Method for detecting leakage of air compressor and detection device thereof

An air compressor and detection device technology, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of insufficient resources of the engine factory test bench and the inability to leak the air compressor. The problems of low testing and testing efficiency, to achieve the effect of fast and convenient testing, simple structure, and speeding up the testing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

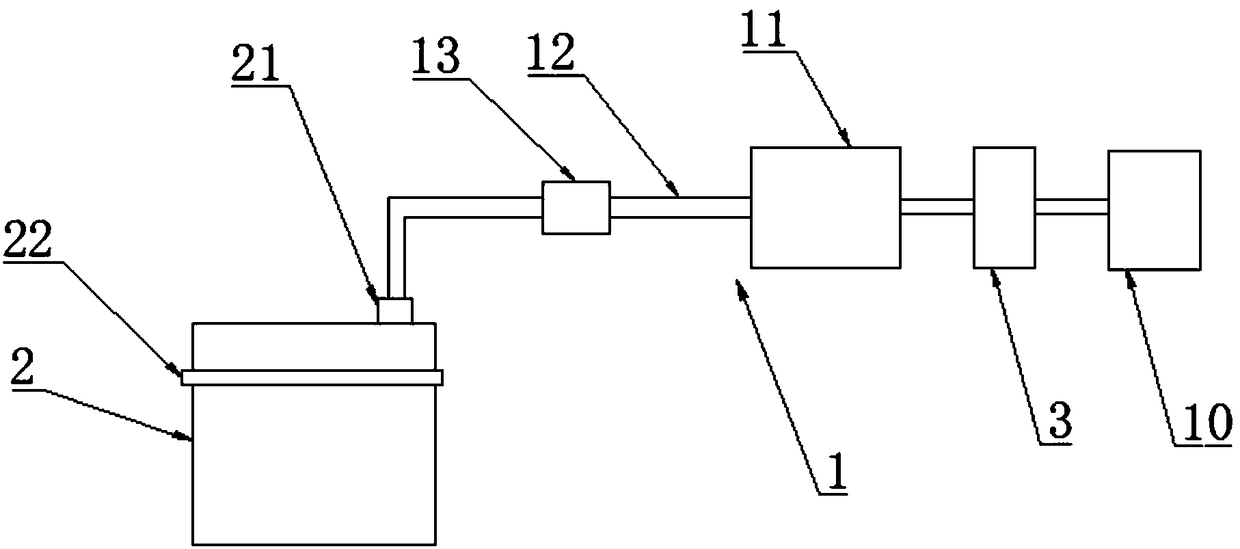

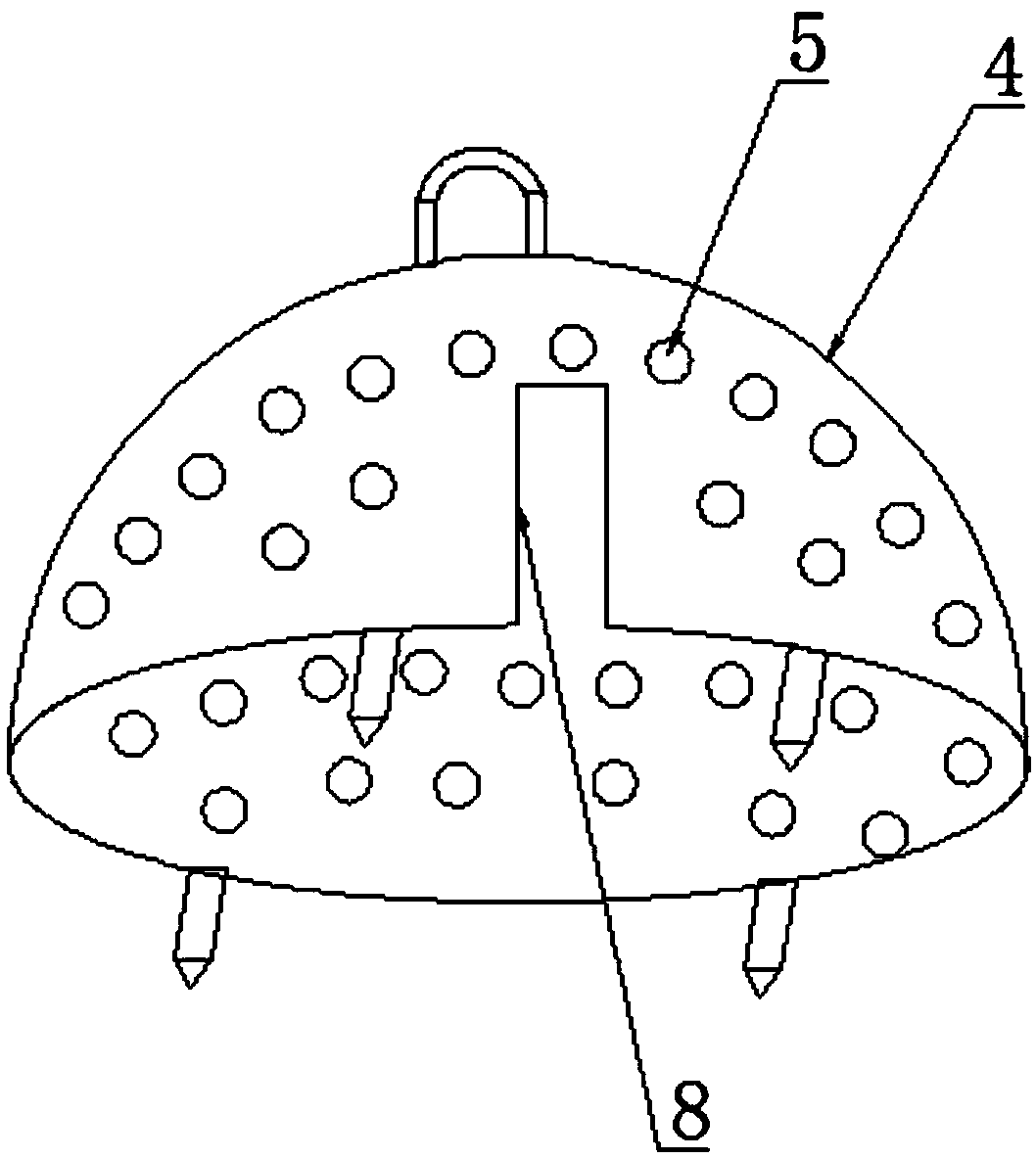

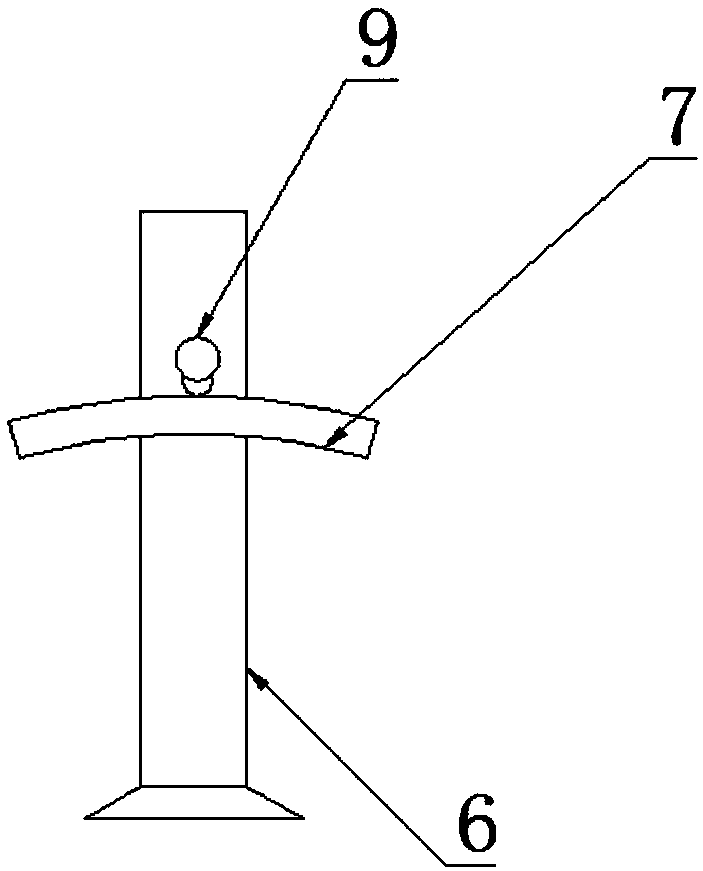

[0022] The specific embodiment of the present invention is like this: as Figure 1-3 As shown, a method for detecting leakage of an air compressor includes the following steps: firstly, a pressurizing device 1 is connected to the air source equipment 10, and then the pressurizing device 1 is connected to the air outlet joint 21 of the air compressor 2 Input the high-pressure air source to the air outlet cavity of the air compressor 2, and set the air source triple piece 3 between the pressurizing device 1 and the air source equipment 10 for air source treatment; finally use the soap solution foaming method to detect the air compressor 2 Whether there is air leakage; according to the working load of the air compressor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com