Method for manufacturing oil-water separation net with super-hydrophilic underwater super-oleophobic property

A technology of underwater super-oleophobic and oil-water separation mesh, applied in the field of preparation of oil-water separation mesh, can solve the problems of flux attenuation, secondary pollution, poor usability, etc., and achieve simple preparation process, easy cleaning, non-toxic and harmful effect of substance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment of the substrate: ultrasonically clean the 1000-mesh stainless steel mesh in ethanol and deionized water for 10 minutes, then dry it for later use;

[0028] (2) Preparation of reaction solution: Dissolve 0.346g of lanthanum nitrate hexahydrate in 20 ml of deionized water to form a 40 mmol / L lanthanum nitrate solution, then add 10 ml of 0.24 mol / L urea to adjust the pH to 2;

[0029] (3) The preparation process of the film layer: immerse the stainless steel mesh in (1) into the high-pressure reactor added with the reaction solution (2), keep it at 80°C for 20 hours, cool it down to room temperature naturally, take it out and blow dry at 550°C Annealed for 120 min.

Embodiment 2

[0031] (1) Pretreatment of the substrate: Ultrasonic cleaning of 800-mesh stainless steel mesh in ethanol and deionized water for 10 minutes, and then dried for later use;

[0032] (2) Preparation of reaction solution: Dissolve 0.087 g of lanthanum nitrate hexahydrate in 20 ml of deionized water to form a 10 mmol / L lanthanum nitrate solution, then add 10 ml of 0.10 mol / L urea to adjust the pH to 7;

[0033] (3) The preparation process of the film layer: immerse the stainless steel mesh in (1) into the high-pressure reactor added with the reaction solution (2), keep it at 100°C for 12 hours, cool it down to room temperature naturally, take it out and blow dry at 550°C Annealed for 100 min.

Embodiment 3

[0035] (1) Pretreatment of the substrate: ultrasonically clean the 400-mesh stainless steel mesh in ethanol and deionized water for 10 minutes, and then blow dry;

[0036] (2) Preparation of reaction solution: Dissolve 0.130 g of lanthanum nitrate hexahydrate in 20 ml of deionized water to form a 15 mmol / L lanthanum nitrate solution, then add 10 ml of 0.30 mol / L urea to adjust the pH to 3;

