Magnetic levitation thermobalance based on rapid temperature rise of light and heat

A magnetic levitation and thermal balance technology, applied in the direction of weighing by removing a certain component, can solve the problems of limited application, test pressure and atmosphere limitation, slow heating rate, etc., to achieve stable and safe experimental process and reduce system complexity. , the effect of reducing systematic errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as Figure 1~4 As shown, the magnetic levitation thermal balance based on photothermal rapid temperature rise designed in this embodiment includes a closed container 1, a reaction cell 601, a magnetic levitation device, a stator lifting assembly 8, a laser displacement monitoring assembly 10, a photothermal heating assembly 9 and a photothermal Warming component displacement device 903, wherein:

[0039] The airtight container 1 is cylindrical, with a gas inlet 2 at the center of the top end, and a detachable cover plate 12 (fixed by bolts) at the lower end. Two gas outlets 11 are symmetrically arranged on the cover plate 12. The airtight container 1 The interior is provided with a pressure monitoring component 4, an airflow stabilizing device 3, and an infrared temperature measuring component 5, and the side wall is provided with a displacement monitoring window 102 made of a transparent material and a heating beam window 101 made of a transparent material. The a...

Embodiment 2

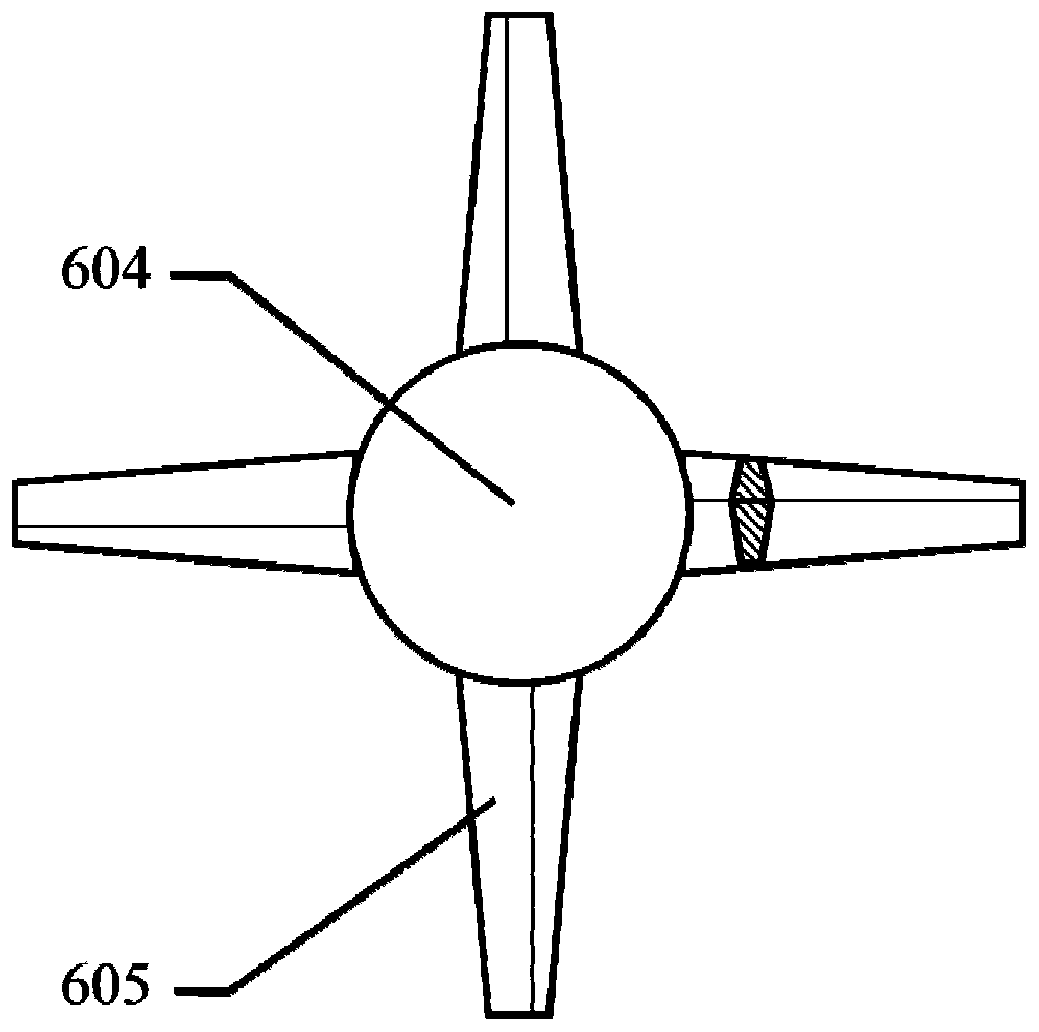

[0047] Such as Figure 5 As shown, the structure of embodiment 2 is substantially the same as that of embodiment 1, and the only difference is: 1) embodiment 2 is also provided with a microscope 13 and a Raman laser 14 at the center of the lower part of the airflow stabilizing device 3; 2) embodiment 2 is not provided A special stator lifting component 8, the position of the stator is manually adjusted through the fixture; 3) The photothermal heating component 9, the heating beam window 101, the laser displacement monitoring component 10, and the displacement monitoring window 102 are all 4 in number, respectively arrayed around Around the maglev buoy 603, Figure 6 The positional relationship between the photothermal heating component 9 and the magnetic levitation float 603 is given when looking down from the upper part; 4) In this embodiment, the infrared temperature measurement component 5 adopts SIMA instrument AT1350, and the laser displacement monitoring component 10 ado...

Embodiment 3

[0049] This embodiment discloses a method for carrying out a thermogravimetric analysis experiment using a magnetic levitation thermobalance in embodiment 1 or embodiment 2, and the steps are as follows:

[0050] 1) Weigh the mass as g 0 The measured materials are sent to the reaction pool 601;

[0051] 2) Remove the cover plate 12, place the reaction pool 601 on the support frame 602 of the magnetic levitation float 603, then place the magnetic levitation float 603 on the center of the cover plate 12, install the cover plate 12 on the airtight container 1, and adjust the magnetic levitation stator 7 The position makes it be located directly below the center of the rear cover plate 12 after installation;

[0052] 3) Start the magnetic levitation device, and after the magnetic field is stable, move the magnetic levitation stator 7 upwards, so that the magnetic levitation float 603 is suspended in the airtight container 1;

[0053] 4) Continuously feed the gas needed to mainta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com