Ampoule bottle printing and placing device

A technology for ampoules and printing, which is applied in the direction of conveyor control devices, packaging, packaging bottles, etc. It can solve the problems of increasing employees, shortage of funds, and increasing labor, so as to facilitate installation and replacement, avoid unclear writing, Avoid the effect of ink not drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

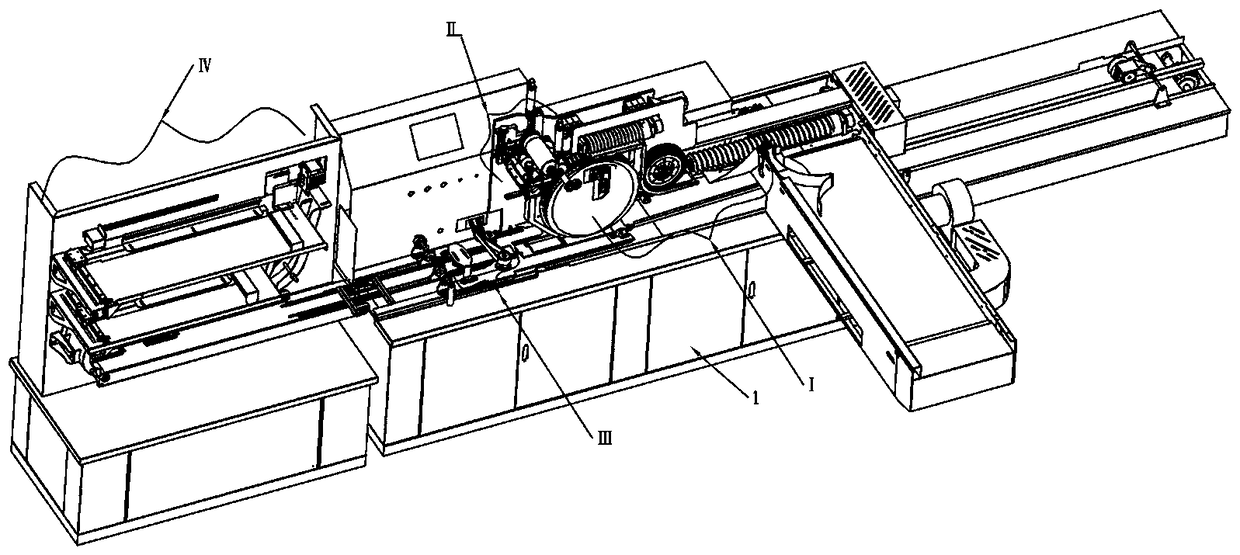

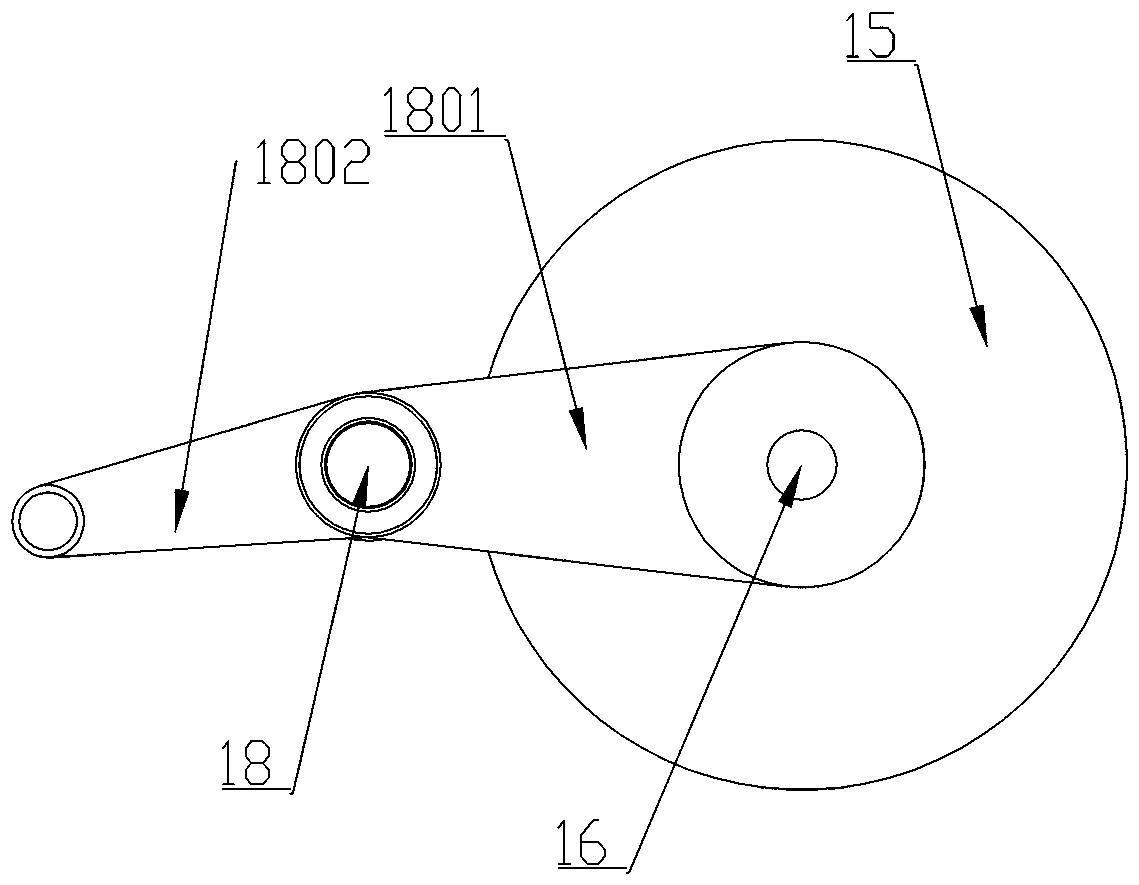

[0051] Embodiment 1, a kind of ampoule bottle printing and holding device, such as Figure 1-3 , including sequentially connected ampoule conveying mechanism I, printing mechanism II, sub-holding mechanism III and conveying-in-holding mechanism IV, the ampoule conveying mechanism I includes a frame 1 and a vertical plate 9 located behind the frame 1, the machine The primary conveying screw 2 and the first driving device 21 (prior art) that controls the rotation of the primary conveying screw 2 are installed on the frame 1, and one side of the frame 1 is provided with the head of the primary conveying screw 2 and stores The storage area 11 of the ampoule bottle, the bottom of the primary conveying screw 2 is a conveying platform 47, the tail of the primary conveying screw 2 is provided with a buffer mechanism installed on the vertical plate 9, and the bottom of the buffer mechanism is provided with Branch missing detection sensor 41 (prior art), the vertical plate 9 is provided...

