Waste plastic kind sorting device and sorting method thereof

A technology for waste plastics and sorting devices, applied in sorting and other directions, can solve the problems of limited application of electrostatic sorting, poor sorting accuracy by wind sorting, and large environmental pollution, and achieve the effects of improving sorting efficiency, protecting the environment, and increasing value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

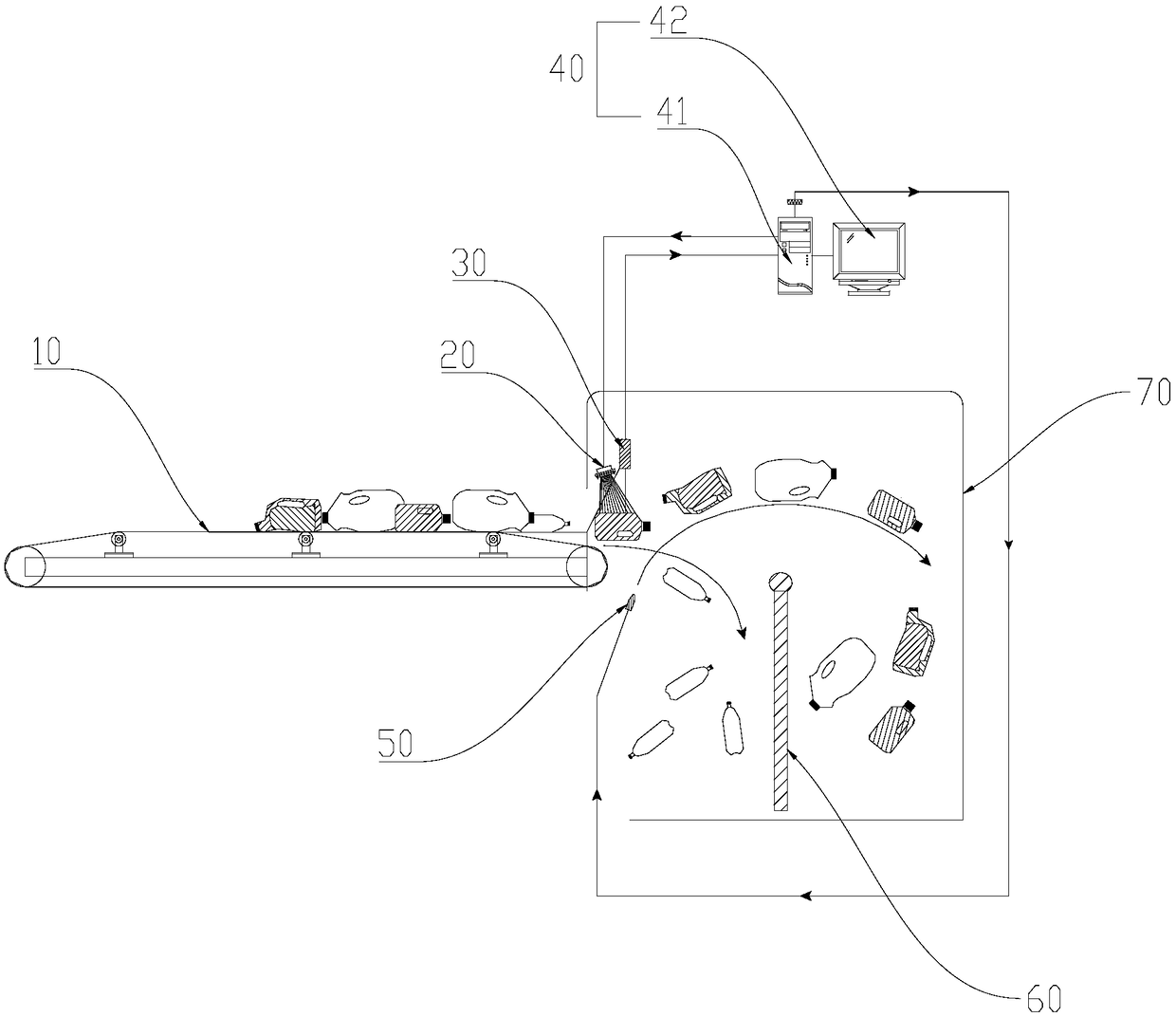

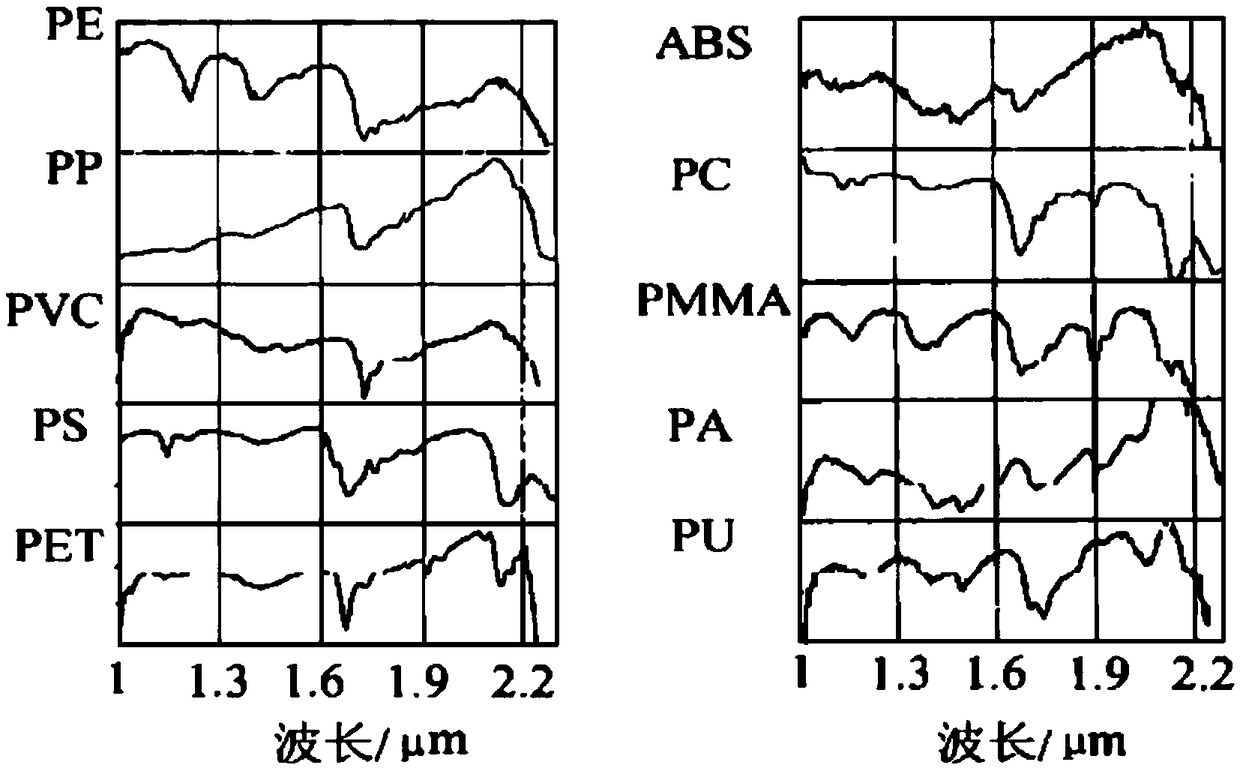

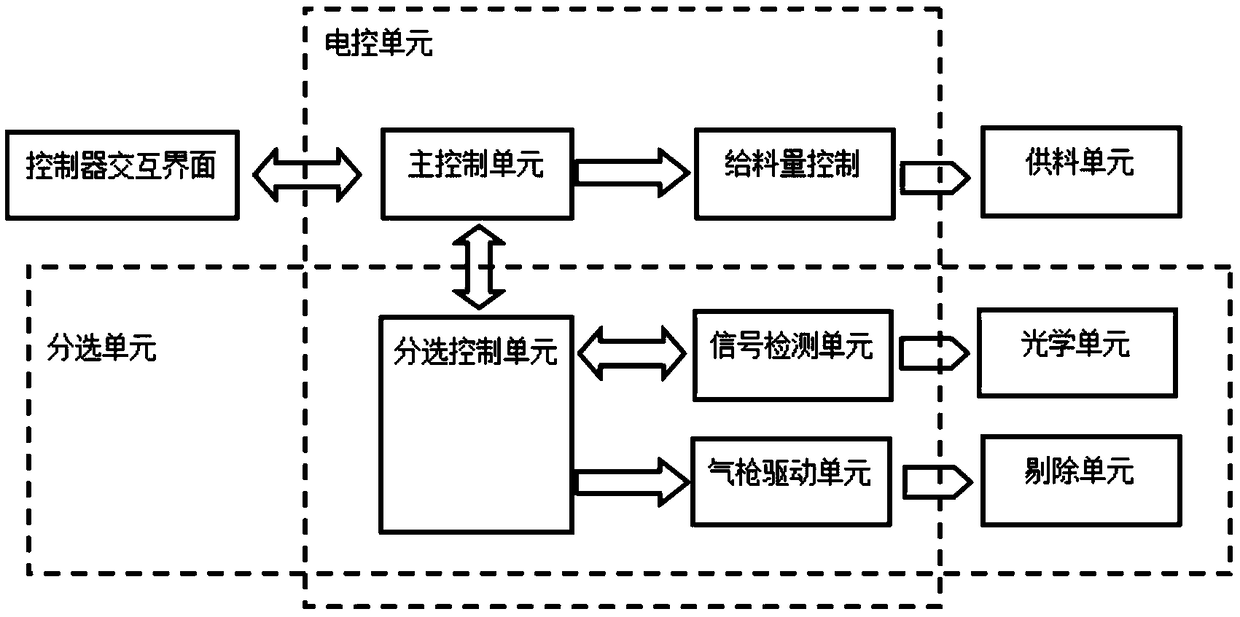

[0038] Such as Figure 1 to Figure 8 In the specific embodiment shown, the present invention discloses a sorting device for waste plastic types and a sorting method thereof; wherein, the sorting device for waste plastic types includes a conveying mechanism 10, which is located near the front edge of the conveying mechanism 10. The infrared scanning light source 20, the NIR photodetector 30 positioned at the front end of the near infrared scanning light source 20, the control mechanism 40 connected with the near infrared scanning light source 20 and the NIR photodetector 30, the high pressure jet mechanism 50 located at the front end of the conveying mechanism 10 below; The high-pressure air injection mechanism 50 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com