A kind of preparation method of carbon negative electrode plate

A technology of negative electrode and electrode plate, applied in the field of preparation of carbon negative electrode plate, can solve the problems of not being able to obviously improve the cycle performance of lead-carbon super battery, not supplying current, etc., so as to improve chemical stability, inhibit hydrogen evolution, process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

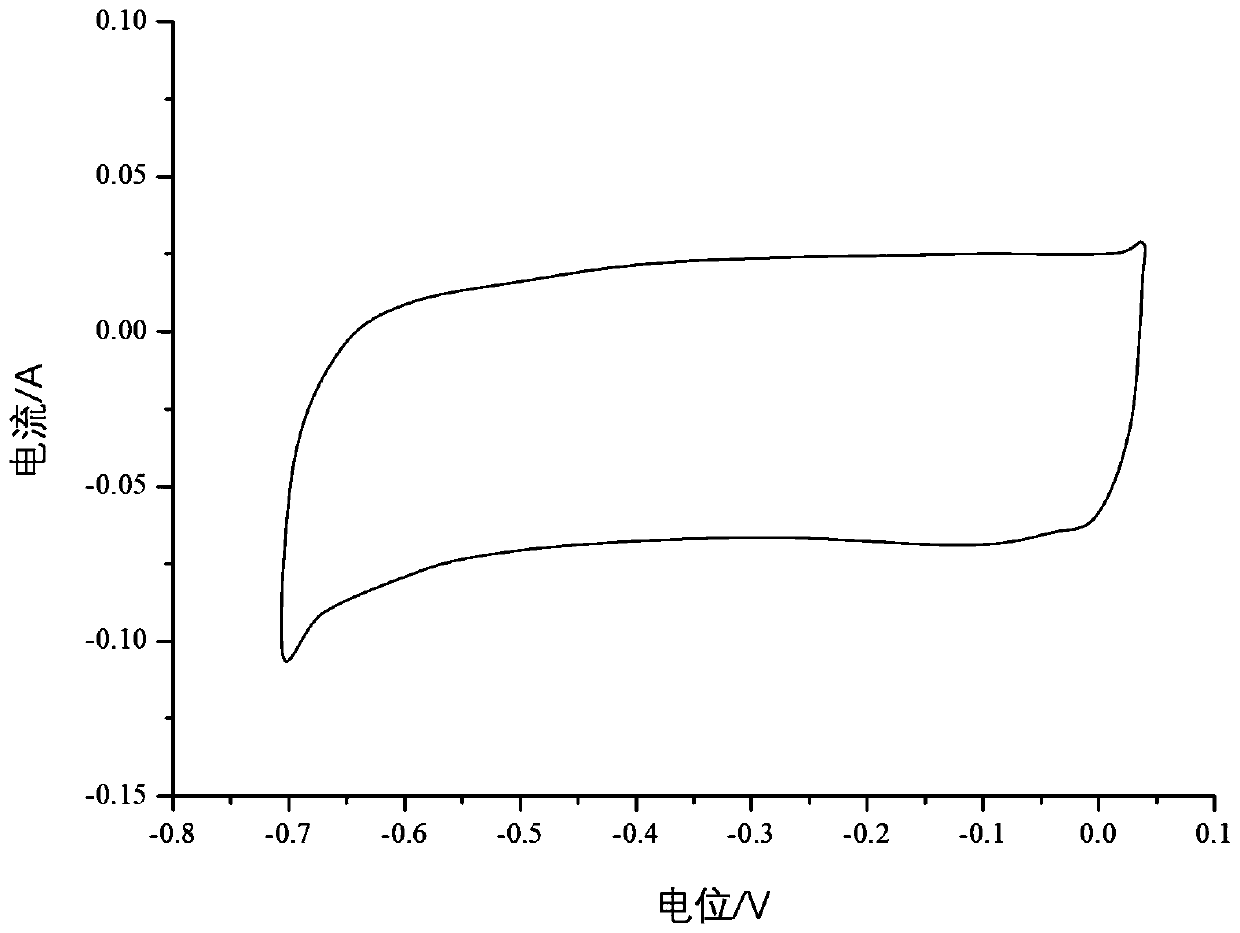

Image

Examples

Embodiment 1

[0033] 1) Preparation of polyaniline / activated carbon composites

[0034] Mix 2.0 g of activated carbon, 0.5 g of aniline, and 20 mL of 0.5 mol / L hydrochloric acid under normal temperature magnetic stirring to obtain a mixed solution A. Under the condition of magnetic stirring, add 25 mL of ammonium persulfate solution with a concentration of 0.5 mol / L to the above mixture A at a rate of 0.01 mL / s. After the addition, continue to react for 24 hours at a temperature of 0°C . After the reaction, the precipitate was filtered, washed repeatedly with 1mol / L hydrochloric acid and acetone, and dried in vacuum at 50°C for 24 hours to obtain a polyaniline / activated carbon composite material.

[0035] 2) Preparation of nitrogen-doped porous activated carbon

[0036] The polyaniline / activated carbon composite was soaked in 0.5% NH 4 In the Cl solution, shake in a water-bath shaker at 80°C for 5h, and dry in a blast drying oven at 60°C for 24h. The above-mentioned fibers were placed i...

Embodiment 2

[0044] 1) Preparation of polyaniline / activated carbon composites

[0045] Mix 2.0 g of activated carbon, 0.5 g of aniline, and 20 mL of 0.5 mol / L hydrochloric acid under normal temperature magnetic stirring to obtain a mixed solution A. Under the condition of magnetic stirring, add 25 mL of ammonium persulfate solution with a concentration of 0.5 mol / L to the above mixture A at a rate of 0.01 mL / s. After the addition, continue to react for 24 hours at a temperature of 0°C . After the reaction, the precipitate was filtered, washed repeatedly with 1mol / L hydrochloric acid and acetone, and dried in vacuum at 50°C for 24 hours to obtain a polyaniline / activated carbon composite material.

[0046] 2) Preparation of nitrogen-doped porous activated carbon

[0047] The polyaniline / activated carbon composite was soaked in 0.5% NH 4 In the Cl solution, shake in a water-bath shaker at 80°C for 5h, and dry in a blast drying oven at 60°C for 24h. The above-mentioned fibers were placed i...

Embodiment 3

[0055] 1) Preparation of polyaniline / activated carbon composites

[0056] Mix 2.0 g of activated carbon, 0.5 g of aniline, and 20 mL of 0.5 mol / L hydrochloric acid under normal temperature magnetic stirring to obtain a mixed solution A. Under the condition of magnetic stirring, add 25 mL of ammonium persulfate solution with a concentration of 0.5 mol / L to the above mixture A at a rate of 0.01 mL / s. After the addition, continue to react for 24 hours at a temperature of 0°C . After the reaction, the precipitate was filtered, washed repeatedly with 1mol / L hydrochloric acid and acetone, and dried in vacuum at 50°C for 24 hours to obtain a polyaniline / activated carbon composite material.

[0057] 2) Preparation of nitrogen-doped porous activated carbon

[0058] Soak the polyaniline / activated carbon composite in a mass concentration of 1% NH 4 In the Cl solution, shake in a water-bath shaker at 80°C for 5h, and dry in a blast drying oven at 60°C for 24h. The above-mentioned fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com