Embodiment 2

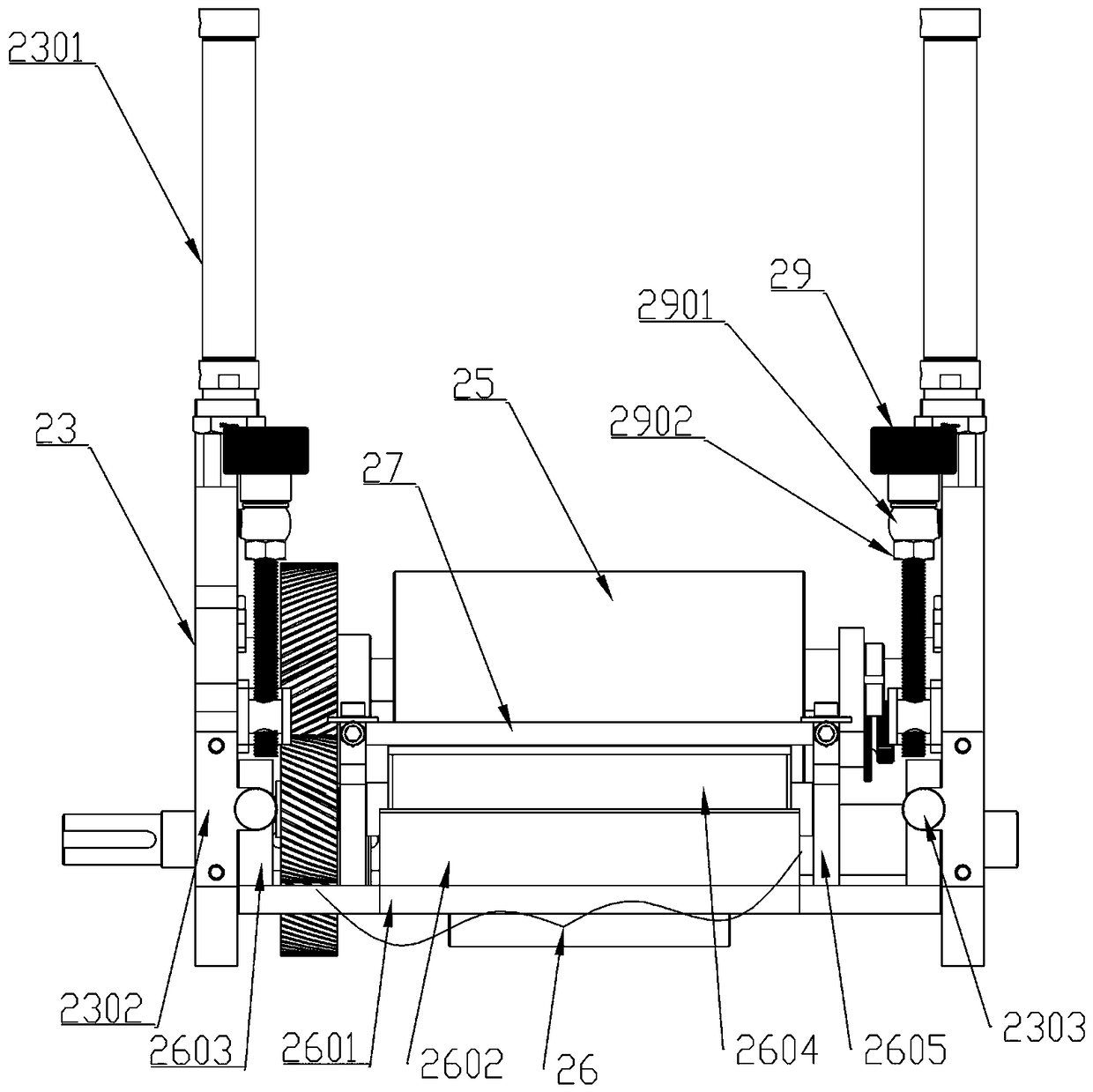

[0053] Embodiment two, such as Figure 11-16 , basically the same as the second embodiment, the difference is that the printing mechanism II includes an anilox roller 2604, a type roller 25 and A transfer roller 24, one end of the central axis of the transfer roller 24 is connected with a drive motor, and an ink cartridge mechanism 26 located below the anilox roller 2604 is arranged between the side plate supports 23 on both sides. One side of the anilox roller 2604 is provided with an ink scraping mechanism, and the ink cartridge mechanism 264 includes an ink storage box 2602 installed on the bottom plate 2601, and the ink storage box 2602 protrudes forward with an ink-staining groove located under the anilox roller 2604 2606, the ink scraping mechanism includes a scraper bracket 2605 located on both sides of the ink storage box 2602, a knife seat 27 with a scraper 2701 is installed above the scraper bracket 2605, and the scraper 2701 is connected to the net The pattern roll...

Embodiment 3

[0057] Embodiment three, such as Figure 17-20 , is basically the same as Embodiment 1 or 2, the difference is that the sub-support mechanism III includes a base 31 and a work frame 3101 fixed on the base 31, and the front of the work frame 3101 is provided with an upper and horizontally arranged Workbench, the top of the workbench is provided with a side push mechanism on the work frame 3101, and the work frame 3101 is provided with a chute 31011 matched with the side push mechanism, and the right side of the workbench Two separating baffles 36 are arranged oppositely, and the work frame 3101 is provided with a separation groove 31014 positioned on the right side of the workbench, and the right side of the separation baffle 36 is provided with and installed on the work frame 3101 and The adsorption mechanism that slides in the separation groove 31014, the right end of the workbench protrudes downwards and is fixed on the work frame 3101 and faces to the left side, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com