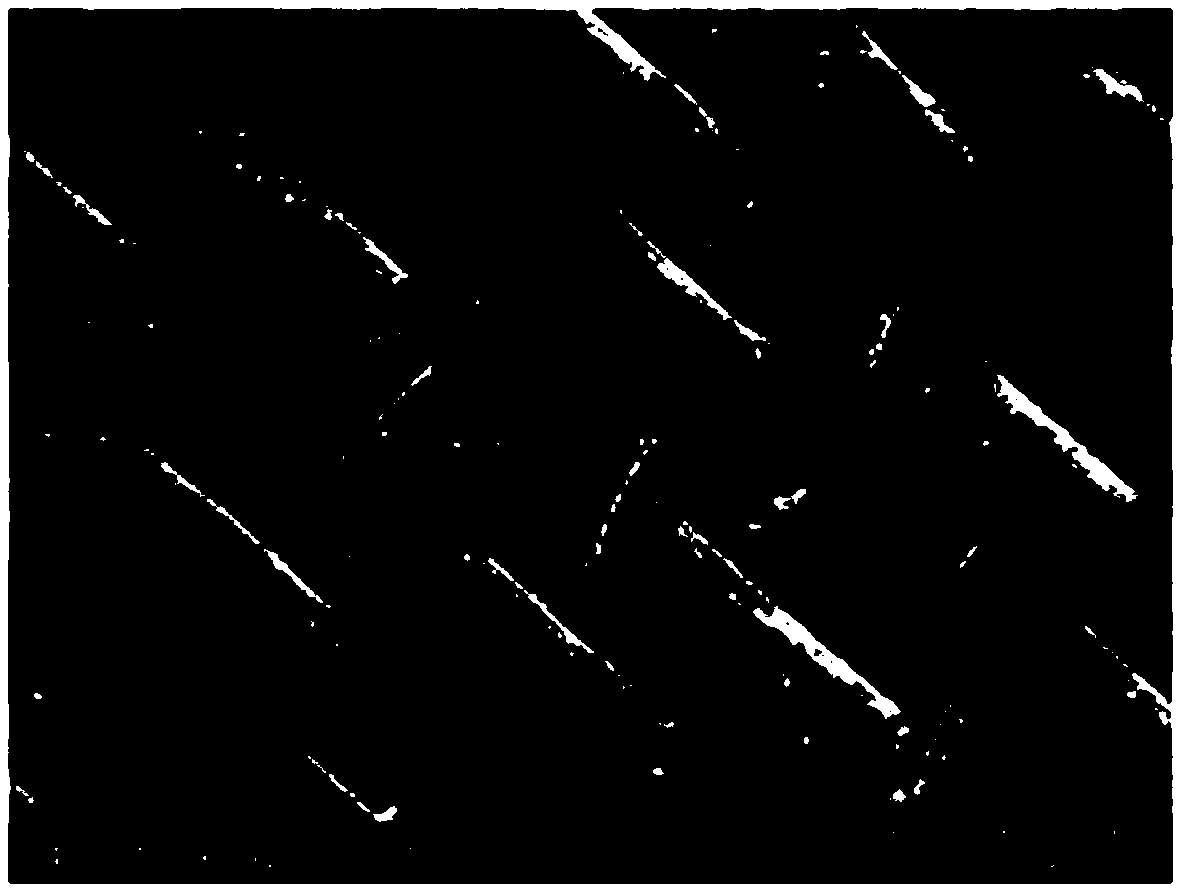

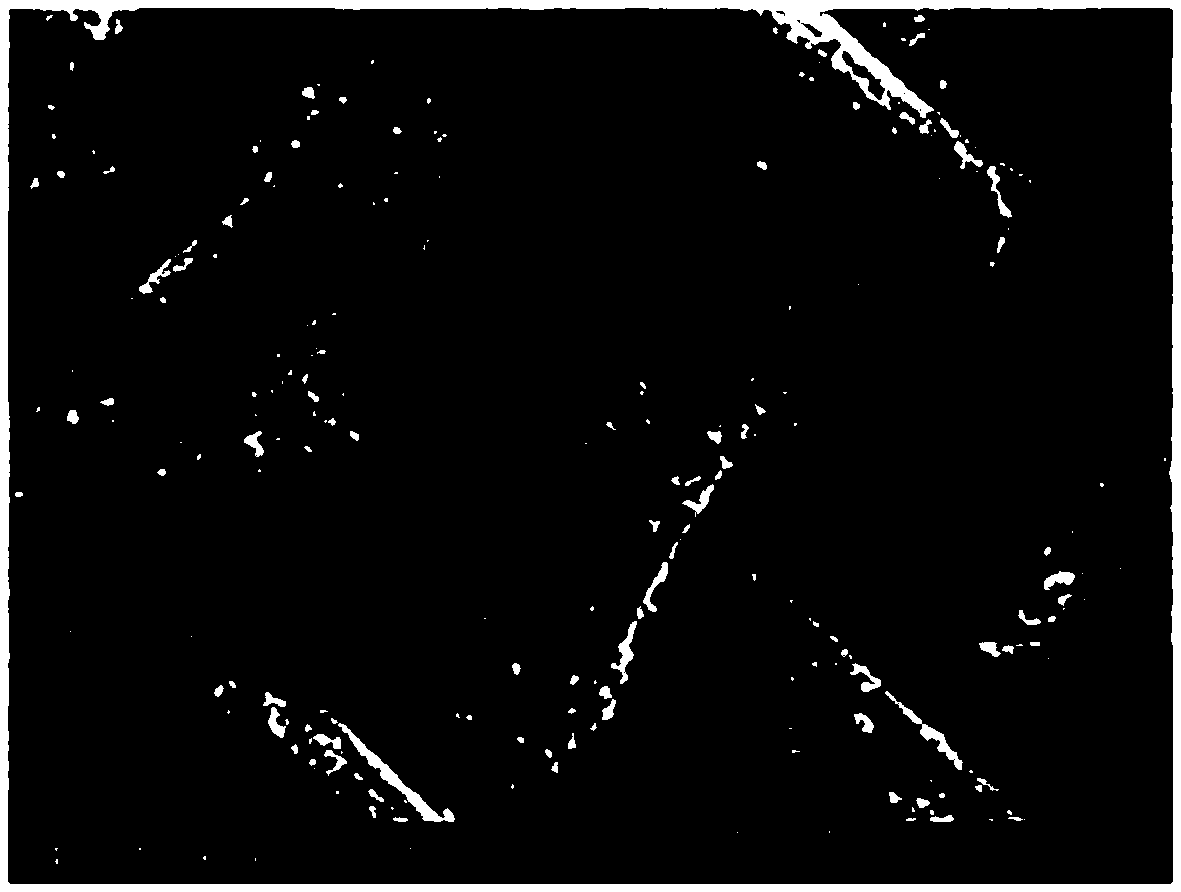

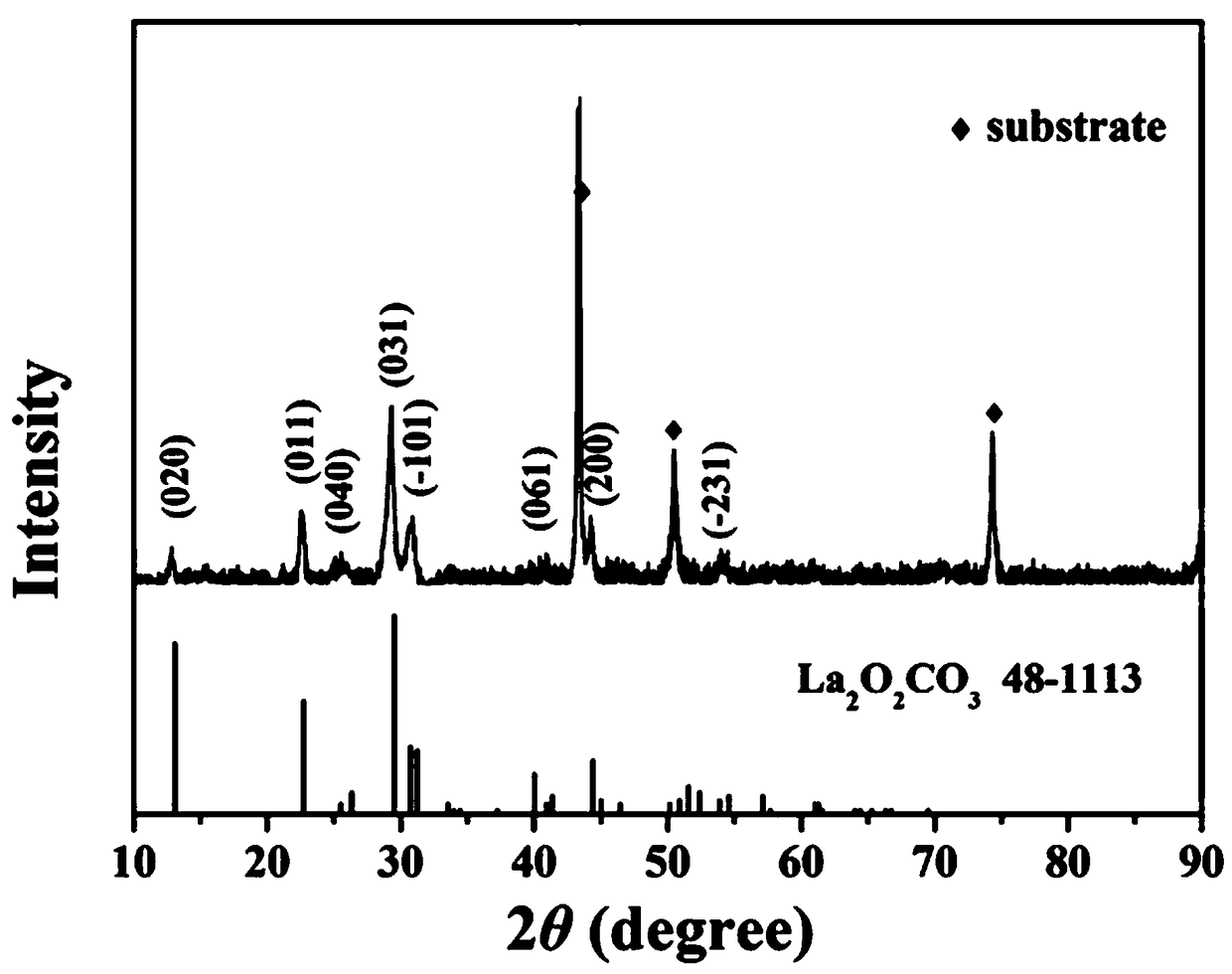

[0037] (3) The preparation process of the film layer: immerse the stainless steel mesh in (1) into the high-pressure reactor added with the reaction solution (2), keep it at 160°C for 5 hours, cool it down to room temperature naturally, take it out and dry it, and heat it at 550°C. ℃ annealing for 100 min to prepare lanthanum oxycarbonate (La 2 o 2 CO 3 ) micro-nanostructures (such as image 3 shown), the obtained oil-water separation mesh has a pore size of about 40 μm (as shown in figure 1 with figure 2 shown).

[0038] (4) The prepared oil-water separator has a contact angle of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com