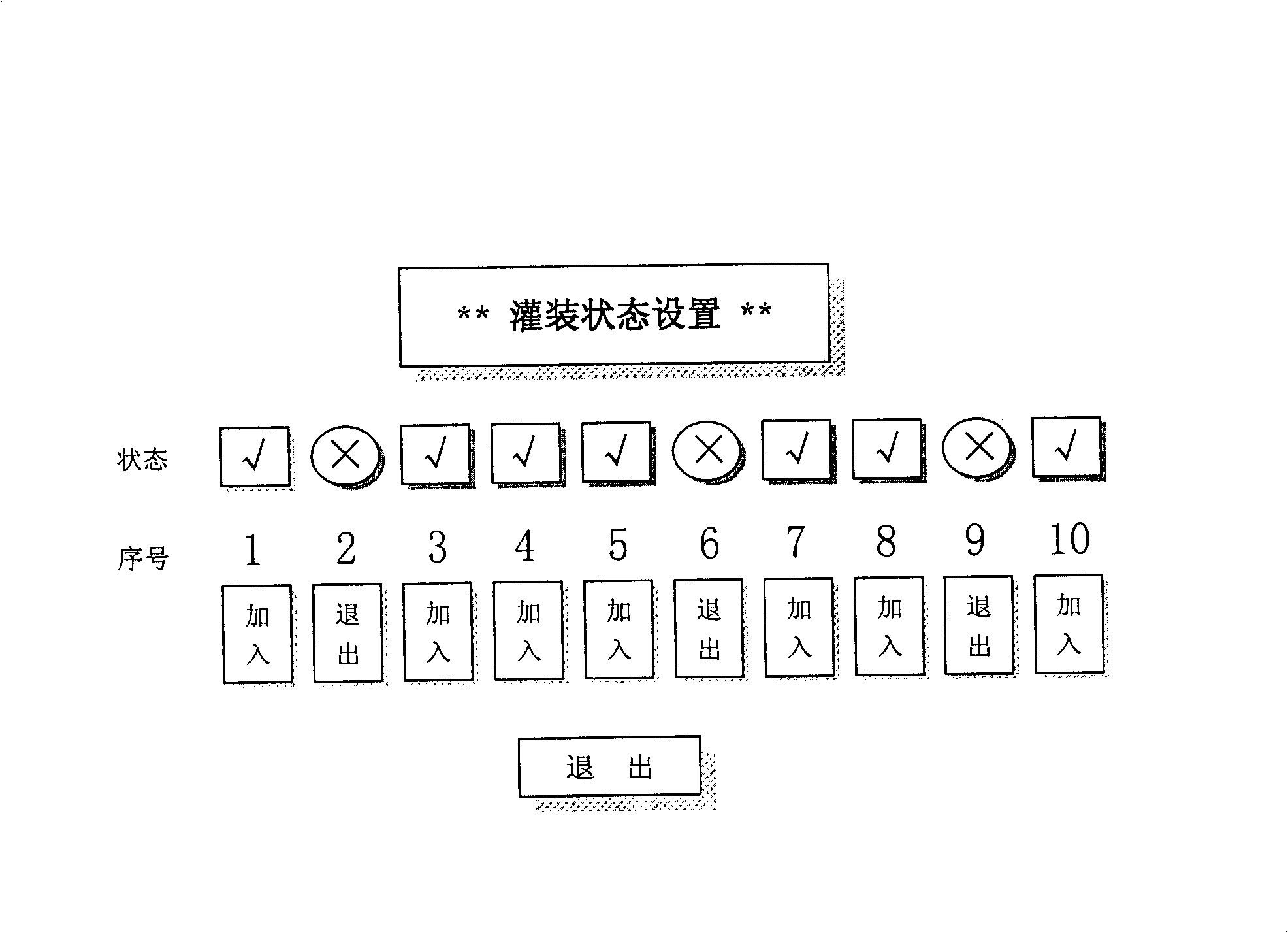

[0049] As shown in Fig. 1, a kind of multi-head automatic filling machine 1 provided by the present invention is positioned at the rear of conveying table 2, and filling machine 1 includes assembleable frame 11, two filling heads 12 and 13 and is used to control the A control system 14 for the number and status of filling heads.

[0050] Firstly, please describe the composition of the assembleable rack 11 of the present invention in conjunction with FIG. 2 . The frame 11 includes a frame 1 and a filling frame 112, the filling frame 112 is fixedly connected to the frame 111, and the filling frame 112 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com