Self-heat preservation masonry wall sheet automatic production device

A production device and wall piece technology, applied in ceramic molding workshops, ceramic molding machines, manufacturing tools, etc., to achieve the effects of improving flatness, reducing cracking risks, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is an automatic production device for self-insulating masonry wall pieces, which is used for producing self-insulating masonry wall pieces.

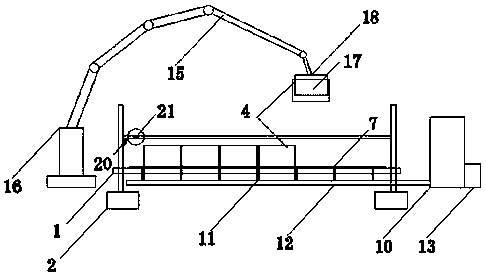

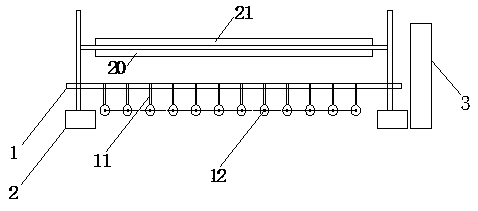

[0042] Industrialized production equipment for self-insulating exterior wall panels for prefabricated buildings, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes wall palletizing platform, wall template, brick loading machine, sizing machine, mechanical scraper, wall hoisting device and maintenance cleaning warehouse.

[0043] The wall palletizing platform is composed of a wall palletizing mold table 1, a rectangular steel plate 2 and a supporting frame 3. The rectangular steel plate is evenly distributed with a plurality of circular holes formed by the mold table grouting holes 4, the hole diameter is 8-10cm, The left and right spacing is the same as the length of the self-insulating block, the front and back spacing is the same as the height of the self-insulating block, the holes are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com