Multi-row garlic combine harvester

A harvester and garlic technology, which is applied to digging harvesters, harvesters, topping machines, etc., can solve the problems of low productivity, less than 1% of garlic machine area, poor operation quality and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

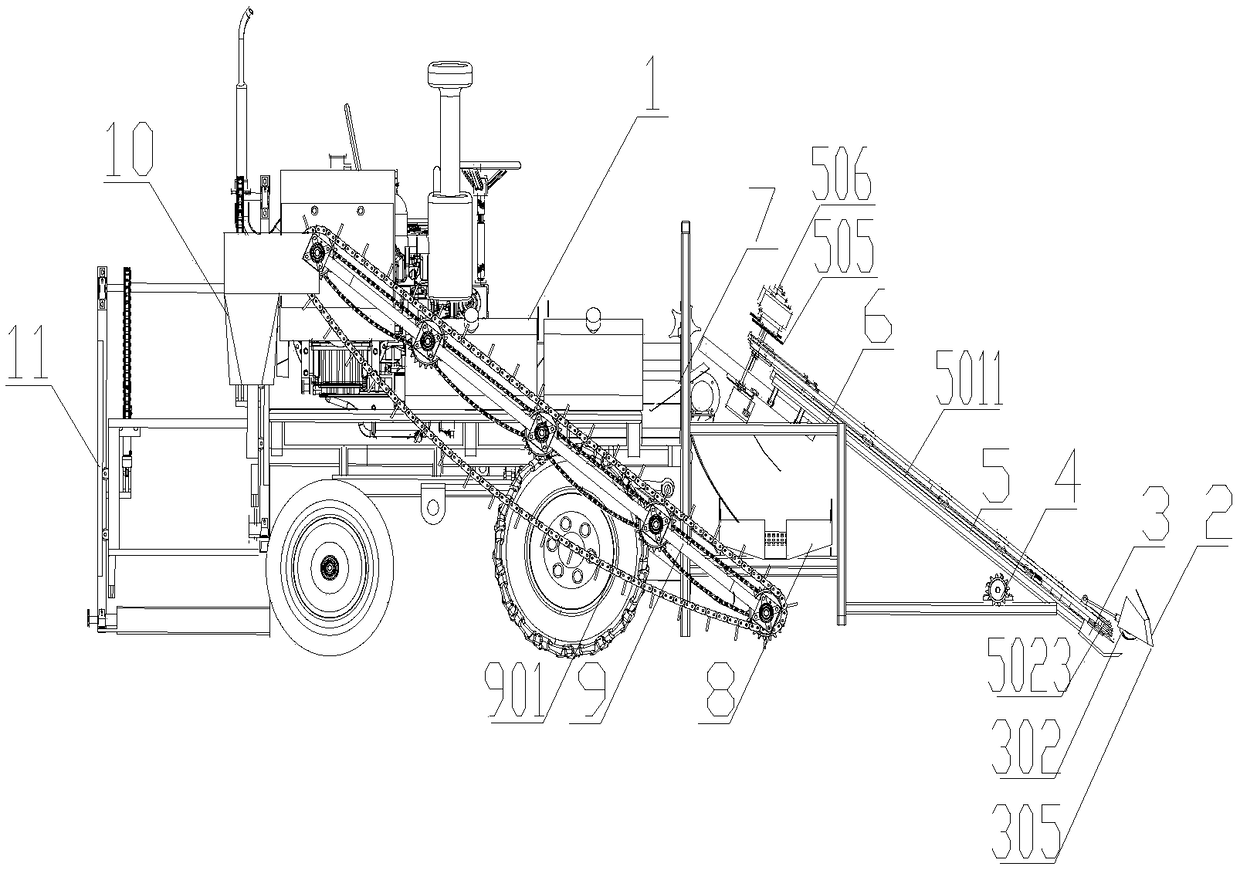

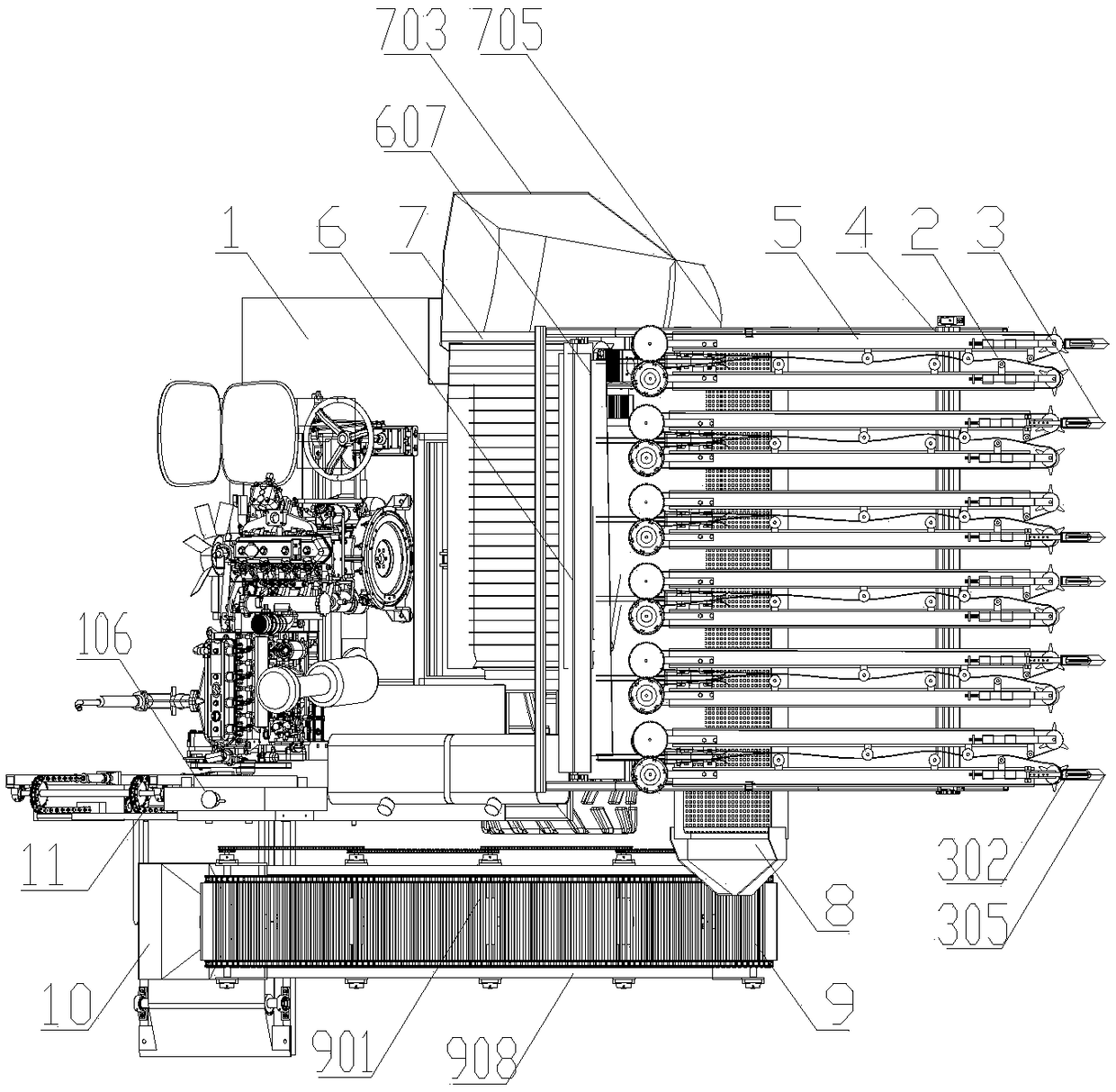

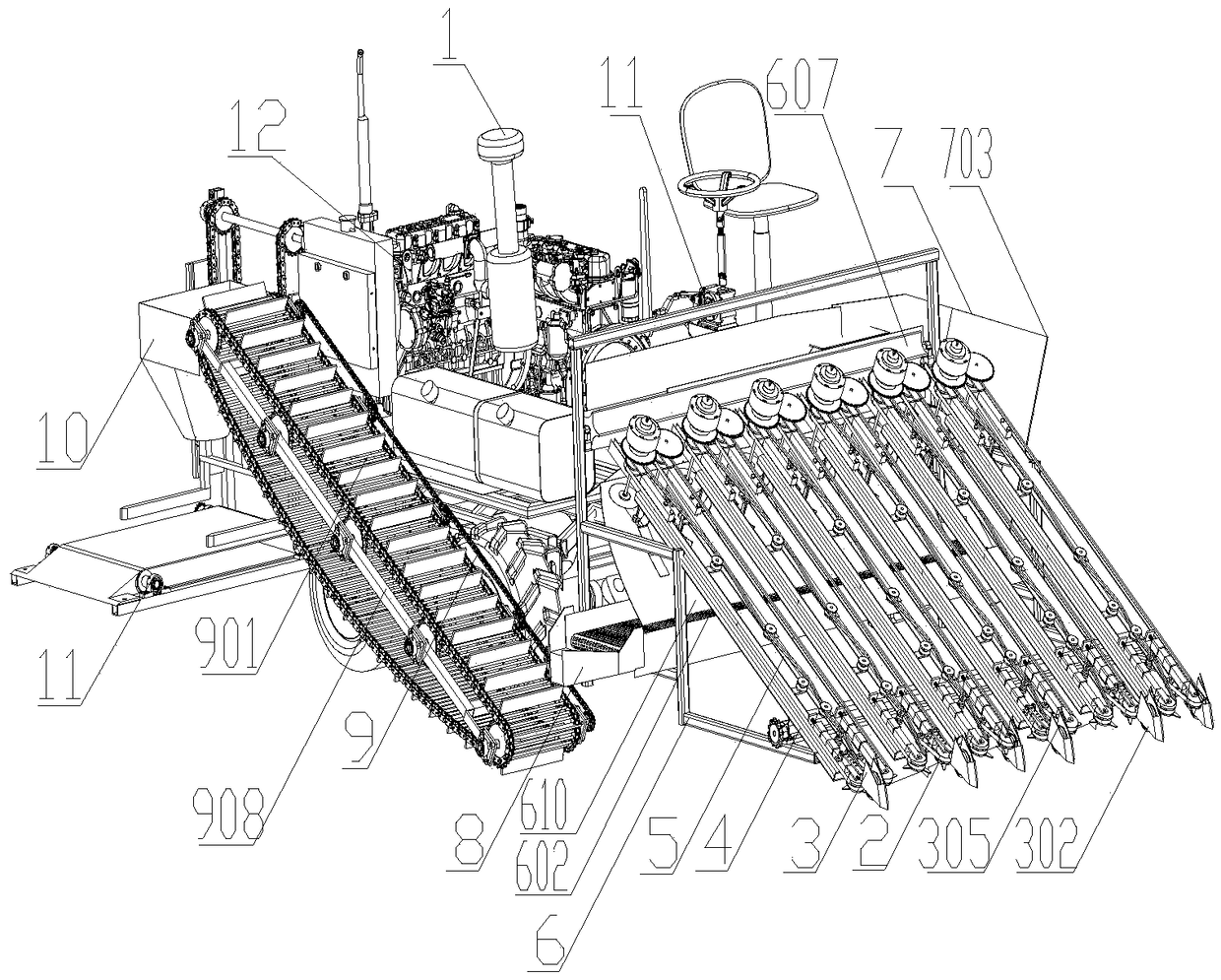

[0053] The following will refer to Figure 1 to Figure 25 Describe the working principle of a multi-row garlic combine harvester of the present invention.

[0054] like Figure 1 to Figure 25 As shown, the present invention includes the following parts:

[0055] The chassis 1 can use the existing mechanical drive chassis, and drive the chassis to walk through the engine and the gearbox (which can be completed by using the existing technology), as a platform for the power source of the whole machine, manual operation and other devices.

[0056] The digging shovel 2 can realize non-destructive and low-resistance digging of garlic through vibration digging.

[0057] The said harvesting device includes a grass-supporting protective cover 301, a depth-limiting wheel 302, a grass-supporting support 303, a grass-supporting fixed seat 304 and a grass-supporting rotating shaft 305; the harvesting device is located at the front end of the garlic harvester's forward direction and can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com