Self-cleaning vacuum cleaner

A technology of vacuum cleaners and vacuum cleaners, which is applied in the direction of vacuum cleaners, devices for cleaning filters, cleaning equipment, etc., and can solve problems such as not finding vacuum cleaners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

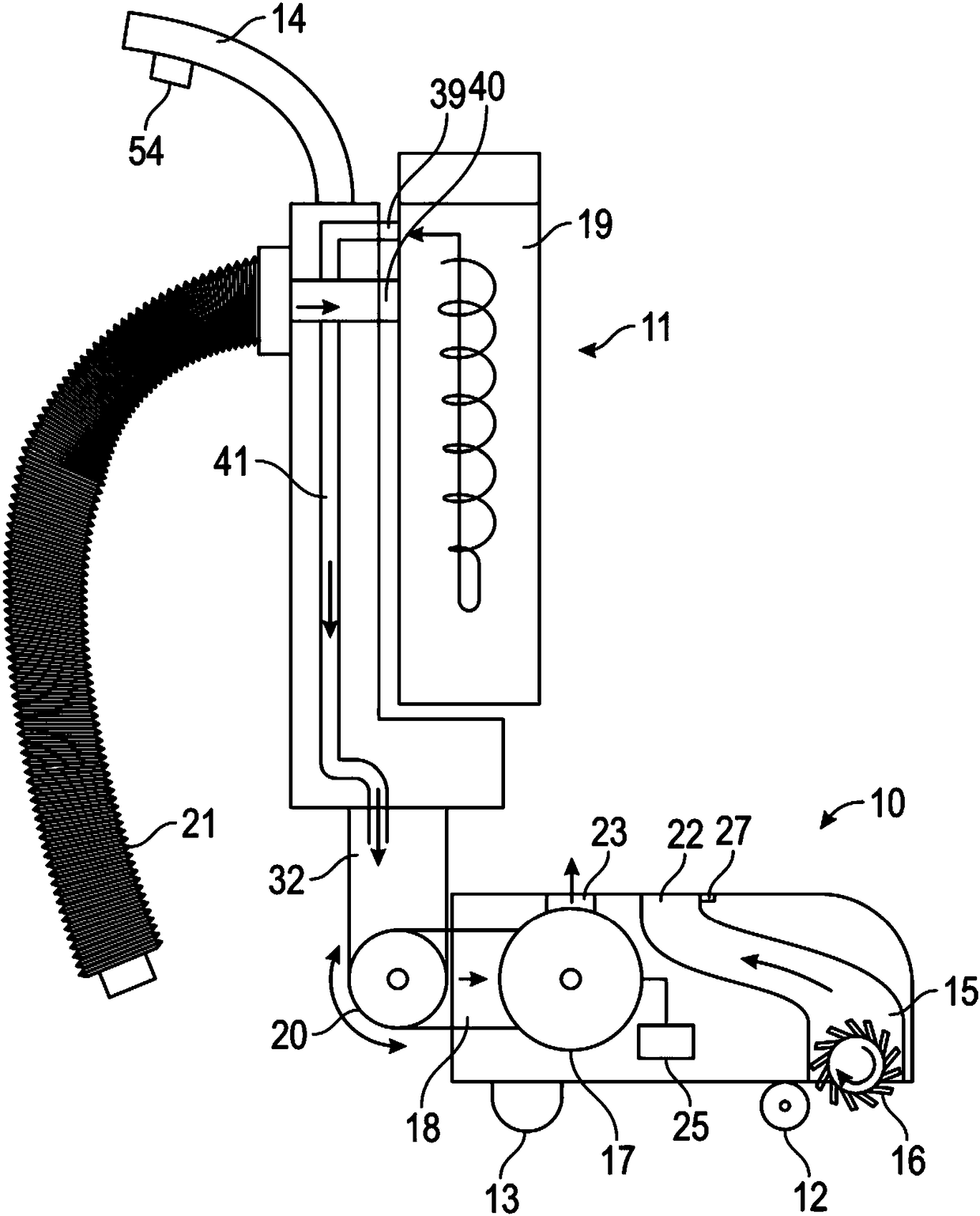

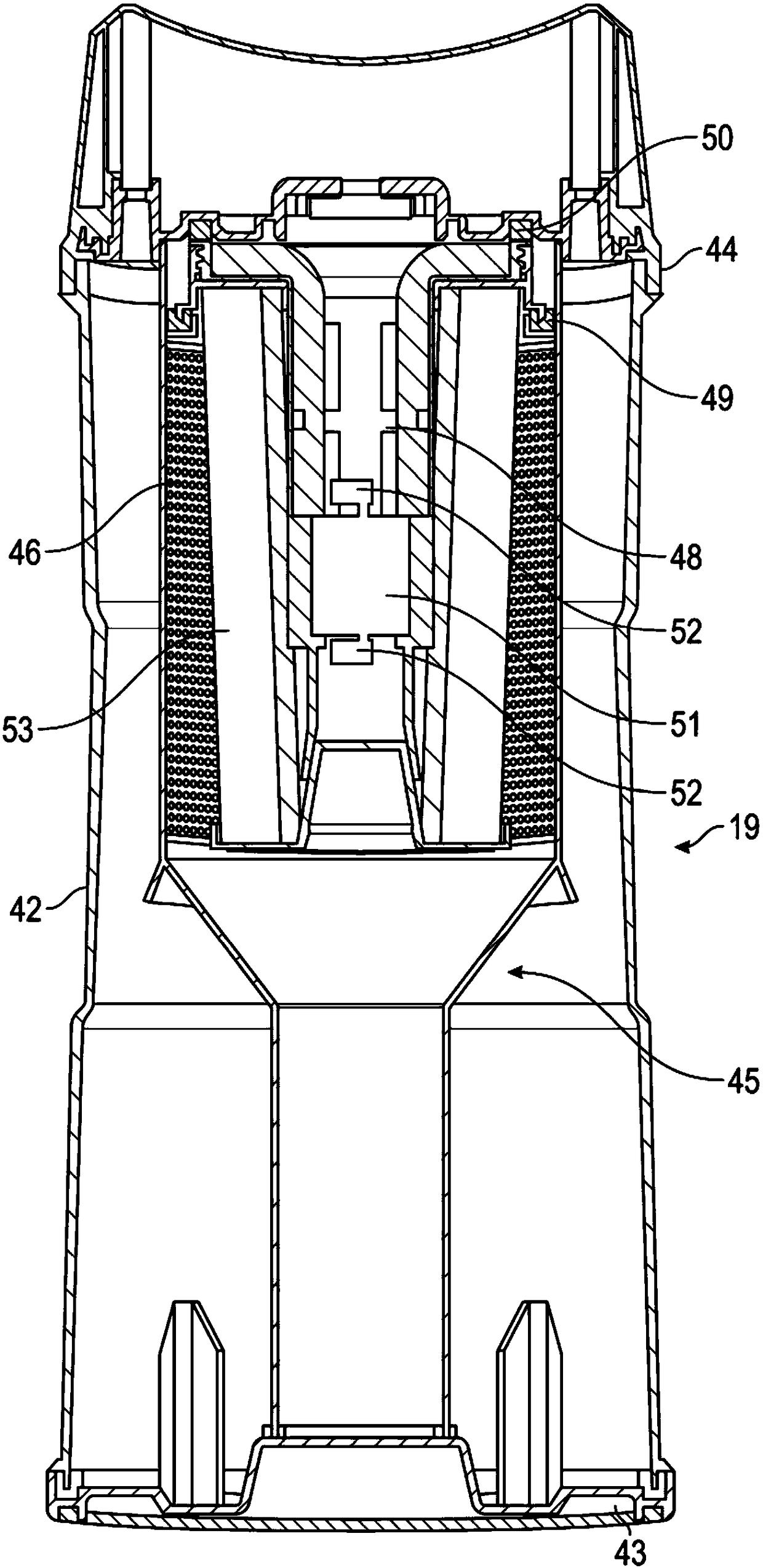

[0036] Reference attached figure 1 , shows an upright vacuum cleaner including a floor engaging head 10 supported by front and rear wheels 12,13. An upright body portion 11 is pivotally mounted to the rear of the head 10 and includes a handle 14 for guiding and maneuvering the cleaner on a floor surface. The head 10 includes an elongated transverse suction opening 15 positioned adjacent the front wheel 12 . A rotating agitating brush 16 extends across the suction inlet 15 for beating and sweeping the floor surface during cleaning.

[0037] A motor and fan unit 17 arranged in the head 10 drives the stirring brush 16 via a belt (not shown). The motor and fan unit 17 also generates a reduced air pressure in the duct 18 which is connected through the neck 20' to the clean air outlet duct 39 of the dust separation unit 19 which is detachably mounted on the main body 11 . In use, the body 11 is pivotable relative to the head 10 about this neck 20 acting as a node, between a rest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com