Method for measuring weight moment of turbine blade of gas turbine

A turbine blade and measurement method technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems that the weight moment cannot be accurately measured and cannot be directly measured, and the measurement method is simple and practical. The effect of low probability of error and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

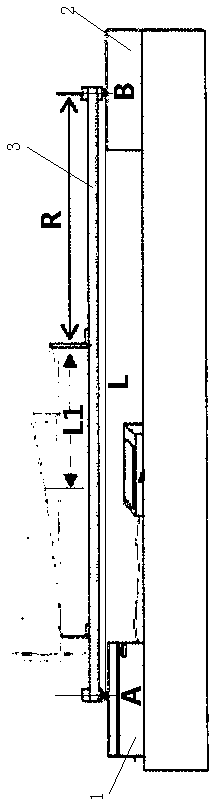

[0025] Such as figure 1 As shown, the method for measuring the weight moment of a turbine blade of a gas turbine disclosed by the present invention is mainly aimed at fast and accurate measurement of blades of a small gas turbine, and specifically includes the following steps:

[0026] Step 1. Place an electronic scale 1 and a boss 2 respectively on a horizontal plane with a certain distance between them, and the upper surface of the electronic scale and the boss are located on the same horizontal plane;

[0027] Step 2. Set up the two ends of the blade placing platform 3 on the electronic scale and the boss respectively, the supporting point with the electronic scale is A, and the supporting point with the boss is B, and the placing platform is in a horizontal state at this time;

[0028] Step 3. Adjust the value displayed on the electronic scale to zero to ensure that the weight value of the subsequent weighing does not include the weight of the placement platform, and then ...

no. 2 example

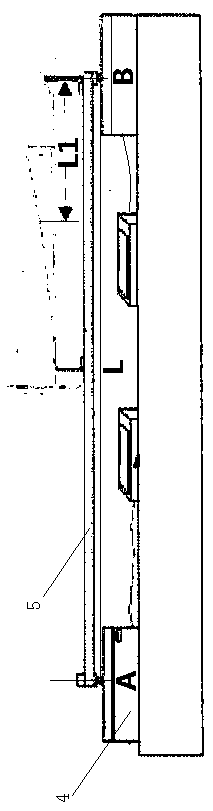

[0031] Such as figure 2 As shown, the method for measuring the weight moment of a turbine blade of a gas turbine disclosed by the present invention is mainly aimed at fast and accurate measurement of blades of heavy-duty gas turbines. Due to the increase in size and weight of heavy-duty gas turbine blades, the radius of gyration Also increase, if also adopt the form of first embodiment to measure, just need to place the length of platform to increase, in order to ensure the measuring range of electronic scale, what usually adopts for placing platform is the aluminum alloy material processing with lighter quality, If its length increases, it will cause bending deformation during the measurement process, which will affect the measurement accuracy. Therefore, for the measurement of the central gas turbine impeller, the method of this embodiment is adopted, which specifically includes the following steps:

[0032] Step 1. Place the two electronic scales 4 respectively on a horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com